Hydrostatic support actuator

Core technology of Sinotest, the seceret of long using life

Home>>Accessories>>Hydrostatic bearing actuator

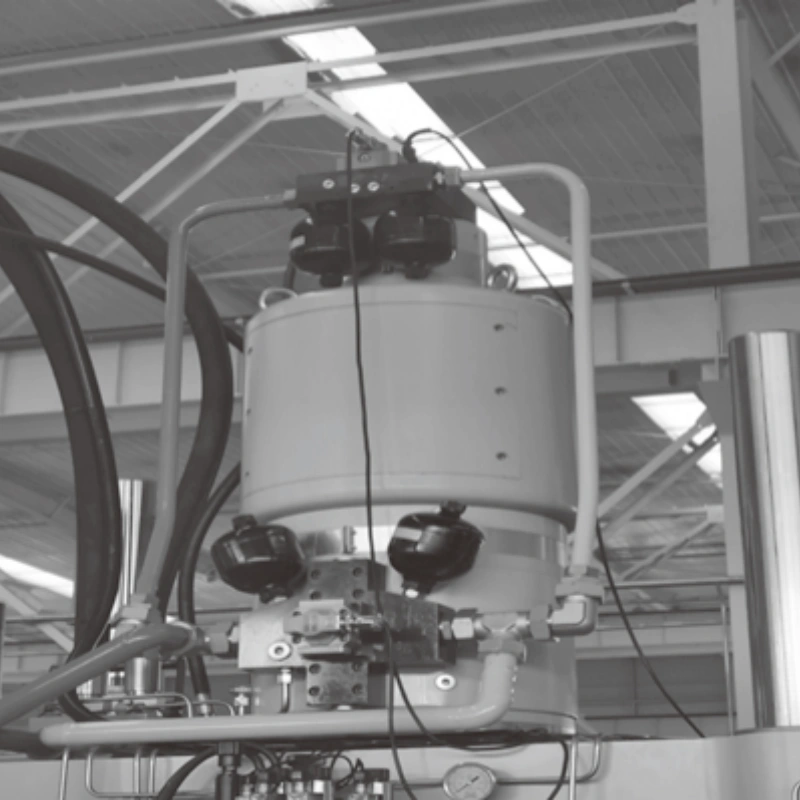

Hydrostatic bearing actuator

Core technology of Sinotest, the seceret of long using life

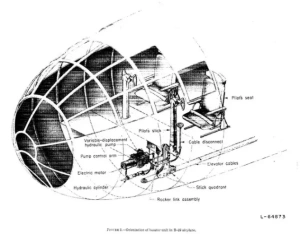

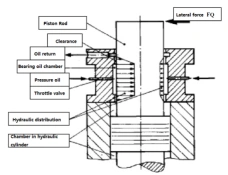

Hydrostatic bearing actuator has no sealing gaskets. With the help of special designed hydrostatic bearing unit, the piston rod automatically regulates itself that ensures constantly alignment between piston rod and cyinder housing and central guiding.

While bearings center the piston, all sliding surfaces in actuator are separated by oil film under pressure; this oil film in hydrostatic bearings exists before piston moves and is maintained even under lateral force so to exclude friction & wear. Hydrostatic bearing actuator offers much high performance and fits in well with testing tasks where high accuracy of control and measurement is essentially desired.

Parameters:

