Горные породы и геомеханика

ГЛАВНАЯ>>Испытательная установка>>Rock & Geomechanics

Горные породы и геомеханика

Основная экспериментальная ценность таких материалов, как горные породы и грунт, бетон и асфальт, заключается в обеспечении научной основы для инженерной безопасности, экономичности и долговечности, а также в предотвращении инженерных аварий или пустой траты ресурсов, вызванных неясными свойствами материалов.

Соответствующие испытания имеют важное значение: ① Обеспечение инженерной безопасности: предотвращение рисков, исходящих от источника; ② Оптимизация затрат на инвестиции: ③ Достижение максимальной экономической эффективности; Содействие технологическим инновациям: адаптация к сложным инженерным требованиям.

ДОСТУПНЫЕ МОДЕЛИ

Одноосный испытательный стенд

Испытательная установка на двуосное и сдвиговое растяжение

Трехосная испытательная установка для горных пород

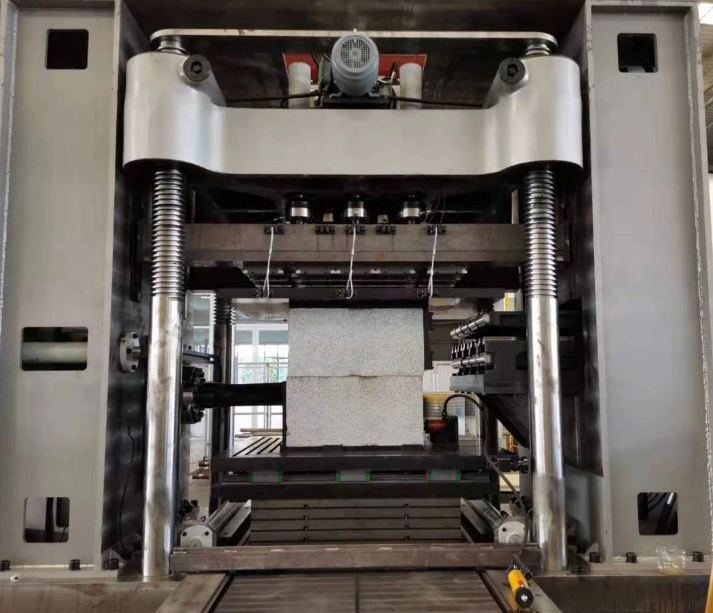

Одноосный испытательный стенд

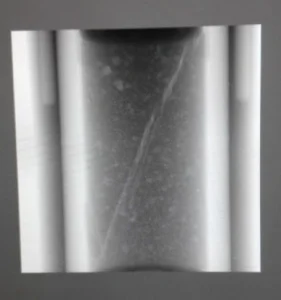

It is mainly used to study the physical and mechanical properties of materials such as rock, geotechnical materials, concrete, and asphalt pavement. It can conduct uniaxial static compressive strength and deformation tests, uniaxial static tensile strength and deformation tests, uniaxial dynamic fatigue tests, uniaxial dynamic modulus tests, uniaxial full-curve tests, ultrasonic tests, acoustic emission tests, and ultrasonic wave velocity anisotropy tests.

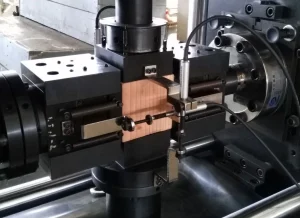

Испытательная установка на двуосное и сдвиговое растяжение

The rock shearing testing rig is mainly used for shear (fracture) resistance tests of materials and interfaces such as sand and gravel, rock itself, concrete itself, concrete-rock interfaces, and weak structural planes of rock masses. This system can apply normal and tangential loads, with the two directions being loadable independently or synchronously.

It can conduct tests including uniaxial static compressive strength and deformation tests, uniaxial static tensile strength and deformation tests (direct tension/indirect tension), uniaxial dynamic fatigue tests, uniaxial dynamic modulus tests, rock direct shear strength tests, rock biaxial direct shear strength tests, rock direct shear creep tests, rock dynamic shear tests, and rock dynamic biaxial shear tests.

Technical Parameters

- Maximum Normal Load: 2000kN

- Maximum Tangential Load: 3000kN

- Normal Dynamic Loading Frequency: 5Hz

- Normal Dynamic Loading Frequency: 20Hz

- Normal Loading Rate: 200mm/min

- Tangential Loading Rate: 100mm/min

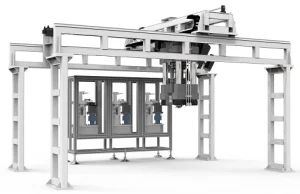

The biaxial creep testing rig is mainly used for creep tests, shear tests, and stress relaxation tests of materials such as rock and concrete under biaxial compression conditions. It can simultaneously measure the biaxial bilateral deformation values of specimens and can be controlled by force or deformation.

