Automatic Straightening Systems

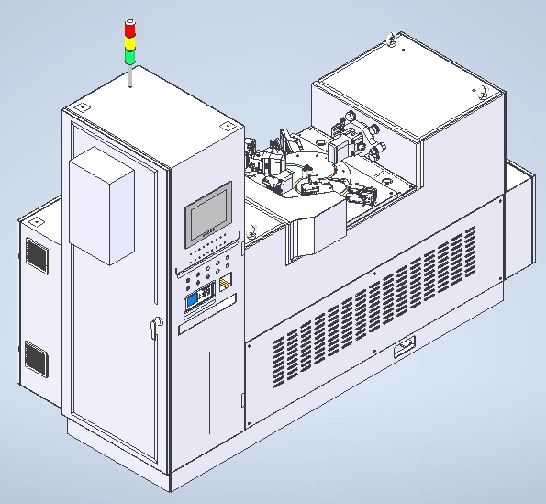

Door Type and the C-Type

Home>>Straightening machine & Balancing machine>>Automatic Straightening Systems

Automatic Straightening Systems

Automatic Straightening Systems

SINOTEST has officially started our straightening machine business since 1994.

Our automatic straightening machine are designed to correct geometric deviations of long metal products after processing – primarily thermal.

The main task of the equipment is to restore the required geometry of products by controlled application of force with precise adjustment of the impact zone. Presses allow to eliminate distortions, bends and deformations that occur during heating, welding, casting or mechanical processing.

Parameters:

- Capacity: 20kN-20000kN

- Servo loading max. capacity: 1200kN

- Single point straightening efficiency: 600pcs/hour

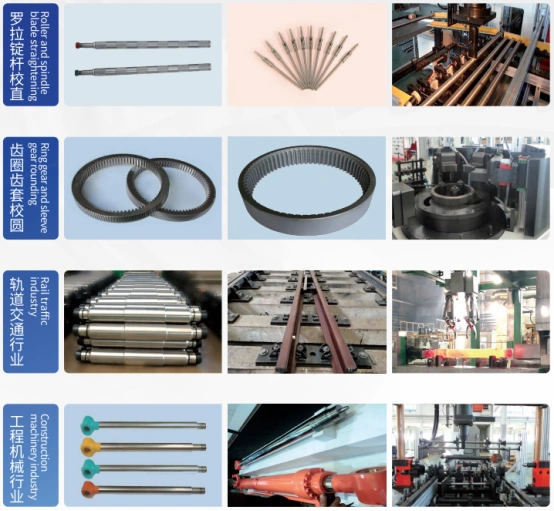

Application industry:

Textile machinery, transmission, passenger vehicle, commercial vehicle, rail traffic, electromechanical tool, military industry support, petrochemical field, construction machinery, aerospace

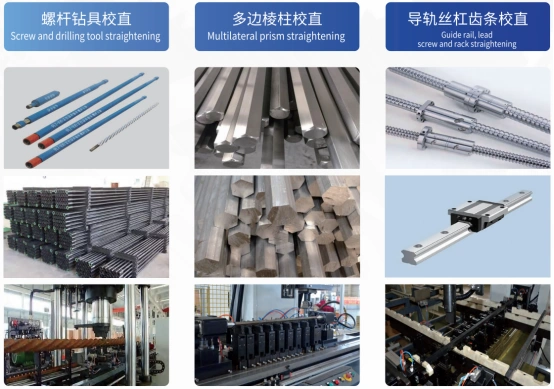

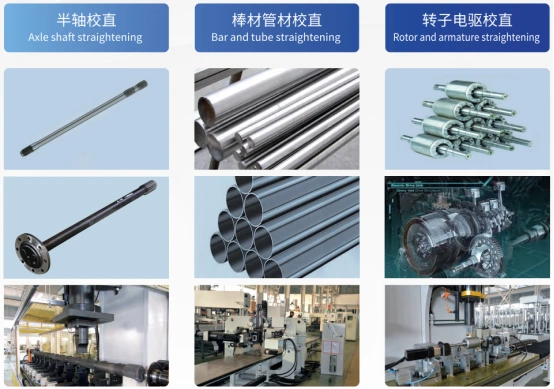

Workpiece:

Cam shaft, crank shaft, gear shaft, drive shaft, axle shaft, piston rod, drilling rod, roller, spindle, guide rail, barrel, gear ring, bearing ring, etc.