- Capacity: 10kN-20000kN

- Frequency: 0.01-400Hz

- Working pressure: 21MPa/28MPa

- Speed: 6m/s, customized up to 20m/s

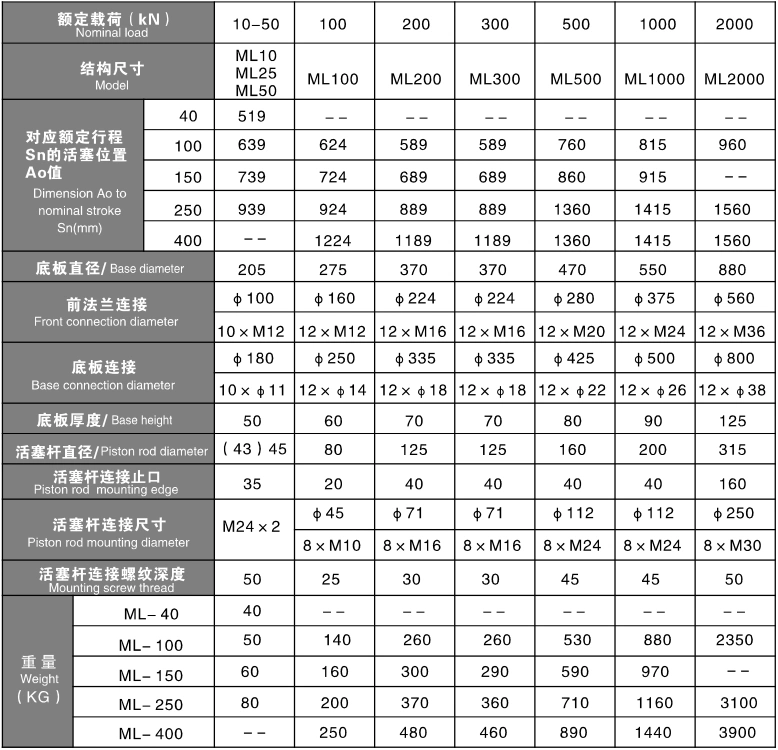

AVAILABLE MODELS

ML series hydrostatic torsion servo actuator

Capacity(10-20000kN)