Main Functions and Features

- The force loading adopts electric servo loading technology with a high transmission ratio, featuring higher precision and more stable long-term load holding.

- A large reduction ratio transmission method is used to ensure the stability of ultra-slow loading.

- The adopted roller row anti-friction device reduces direct mutual interference between normal and tangential forces, making force measurement more accurate.

Трехосная испытательная установка для горных пород

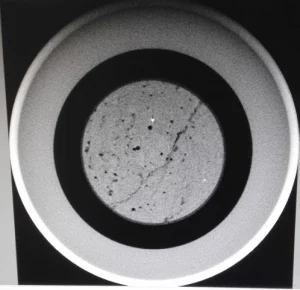

It is mainly used to study the physical and mechanical properties of materials such as rock, geotechnical materials, concrete, and asphalt pavement under triaxial stress conditions. Built on a single control platform, this system is integrated with components of different functions. It can perform tests including triaxial static compressive strength and deformation tests, triaxial static tensile strength and deformation tests, shear tests, triaxial creep tests, triaxial rheological tests, triaxial high-low temperature and high-pressure tests, rock core resistivity tests, triaxial gas/liquid seepage tests, triaxial hydraulic fracturing tests, triaxial acoustic emission tests, triaxial ultrasonic tests, triaxial CT scanning tests, and triaxial displacement (oil/water) tests.

The true triaxial test system is a specialized test system developed based on electro-hydraulic servo technology. It can apply principal stresses in three directions to materials such as rock, geotechnical materials, concrete, and asphalt pavement. With the three directions capable of loading independently or synchronously, the system can conduct tests including triaxial static compressive strength and deformation tests, triaxial static tensile strength and deformation tests, true triaxial shear tests, triaxial creep tests, triaxial rheological tests, triaxial high-low temperature and high-pressure tests, triaxial gas/liquid seepage tests, triaxial hydraulic fracturing tests, triaxial acoustic emission tests, and triaxial ultrasonic tests.

- High-temperature & High-pressure coupled True triaxial testing rig

It can simulate a geothermal temperature of 600°C with an axial pressure of 4500 kN.

- STSA Multi-Field Coupling Testing Rig

Stress/Temperature/Seepage/Acoustic Multi-Field Coupling Testing Rig: Axial pressure 15000kN; Temp range: -60~+600℃; Seepage media: oil, water, CO2, N2, NH4

- Hydraulic fracturingtesting rig

Axial pressure: 3000kN; Fracture pressure: 80MPa

- Soft rocktesting rig

- Stress Freezing testing rig

- Refractory bricktesting rig

03 Dynamic Triaxial Testing Rig for Pavement Asphalt Materials.

It applies dynamic loads to pavement materials such as asphalt mixtures and cement concrete. It tests the mechanical properties of pavement materials under triaxial loading conditions, and can perform dynamic cyclic loading tests, fatigue tests, uniaxial tension tests, uniaxial compression tests, high-low temperature confining pressure triaxial tests, high-low temperature true triaxial tests, stress path tests, and custom stress path tests, as well as simulate various complex working conditions.

Функции:

- Load: 200kN

- Tensile test load: 50kN

- Dynamic loading frequency: 0~25Hz

- Temp range: -35~+80℃

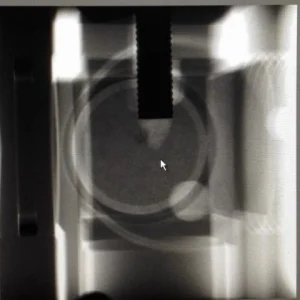

Mainly used to study the physical properties of rock materials under triaxial static loading, that is, to use CT imaging technology to reproduce the internal damage evolution process of rocks, analyze the generation and extension of internal cracks, etc.

Функции:

- Sample size: Φ25-Φ40mm, 25-60mm3

- Axial compression test pressure range: 10MPa~500MPa

- Horizontal test force range: 10MPa~100MPa

- Deformation measurement range: ≥ 3mm

It is mainly used for testing the rheological properties of soil mass under triaxial stress conditions. It can perform constant load and constant deformation control under constant confining pressure. It can also apply dynamic loads with specific frequency and amplitude variations after a period of constant load or constant deformation control. It is capable of measuring the force or deformation changes of the specimen under the aforementioned triaxial loading conditions, as well as the pore pressure and pore water flow rate inside the specimen.

Функции:

- Sample size: 39.1-300mm

- Sample type: soil, coarse-grained soil, etc

- Range of axial compression test force for each head: 10kN~100kN

- Axial compression test force dynamic test frequency: 0.01Hz~0.1Hz

- Dynamic force test waveforms: triangular wave, trapezoidal wave, cosine wave;

- Range of confining pressure: 0.2~2MPa

- Deformation: Axial 0~20mm, radial (diameter) ≥ 2.5mm

- Maximum pore pressure: 2MPa

- Pore water flow rate: 0.01~20mL/min