Element Analyzer

Element Analyzer

Atomic Absorption Spectrophotometer | Mercury Analyzer |

Automatic Graphite Digestion Robot

Home>>Element Analyzer>>Oxygen/Nitrogen/Hydrogen Analyzer

ONH3500 Oxygen/Nitrogen/Hydrogen Analyzer

The ONH3500 Oxygen/Nitrogen/Hydrogen Analyzer is used for oxygen, nitrogen and hydrogen determination in ferrous and non-ferrous metals, rare earth materials, alloys, and some other inorganic materials.

AVAILABLE MODELS

Detailed Technical Specification

A graphite crucible is placed on the holder and the impulse furnace is closed by the pneumatic system.The sample of typically 1g is dropped into the loading mechanism after weighing. The outgassing phase starts the analysis cycle to clean the furnace from Oxygen and Nitrogen out of the air.The sample loading mechanism release the sample into the now cleaned crucible.The oxygen content of the sample react with the Carbon from the graphite crucible to CO and the Nitrogen content to elemental N2 gas at temperatures of about 2200°C. Both gases were transported by the Helium carrier gas to the oxidation furnace where Copper Oxide converts the CO to CO2. This CO2 concentration is analysed by an infrared absorption detector and the Oxygen concentration is calculated.The Nitrogen is analysed afterwards by a thermal conductivity detector.

- Range: Oxygen:

Low Oxygen: 0.1ppm ~ 0.5%*; High Oxygen: 0.5% ~ 20%*

Nitrogen: Low Nitrogen: 0.1ppm ~ 0.5%*; High Nitrogen: 0.5% ~ 50%*

Hydrogen : Low Hydrogen: 0.1ppm ~ 200ppm* ; High Hydrogen: 200ppm ~ 5000ppm*

Note: * the measurement range can be changed by changing the measurement quantity. - Sensitivity: Oxygen ,Nitrogen and Hydrogen:0.01ppm

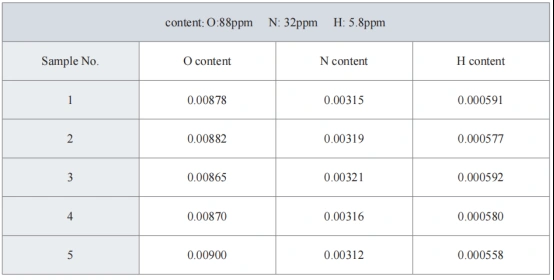

- Repeatability: Oxygen and Nitrogen:1ppm or ≤1%; Hydrogen: 0.2ppm or ≤2%

- Sample mass: 1g (Sample mass can be changed according to the content)

- 5.Analysis time: about 3 min

- Carrier gas: High purity helium for O/N, high purity nitrogen for H

- Pneumatic gas: Nitrogen, industrial grade

- Structure: Modular Structure, including analyzer, computer, electronic balance*, printer*, water circulate chillers*. Note: * is optional.

- Detection system: Solid state Infrared detector is used for Oxygen. Thermo-conductivity detector is used for Nitrogen & Hydrogen.

Infrared Cells: Two IR cells are installed in the analyzer. The length of each cell can be customized according to the content of samples .

Detector: Solid-state pyroelectric detector made in Germany.

Motor: Synchronous motor made in Swiss.

Source:Anti-oxide, stable IR emitter made in US.

Temperature control: Keep constant temperature in the whole infrared unit to make sure the temperature of detected gas to be stable and the results to be accurate.

Protecting gas: Infrared emitter and the detector are separated from the ambient by nitrogen, which can improve the stability and the accuracy.

Thermo-conductivity (TCD) detecting unit:Anti-oxide NTC thermistor

Signal processing: Small current control technique is developed to make sure the thermistors can be used without carrier gas.

Reference gas circuit: Low fow control technique is used - Gas fow control: High sensitive and accurate electric fow control technique based on the low pressure diference is applied, andAnti-Overshoot System is applied

- Pulse heating electrode furnace: Current:0-1500A, Power:8.5KVA, Temperature:Max 3500℃

- Calibration: 1) Fast calibration 2) Normal calibration

- Power: 220VAC±10%, 50±1Hz, current max. 50A(Max.10KW)

▪CIF

▪Package: Wooden case