- ML10/25/50

- ML100/200/300/500

- ML1000/2000

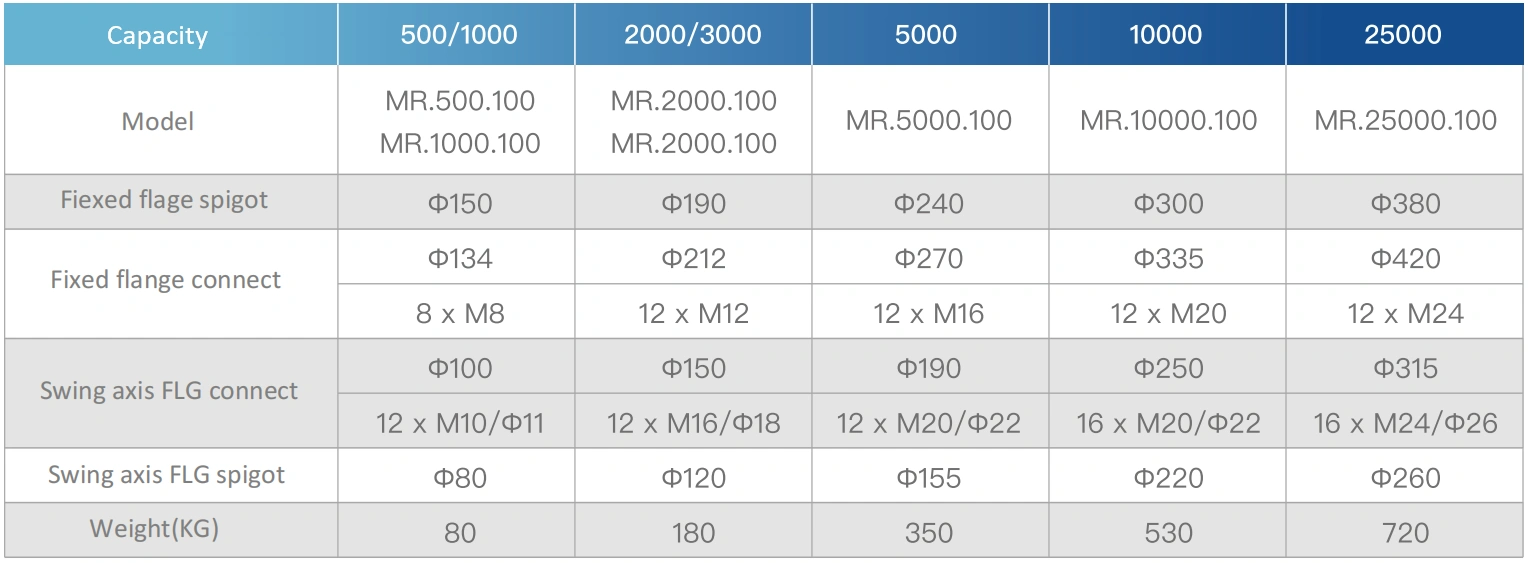

MR series hydrostatic liner servo actuator

- MR.500/1000.100

- MR.2000/3000.100

- MR.5000.100

- MR.10000.100

- MR.25000.100

Application

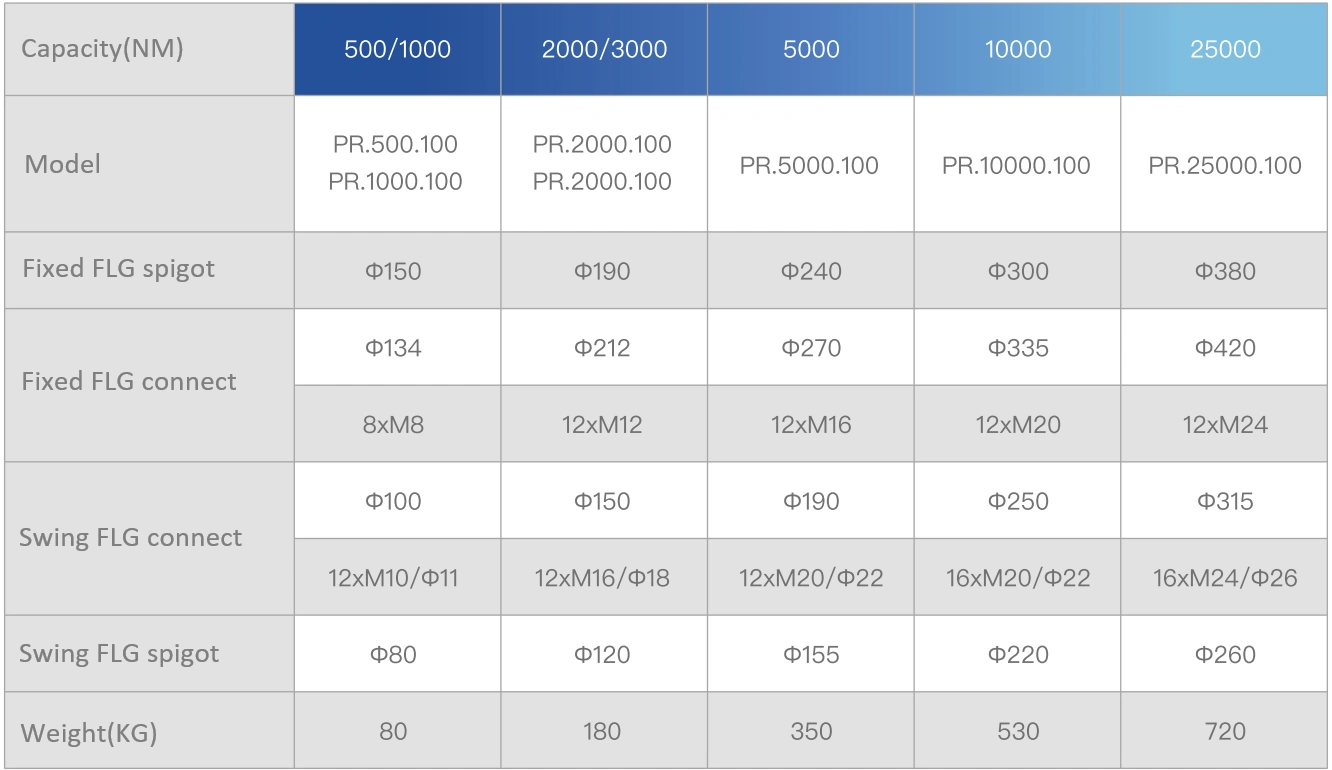

Detailed Technical Specification

Feature

- ML series

- The relative sliding surface has almost no friction, and the starting pressure is ≤ 0.001MPa;

- Featuring high frequency response, high speed, and long lifespan, the working frequency can reach up to 400Hz, the speed can reach up to 6m/s, and the uninterrupted working lifespan can exceed 100000 hours;

- Capable of high lateral load resistance, the piston rod can withstand a lateral load of 5% of the rated load when in the neutral position;

- hydrostatic bearings are always in a pure liquid lubrication state, with high transmission efficiency; Featuring high sensitivity, high control accuracy, good accuracy retention, and high motion precision;

- The relative sliding surface between the hydrostatic bearing and the piston rod is filled with a high stiffness and high load-bearing hydrostatic support oil film, which keeps the piston rod in the center position of the hydrostatic bearing at all times, with high seismic resistance, high coordination and synchronization, and automatic centering function;

- The special self-lubricating coating makes the hydrostatic support servo actuator repairable.

- MR series

- The swing servo actuator adopts hydrostatic bearings for sealing the oil chamber, which has the characteristics of high speed, high precision, and no friction. The working frequency can reach 300Hz, and the swing angle is ± 50 °. It can be customized according to user needs.

- The relative swinging surface has almost no friction;

- Characterized by high frequency response, high speed, and long lifespan;

- hydrostatic bearings are always in a pure liquid lubrication state, with high transmission efficiency, high sensitivity, high control accuracy, good precision retention, and high motion accuracy;

- Has high seismic resistance and high coordination synchronization;

- The special self-lubricating coating has repairability.

