Creep Testing Systems

R series Creep testing systems

Home>>Static Testing Systems>>Creep Testing Systems

R SERIES Creep Testing Systems

A tensile specimen under a constant load maintained at a constant temperature.

R-series Creep / Stress Rupture testing systemsare widely applied to various occasions with extraordinary performance and stability. They are especially designed for creep testing, relaxation, stress rupture, low fatigue,etc.

Typical test capacity comes from 10-100KN. Higher capacity could be customized.

Typical test temperature: 300-1200℃.

This system adopts high response low-noise electromechanical servo drive and powerful closed-loop controller to ensure the accuracy and efficiency of the test.

Application:

Creep, stress-rupture, creep-rupture, creep-fatigue, tensile creep

Test workpiece:

Metal, plastics, alloy, carbon fiber

Test standard:

ISO 204, ASTM E139, ASTM E328, ASTM E2714

AVAILABLE MODELS

3 Different models depends on your need

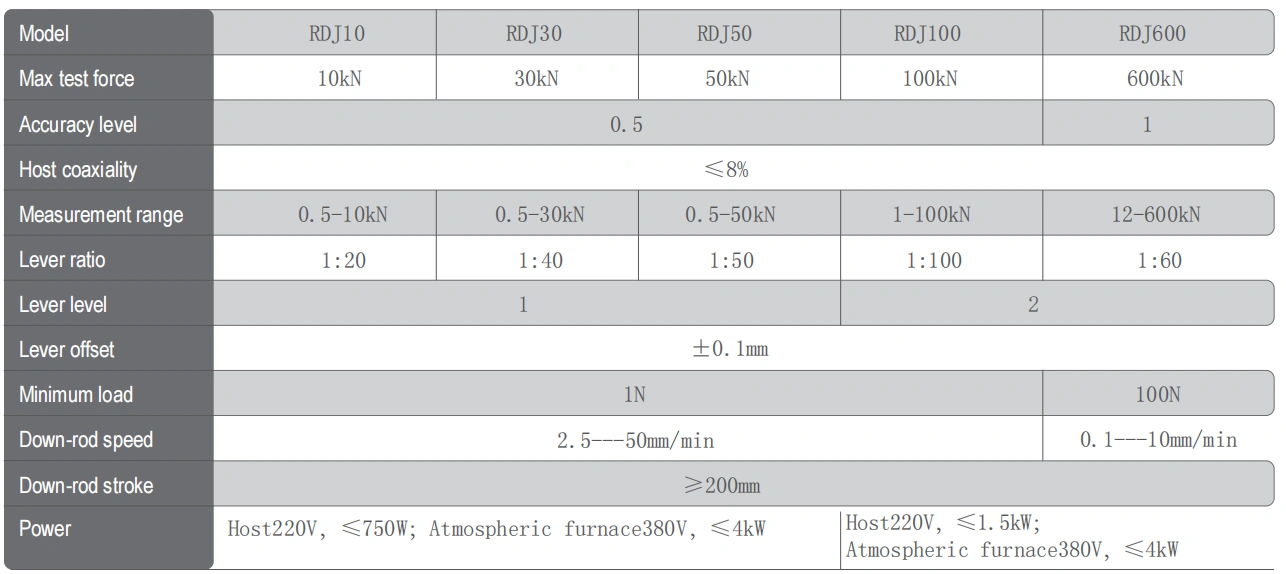

RDJ Series Mechanical Creep testing system

RDJ mechanical creep endurance testing system

▪Capacity:

RDJ-10:10kN

RDJ-30:30kN

RDJ-50:50kN

RDJ-100:100kN

▪Knife bearing structure

▪PID temperature control

▪Three stage heating

▪Break point recovery, offline test

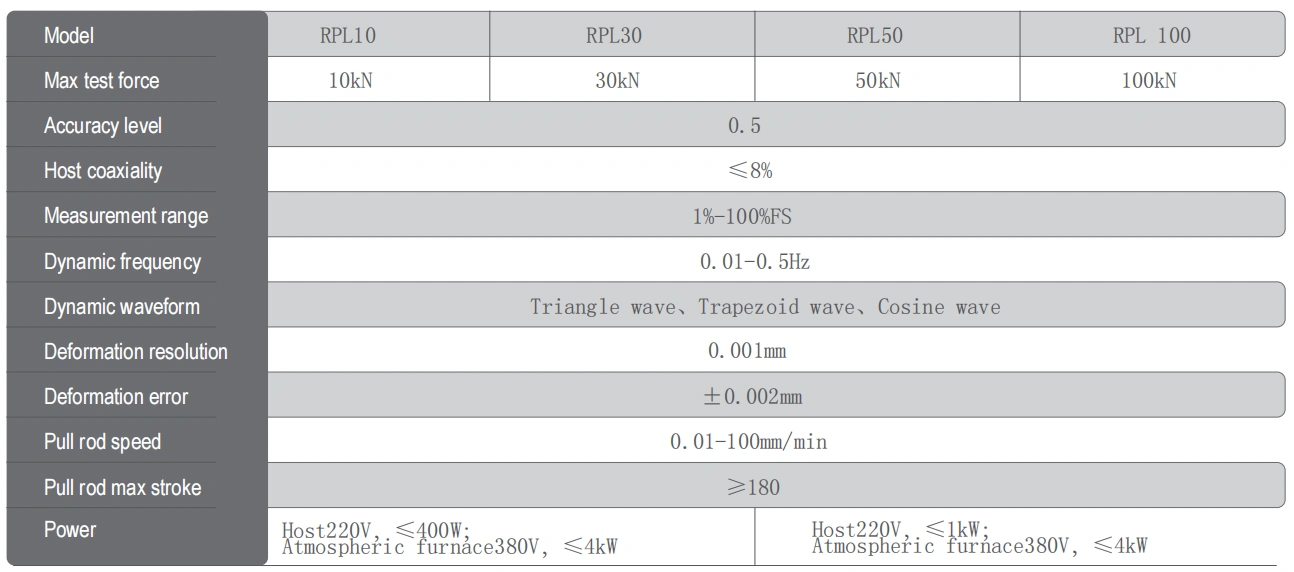

RPL Series Creep-Fatigue testing system

RPL series of high temperature electronic creep fatigue testing system

▪Capacity:

RPL-10:10kN

RPL-30:30kN

RPL-50:50kN

RPL-100:100kN

▪Electromechanical servo drive

▪PID temperature control

▪Three stage heating

▪Break point recovery, offline test

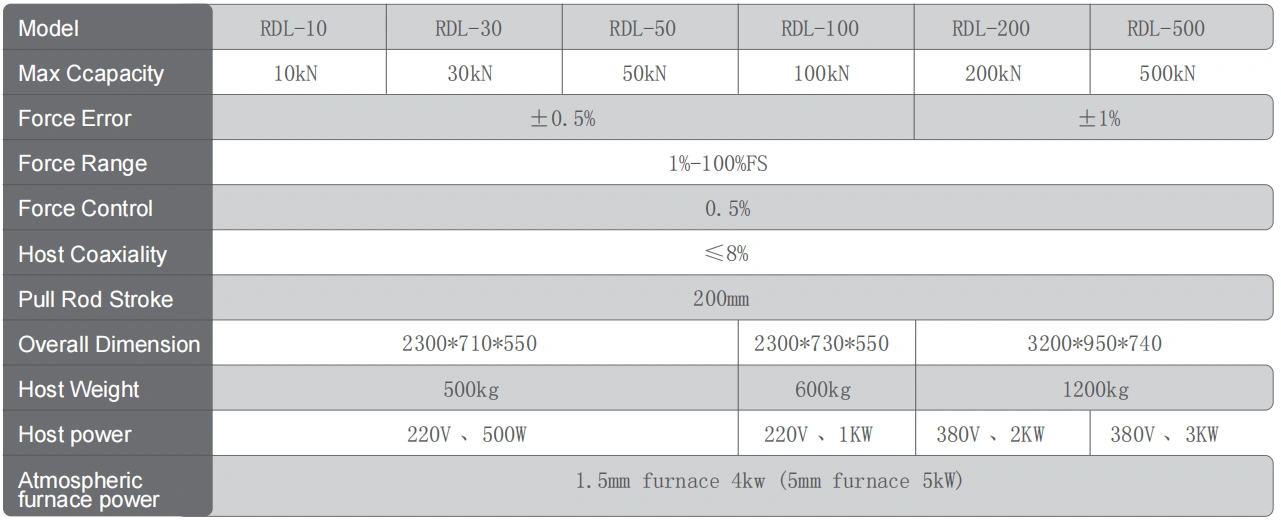

RDL Series Creep-Fatigue testing system

RDL series electronic creep durability testing system

▪Capacity:

RDL-10:10kN

RDL-30:30kN

RDL-50:50kN

RDL-100:100kN

▪Electromechanical servo drive

▪PID temperature control

▪Three stage heating

▪Break point recovery, offline test

Detailed Technical Specification

Grip/Fixture type

▪Tensile grip

▪Pull rod type

▪High Temperature Pull Rod Fixture

▪K465:950℃

▪DZ22:1050℃

▪Environmental Chamber:~350℃

▪Atmospheric Furnace:300℃~1200℃

▪Grating sensor

▪Video Extensometer

▪FOB

▪CIF

▪Package: Wooden case

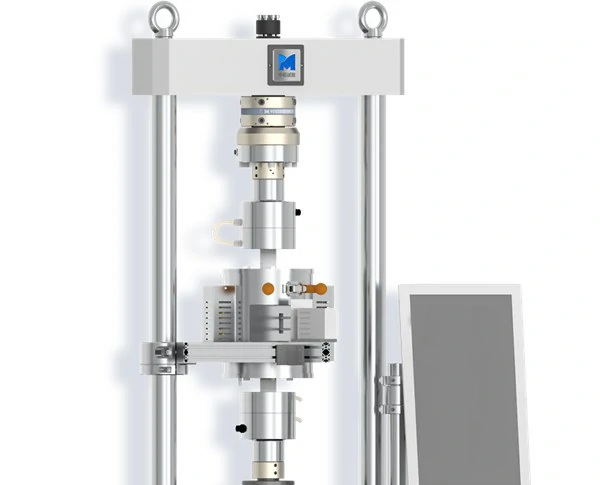

High stiff frame

Sturdy Construction

The machine is built with a robust and rigid frame, providing excellent stability and minimizing vibrations during testing.

This ensures accurate and reliable test measurements even under demanding conditions.

Precise Results

The superior frame rigidity ensures precise and repeatable measurements, allowing for reliable data analysis and evaluation of material behavior.

Easy Installation and Maintenance with Electronic

Control System

User-Friendly Setup

The R-Series Creep Testing Systems features an intuitive electronic control system, simplifying the installation process. The user-friendly interface guides users through the setup, reducing time and effort required for configuration.

Convenient Operation

With its easy-to-use interface, operators can efficiently control and monitor the testing process. The systems requires minimal adjustments after installation, enabling users to start testing quickly and conveniently.

Streamlined Maintenance

The design of the systems facilitates easy maintenance, reducing downtime. Regular maintenance tasks, such as calibration and component replacement, are straightforward and can be performed with ease.

High Precision Controll System

Reliable

Versatile Testing: The R-Series Creep Testing Systems offers multi-station capabilities, accommodating up to 5 workstations simultaneously. This allows for efficient testing of multiple samples, increasing productivity and throughput.

Collaborative Approach: Through a deep collaboration with Doli, a renowned expert in testing solutions, our machine integrates seamlessly with multi-channel systems. This partnership ensures optimal performance and synchronized operation, enhancing the overall testing experience.

Software

Reliable

Precise Control: The machine is equipped with advanced software that enables precise configuration and control of various test parameters. Users can easily set up and adjust parameters such as load, temperature, and test duration according to their specific requirements.

Real-time Monitoring: The software provides real-time monitoring and visualization of test data, including temperature measurements through thermocouples. Users can track multiple parameters simultaneously, gaining comprehensive insights into material behavior during creep testing.

Seamless Integration: The machine’s software is designed to integrate smoothly with other testing equipment and data management systems. This allows for seamless data exchange and compatibility, enhancing overall testing efficiency and data management.

Thermocouple Monitoring: Real-time thermocouple monitoring ensures accurate and continuous temperature measurement throughout the testing process. This enables precise temperature control and provides valuable insights into material performance under various temperature conditions.