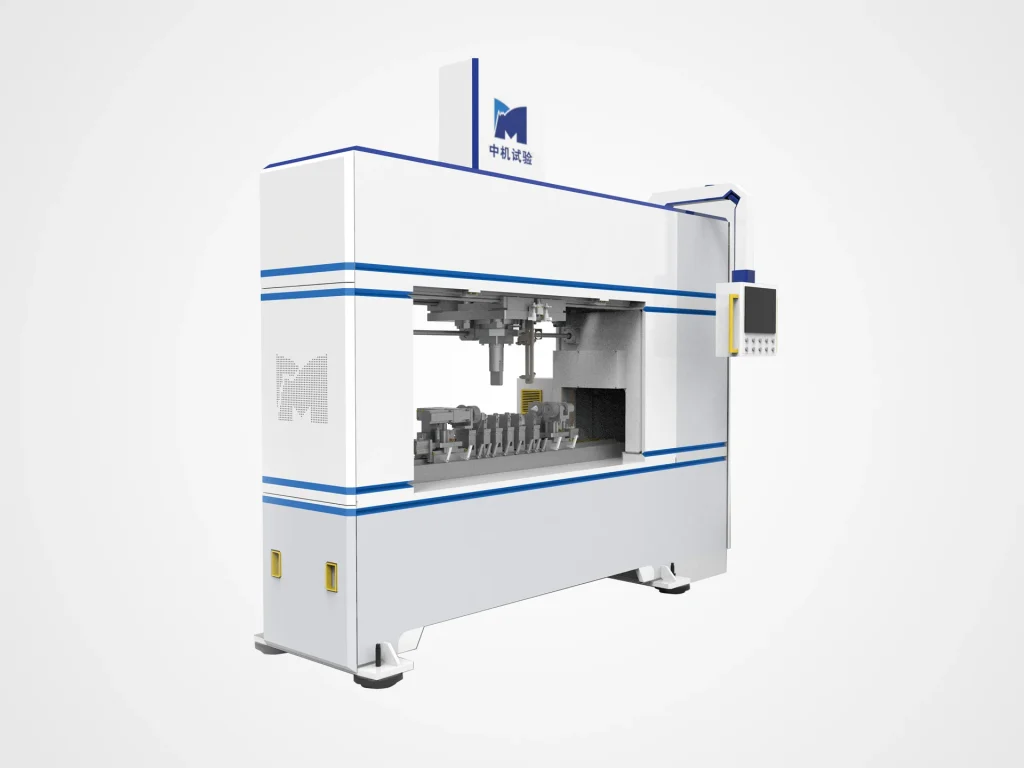

Door-type Automatic Straightening Machine

- JJM series: Mechanical loading type

- JEM series: Hydraulic loading type

- Fully automatic operation mode

- High adjustment accuracy

- Adaptability to various types of products

- Intelligent self-learning

- Remote maintenance assistance

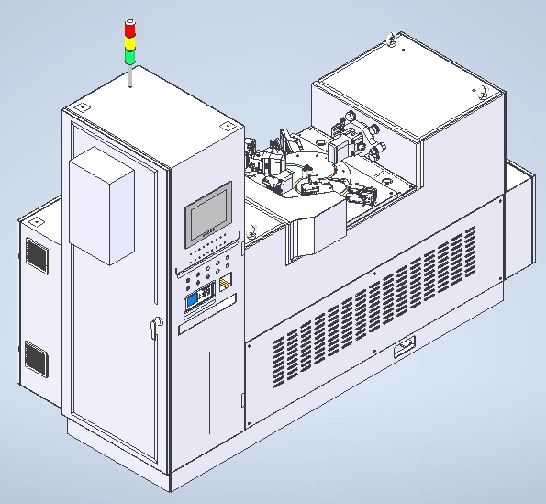

C-type Automatic Straightening Machine

- JJC series: Mechanical loading type

- JEC series: Hydraulic loading type

- Fully automatic operation mode

- High adjustment accuracy

- Adaptability to various types of products

- Intelligent self-learning

- Remote maintenance assistance

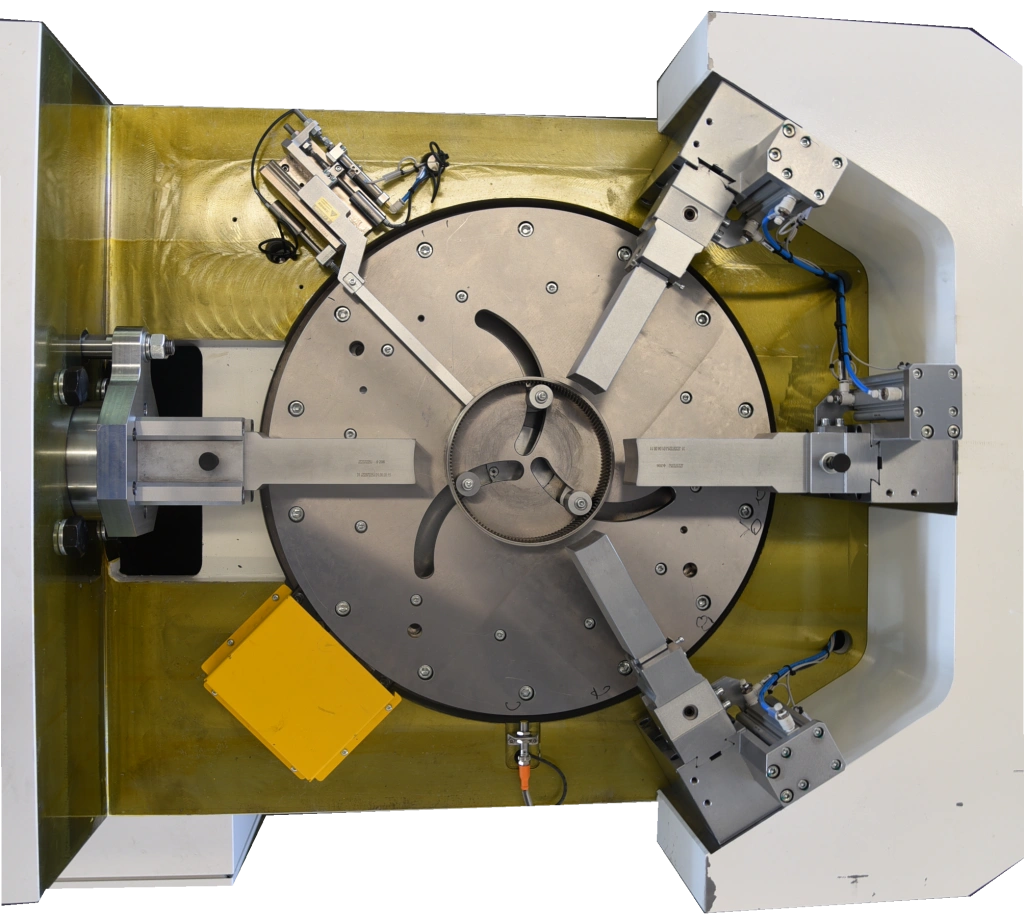

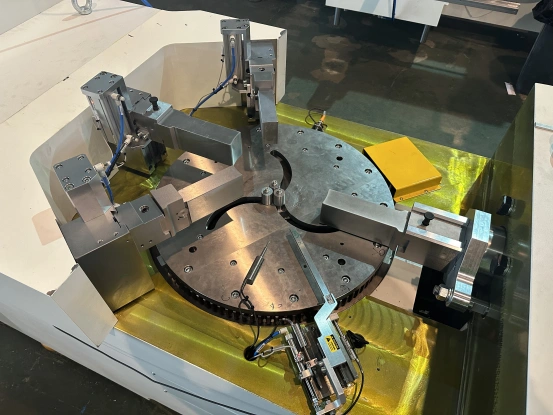

YW Series Ring Straightening Machine

- 100kN-500kN

- Mechanical loading

- Fully automatic operation mode

- High adjustment accuracy

- Measurement by rotating

- Servo Motor drive

- Intelligent self-learning

- Remote maintenance assistance

Detailed Technical Specification