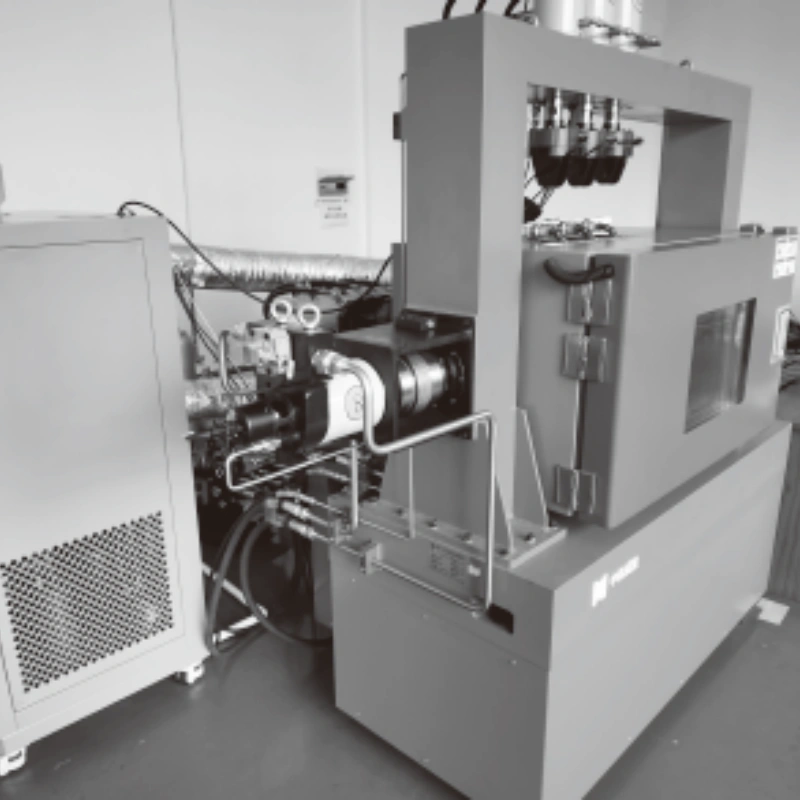

- PL series

- The dynamic electro-hydraulic servo linear actuator produced by our company is a device that generates force and displacement in the electro-hydraulic servo system, and is a key component for dynamic loading. Mainly used in the fields of dynamic, static, and fatigue testing. The dynamic electro-hydraulic servo linear actuator is mainly composed of servo cylinders, displacement sensors, servo valves, etc., which can achieve various closed-loop controls.

- Our company’s latest developed electro-hydraulic servo linear actuator is manufactured according to the standard hydrostatic servo actuator manufacturing process. Its external dimensions and related connection dimensions are completely consistent with the standard hydrostatic servo actuator, and its dynamic characteristics and service life are comprehensively superior to traditional friction pair servo actuators.

- Manufacturing process using hydrostatic servo actuator;

The external dimensions are completely consistent with the hydrostatic servo actuator; - The dynamic characteristics are superior to traditional friction pair servo actuators;

- Long service life and good sealing performance;

- The cylinder body has high strength and is not prone to resonance;

- Adopting gap sealing technology and special self-lubricating coating, the friction force of the servo actuator is smaller than that of traditional friction pairs;

- High cost-effectiveness.

- PR series

- The swing servo actuator is manufactured according to the manufacturing process of hydrostatic technology, and its external dimensions and related connection dimensions are completely consistent with the standard hydrostatic swing servo actuator. Its dynamic characteristics and lifespan are comprehensively superior to traditional friction pair swing servo actuators.

- Manufacturing process using hydrostatic bearingtechnology;

- The external dimensions are completely consistent with the hydrostatic bearingswing servo actuator;

- The dynamic characteristics are superior to traditional friction pair actuators;

- Long service life and good sealing performance;

- The cylinder body has high strength and is not prone to resonance;

- Adopting gap sealing technology and special self-lubricating coating, with low friction force;

- High cost-effectiveness.

