Анализатор элементов

Анализатор элементов

Атомно-абсорбционный спектрофотометр | Анализатор ртути |

Автоматический робот для разложения графита

ГЛАВНАЯ>>Анализатор элементов>>Carbon and sulphur analyser

CS3500 Carbon and sulphur analyser

The CS3500 carbon and sulphur analyser uses high frequency heating and infrared detection principle, combined with the latest combustion and full range detection technology. It is widely used in steel, powder metallurgy, non-ferrous, magnetic materials, new energy, third-party testing, research institutes and other industries. It can simultaneously and rapidly analyse carbon and sulphur in steel and its alloys, non-ferrous metals, powder metallurgy, rare earths, NdFeB, ores and other The technology can be used to analyse carbon and sulphur in solid materials.

ДОСТУПНЫЕ МОДЕЛИ

Подробная техническая спецификация

CS 3500 Series Analyzer is ideal to provide pricise and quick determination of carbon and sulfur simultaneously in primary steels, ores, finished metals, ceramics, and other inorganic materials.

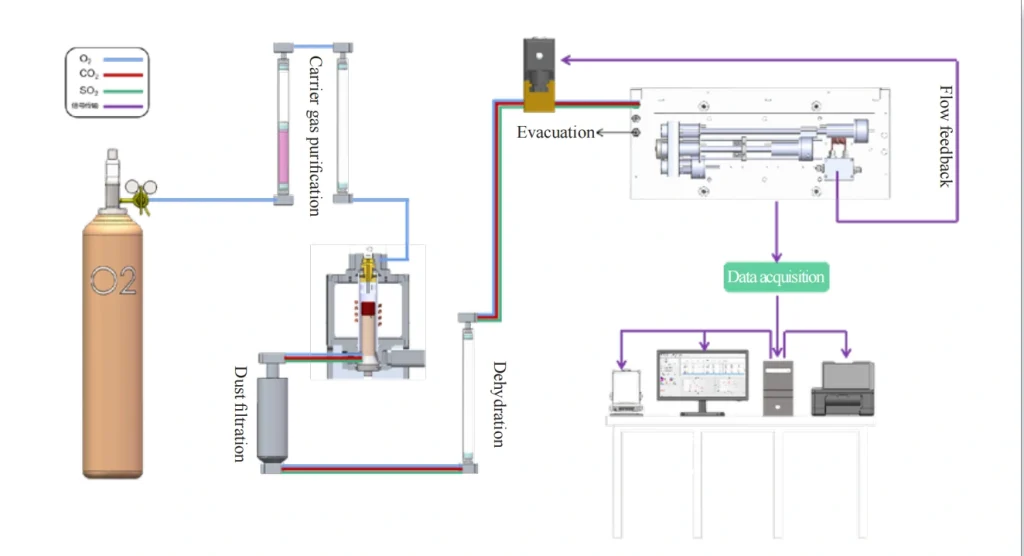

A sample of typically 0.5 to 1.0g is weight into a crucible together with 1.5g of tungsten accelerator. This crucible is placed on a pedestal which drives it into an induction furnace by a pneumatic system. The sample is completely burned in the furnace by pure Oxygen.The Carbon of this sample is oxidized to CO2 and the Sulphur content to SO2. Dust and other particles are trapped in a filter system.The CO2 and SO2 is transported from the furnace in the Oxygen carrier gas to the infrared adsorption detectors.The actual gas concentrations are determined and the data are send to the PC.The operation software is calculating the results after integration of the whole signal peaks. A calibration with known samples builds up a database which created the necessary accuracy and precision. The burned crucible is driven out of the furnace by the pneumatic system and disposed by an operator. The furnace and gas flow system is purged after analysis by clean Oxygen to avoid any interference (memory effect) of the individual samples.

Analysis range (500mg sample):

Low carbon: 1ppm ~ 0.1% high carbon: 0.1% ~ 5%

Low sulfur: 1ppm-0.3% high sulfur (150mg sample): 0.3% – 30%*

Note:

The analysis range can be extended to 100% by changing the sample weight.

High sulfur absorption tank can be customized according to customer demand.

Analysis accuracy:

Low carbon: 1ppm or RSD ≤ 1% high carbon: RSD ≤ 0.5%

Low sulfur: 1.5ppm or RSD ≤ 1.5%, high sulfur: RSD ≤ 1.5%

Sensitivity:

0.01ppm

Analysis time:

30 s ~ 40 s

Sample weighing:

The recommended range is 0.1g-0.5g, and the sample weight can be changed according to the sample content.

High frequency induction furnace :

18mhz 2.7kva

Power supply :

220 VAC ± 10% 50 ± 1 Hz, minimum current 16 A

Instrument size :

55cm in width, 77cm in height and 76cm in thickness

Weight:

100kg

Carrier gas:

oxygen, purity 99.9%

The induction furnace ensures a fast and complete combustion at temperatures of about 2200°C. It’s robust design ensures a long lifetime and minimized maintenance. With 18.5 MHz and 2.2 kVA its a suitable furnace for the combustion of a wide range of materials.

The unique design reduces a splattern and the dust from the combustion is trapped in an easy to clean metal filter.

The specialty for this application developed IR detector with up to 4 independent absorption units ensures the needed wide analytical range with high precision.The reliable design is known for long term stability and very low maintenance.

High tech detectors and interference filters are the base for a long time stability of the calibration. A build in temperature controller makes the detector system independent from the environmental conditions.

Solid-state pyroelectric detector made in Germany

◆ Flexible heating power control

◆ Advanced temperature control technology

◆ Advanced gas flow control technology

◆ Software has unique features

◆ IR signal data processing result is ace after linearizing

◆ Analytical precision reached international advance level

◆ Electric parts with high reliability

◆ Rich in diagnosis function

◆ Redundancy protection against meltdown

◆ Sealed gas passage with no dead volume

▪CIF

▪Упаковка: Деревянный ящик