▪Capacity: 20-20000kN

▪Max. Servo loading:1200kN

▪Max. Length range of the workpiece: 15000mm

▪Max. Straightening accuracy:0.015mm

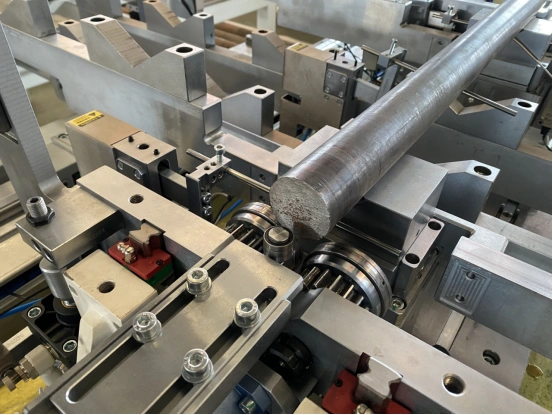

▪Roller drive

▪Center drive

▪Measurement tappet

▪Support block

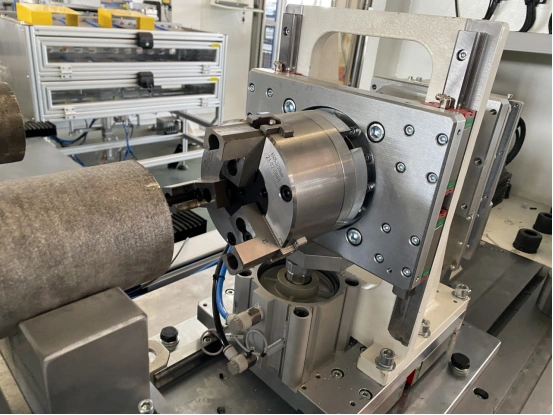

▪Indenter

▪Oil filter

▪Safety light curtain

▪Metal safety fence

▪Hole cleaning device

▪Keyence Laser Marking System

▪AE crack detection system

▪QASS Crack Detection System

▪Mechanical loading and unloading system

▪KUKA Robot

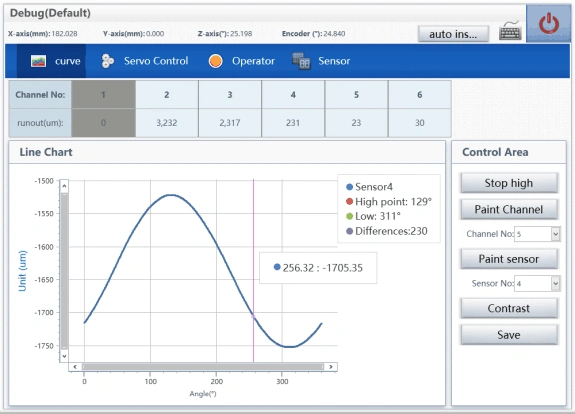

▪Intelligent algorithm for measuring the shape of parts. Before straightening, the straightening machine will automatically measure the geometric shape of the part. This algorithm distinguishes the geometric shape of the main components from surface defects, significantly improving the accuracy of determining runout. The straightening system has the function of automatically diagnosing the execution status of the straightening program, determining the locations that do not meet the standards, displaying information on the existence of non-compliance, and providing methods for eliminating non-compliance.

Floating clamping mechanism and reference part position gauge. The floating gripper uses a single gripper to complete the entire straightening process, saving time. A system equipped with two reference sensors can eliminate component installation errors caused by tool clearances.

▪Crack detection system: It can detect the occurrence of cracks in parts during the straightening process in real time. The shaft straightening machine can integrate an artificial intelligence crack detection system with independent intellectual property rights, and can also be integrated with third-party crack detection products such as AE from Japan and QASS from Germany. The crack detection system can monitor the occurrence of internal cracks in the workpiece in real time during the straightening process, and combine with the straightening machine control system to detect workpieces with cracks.