▪FOB

▪CIF

▪Package: Wooden case

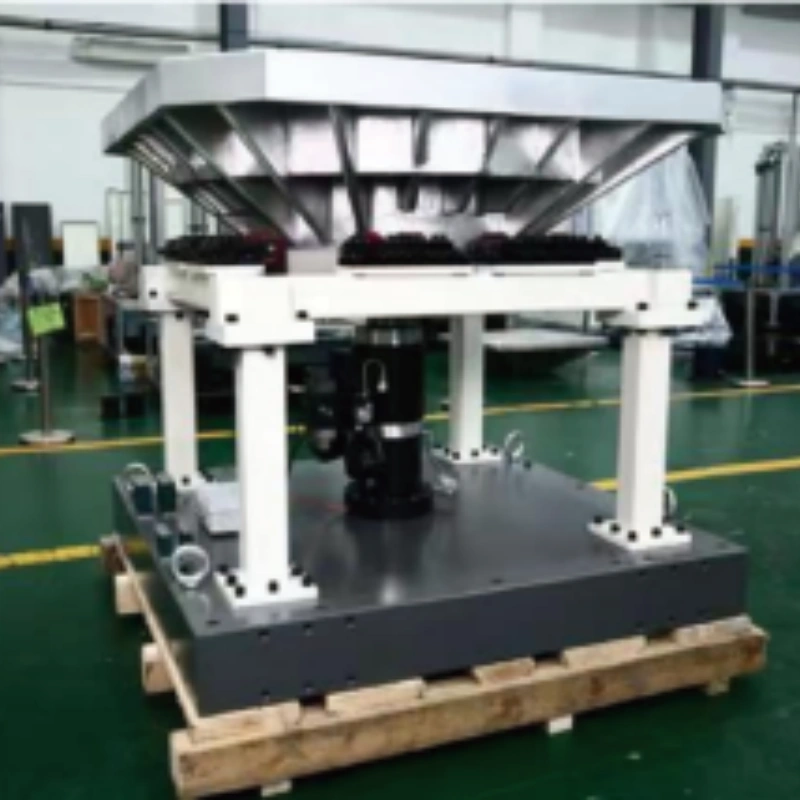

HYDROSTATIC DERIVATIVES

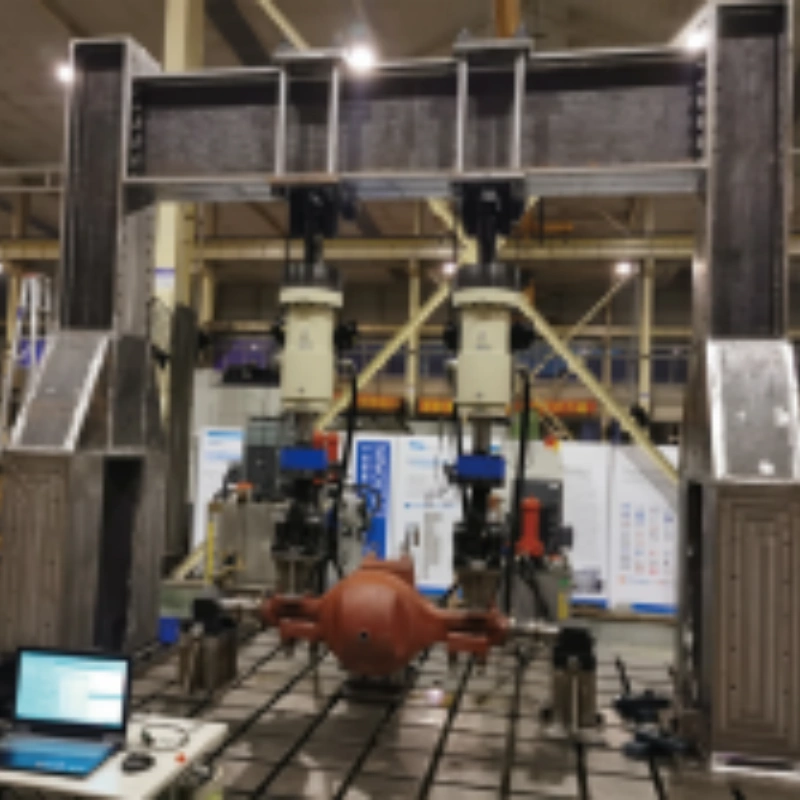

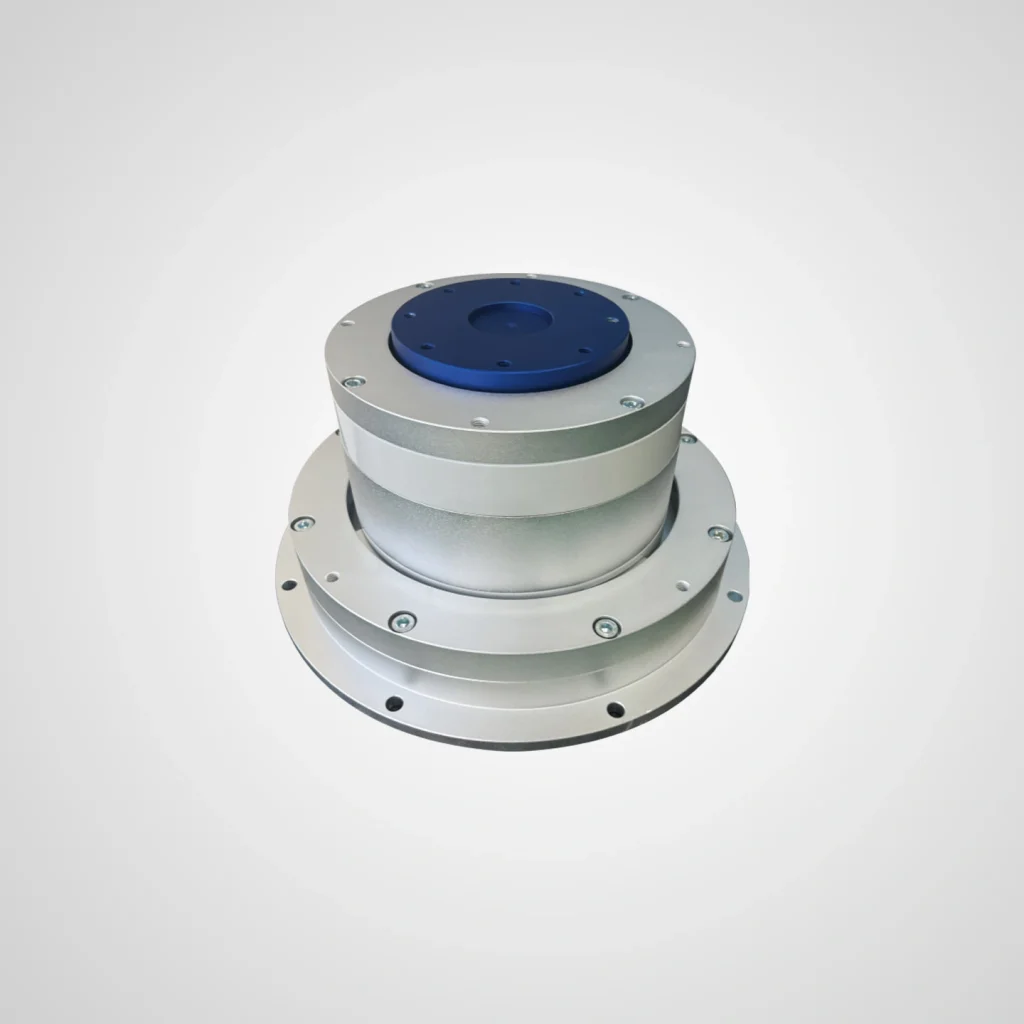

Low friction multi degree of freedom decoupling platform

Fully master the hydrostatic wear reduction technology of multi free decoupling platform, based on the hydrostatic decoupling platform, provide hydrostatic wear reduction components to improve accuracy and extend service life.

LARGE COMPREHENSVE PRODUCTS:

- Liquid hydrostaticamplifier

- Liquid hydrostatic balance

- Liquid hydrostaticoil and gas support

Release constraints

- (One degree of freedom)

Rotating bearing products, long-life accompanying test bearings, high stiffness support bearings, low friction ball bearings, and low friction guide sleeves. - (Two degrees of freedom)

Flat sliding table products, horizontal vibration table, compression shear platform, wear reducing sliding shoes, major equipment and scientific instrument rotary table. - (Three degrees of freedom)

Spherical hydrostatic turntableSpherical flipping products, attitude simulators, multi degree of freedom decoupling, hydrostatic ball products.

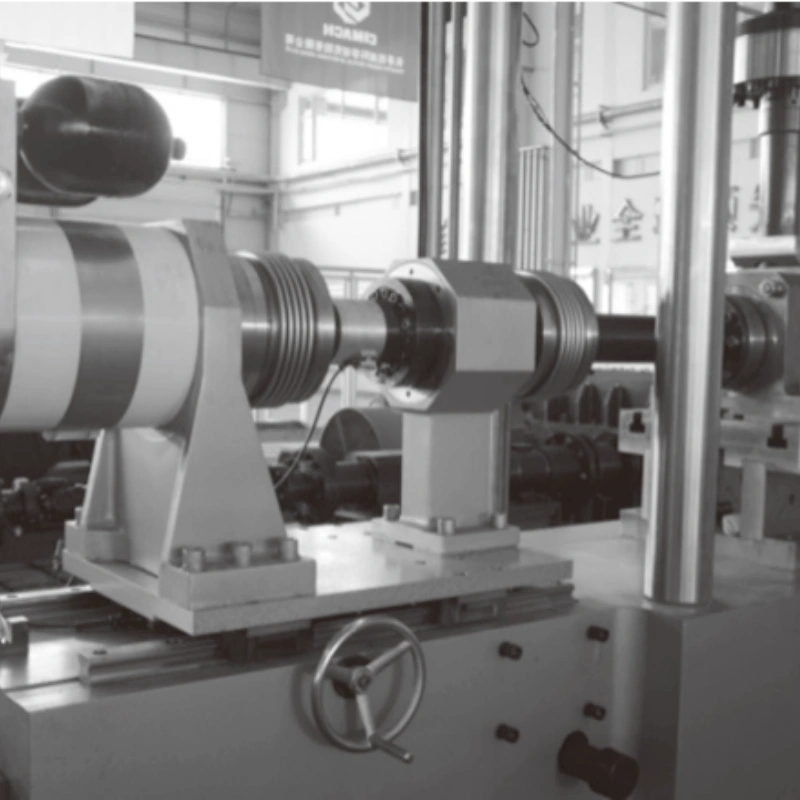

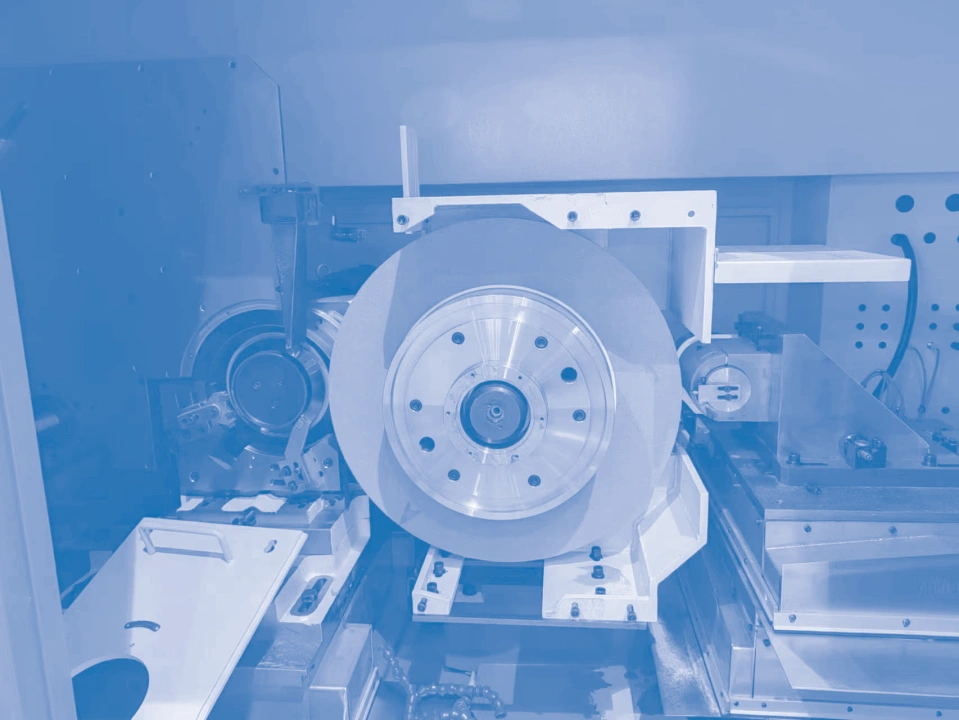

Ultra precision machine tool hydrostatic module

Through the accumulation of specialized hydrostatic machine tool component technology, we aim to upgrade and transform traditional mechanical bearing machine tools, provide various hydrostatic components for ultra precision CNC machine tools, enhance China’s independent research and development of ultra precision machining technology for machine tools, and develop a batch of internationally advanced new ultra precision intelligent manufacturing equipment.

Significant features:

- High stiffness

- High speed

- High precision

- Long lifespan

Application:

- Hydrostatic spindle

- Grinding machine

- hydrostatic electric spindle

- Lathe hydrostatic electric spindle

- CNC center hydrostatic electric spindle

- Heavy-duty working condition hydrostatic spindle

- Friction torque measurement hydrostatic spindle

- Hydrostatic guide rail

- Machine tool hydrostatic guide rail

- Other

- Machine tool hydrostatic screw

- Hydrostatic turntable

- Hydrostatic screw

- Hydrostatic screw

ACTUATOR ATTACHMENT

Seamless swivel

The seamless swivel has a spherical bearing and uses Longxi self-lubricating joint bearings. It is installed at the front and rear ends of the servo actuator to ensure the tracking of the loading direction and avoid lateral forces on the actuator, thereby extending its service life. It can adjust gap to preload.

Capacity: 25-2000KN

Feature:

- Equipped with a pre tightening adjustment mechanism, the bearing clearance can be adjusted to pre tighten.

- Rotating supports can be used for alternating loads.

- The rotation range of the support is ± 90 degrees, and the tilt angle is ± 7 degrees.