▪Equipment acceptance and part straightening process debugging. Equipment acceptance is divided into two stages: factory acceptance and subsequent on-site operation acceptance. In the first stage, the customer should send representative parts (at least 10 pieces of each type) to the production site for acceptance within the agreed time with the supplier to confirm the quality indicators. The customer shall bear the cost of delivering representative parts on their own. In the second stage, after completing installation supervision and debugging work, the quality indicators of the equipment will be confirmed on the subsequent operation site. The customer provides 50 representative parts for straightening and certification. Supplier representatives will provide technical and methodological support to ensure that the process meets stability and repeatability indicators.

The all-new V8 software is a new CIS intelligent calibration system with functions such as dynamic programming, stable interaction, intelligent algorithms, optimal strategies, real-time monitoring, intelligent diagnosis, remote control, MES system, etc.

CIS V8 ring straightening machine software

▪FOB

▪CIF

▪Package: Wooden case

Door-type Systems

Your all-round straightener

Advantages

When replacing the straightening point, the workpiece does not move, and the indenter moves along the axis of the workpiece, with small moving quality and accurate positioning;

The tooling on the platform is static, which is convenient for arranging tooling cables and gas pipes;

As the workpiece is stationary and the press head moves, the transverse dimension of the host is smaller than that of the worktable mobile straightener;

It is convenient to arrange through type feeding system and save the straightening auxiliary time.

Applications:

Suitable for shaft, step shaft, transmission shaft, gear shaft, spline shaft, crankshaft, camshaft, screw, steering gear rack, lead screw, roller shaft, half shaft, etc.

Technology

Shafts,Slender rods, Rings, Non-circular section, Thin-walled workpiece, High temperature, etc.

Key technology

Error separation,Relative measurement, Parameter self-learning and self-adaptation,Strategy adaptation,Tooling self-adjustment, remote Assistance,Real-time compensation for wear,Anti-rebound, S-bend and twisted bend straightening

Laser Measurement Technology

Laser straightness measurement

C-type Systems

Advantages

The C-type host is open on three sides, which can straighten the workpiece with a large length range, and is convenient for manual loading and unloading large workpieces, suitable for layout and adjustment of straightening fixture, and easy for operator observation;

Direct bearing, it can design for large capacity;

The distribution board can be arranged behind the C-type host, which forms compact structure and saves floor area.

Applications:

Suitable for shaft, step shaft, transmission shaft, gear shaft, spline shaft, crankshaft, camshaft, screw, steering gear rack, lead screw, roller shaft, half shaft, etc.

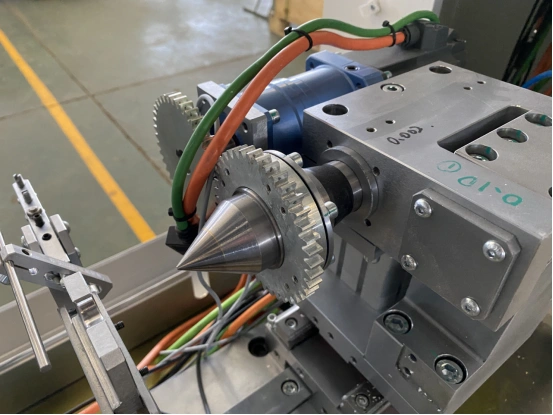

YW Series Ring Straightening Machine

The YW series ring straightening machine is able to measure and correct circular components like synchronous ring, motor ring, bearing, and gear ring.

Precise control, no need for external equipment (offline detection), avoiding production downtime.

Display resolution: 0.001mm; Storage of workpiece setting: 100 types (expandable according to user needs); Typical speed: 60 pieces/hour.

Why our machine adopts a horizontal structure

It can eliminate errors in ellipticity, triangles, and quadrilaterals, and achieve measurement and roundness correction. Apply pressure to the circular ring through a U-shaped indenter to complete straightening process. The vertical axis rotating worktable and all-round top entry mode enable easy workpiece loading and unloading.