Spherical swivel

The spherical swivel adopts a spherical structure and is equipped with an annular lubricating oil groove. It is installed at the front and rear ends of the servo actuator to ensure the follow-up of the loading direction and avoid lateral force on the actuator, thus extending its service life.

Capacity: 25-630KN

Feature:

- It has the characteristics of low friction, high dynamic characteristics, high resistance to alternating loads, and long service life.

- Equipped with a pre tightening adjustment mechanism, the gap between alternating loads can be adjusted.

- Rotation angle: ± 10 °, the shaft can rotate 360 °.

The History of Hydraulic Transmission

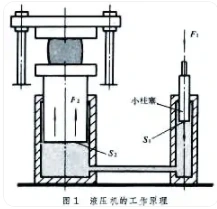

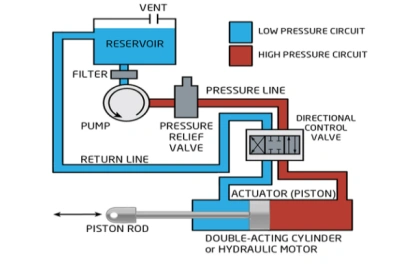

Hydraulic transmission, a transmission method that uses liquid as the working medium and converts energy through liquid pressure.

It has a profound historical background. Since the late 18th century when Britain successfully manufactured the world’s first hydraulic press, hydraulic transmission technology has undergone over two hundred years of development and evolution. Although it was born early on, the true widespread application of hydraulic transmission technology was not achieved until the 1930s.

Hydraulic transmission originated in the 17th century, but it was not widely used until the 1930s. Early key developments included Pascal’s principle of hydrostatic transmission and Brahman’s first hydraulic press. In 1650, Pascal proposed the principle of hydrostatic transmission, which revealed that in a closed container, when a static liquid is subjected to pressure at one point, the pressure will be uniformly transmitted to all points of the connected vessel. In 1795, Joseph Bramah of England applied this principle to industrial practice and successfully manufactured the world’s first hydraulic press using water as the working medium, marking the birth of hydraulic transmission technology. Subsequently, in 1905, the working medium was changed from water to oil, which further improved the effectiveness of hydraulic transmission

The application of hydraulic technology in weapons during World War II improved technical performance and quickly entered the civilian field after the war. In conjunction with industry standardization development, it was widely used in multiple fields. During World War II, the application of hydraulic transmission and control devices in weapons significantly improved their performance and also promoted the rapid development of hydraulic technology. After the war, hydraulic technology quickly shifted from the military field to civilian use, and with the continuous improvement of industry standards and the standardization, normalization, and serialization of components, it gradually gained widespread application in fields such as mechanical manufacturing, engineering machinery, agricultural machinery, and automobile manufacturing. After the 1960s, with the vigorous development of atomic energy technology, space technology, computer technology, microelectronics technology, etc., hydraulic technology once again made significant breakthroughs and became an important pillar for automated production and improving labor productivity in various fields of the national economy.

Hydraulic transmission has good lubrication, flexible liquid delivery, excellent speed regulation performance, and high transmission stability. The hydraulic transmission system consists of five core parts: power components, actuating components, control and regulation components, auxiliary components, and working medium. Compared with mechanical transmission, hydraulic transmission exhibits many significant advantages: firstly, due to the usual use of oil as the transmission medium, hydraulic components can obtain good lubrication; Secondly, the working fluid can be flexibly transported to any position through pipelines, allowing hydraulic actuators and hydraulic pumps to maintain a relatively long distance; In addition, hydraulic transmission can easily convert the rotational motion of the prime mover into linear motion.

Hydraulic transmission also has excellent speed regulation performance, which can achieve a wide range of stepless speed regulation during operation, with a transmission ratio of up to 1:1000, and is not limited by power size. Meanwhile, it is also easy to implement load control, speed control, and direction control, supporting centralized control, remote control, and automatic control. Hydraulic transmission is smooth and seamless, with effortless operation and quick response, capable of high-speed starting and frequent reversing. Finally, the standardization, serialization, and universality of hydraulic components make design, manufacturing, and application more convenient.

The important actuator of the electro-hydraulic servo fatigue testing machine is the linear actuator, which has gone through three stages of development: sealing ring, gap seal, and hydrostatic bearing seal. At present, all three types of linear actuators are within the scope of market promotion and use.

From cost to service life, each actuator has corresponding performance indicators and parameters. Each one has its own practice.

Hydrostatic linear servo actuators have faster frequency response during operation, better performance in resisting lateral forces, lower friction coefficient, and support for higher response frequencies. It is an actuator that supports high speed, high operation, and long lifespan.