The strength testing and fatigue testing of railway system

Home>>Testing Rig>>Rail system

The strength testing and fatigue testing of railway system

The strength testing and fatigue testing of railway system components are the core components of railway system safety, and these two tests are the key to ensuring the long-term stable operation of trains. The strength testing of railway system components aims to verify whether they can withstand extreme loads, while fatigue testing focuses on the durability of components under long-term repeated loads, which together form the basis of component safety assessment.

SINOTEST provides stable and reliable testing rigs for Rail system, brings users with a secure and efficient testing system.

AVAILABLE MODELS

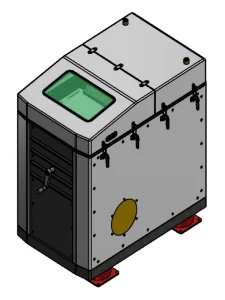

Rail Components Testing Rig

The testing rig for Orbit components includes testing railway fastening systems, rails, spring bars, etc;

Bogie Frame Testing Rig

The main test objects of the Bogie Frame testing rig are: air springs, bogies, couplings, wheelsets, rubber joints, wheel hub bearings, etc.

Rail Components Testing Rig

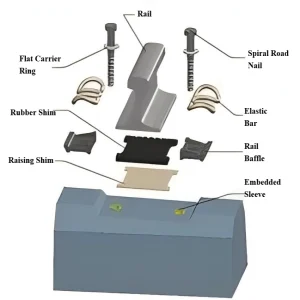

Railway fasteners are parts used on the orbit to connect rails and sleepers (or other types of sub rail foundations), also known as intermediate connecting parts. Its function is to fix the steel rail on the sleeper, maintain the track gauge, and prevent the longitudinal and transverse movement of the steel rail relative to the sleeper The railway rail fastening system is divided into: spring clip fastening system, buckle plate fastening system, and spring bar fastening system.

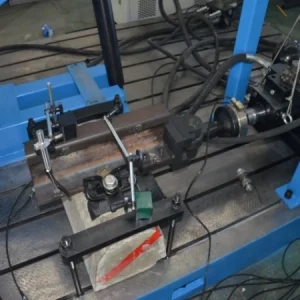

The Rail fatigue testing rig generally consists of a four column frame, a working platform, a vertical loading mechanism, a longitudinal loading mechanism, a transverse loading mechanism, etc. The main purpose is to test the fatigue performance of steel rails under complex stress states during turning.

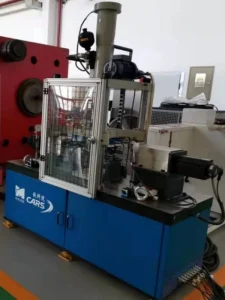

The fatigue testing rig for elastic bars is driven by a motor as the power source, which drives the polygon to rotate through a transmission mechanism, generating high-frequency vibration on the vibration plate and loading the spring bars. The maximum frequency of loading can reach 1000Hz, with a maximum amplitude of 0.05mm, and the amplitude and frequency of the test can be adjusted. Realize fatigue life testing of spring bars in a short period of time.

Bogie Frame Testing Rig

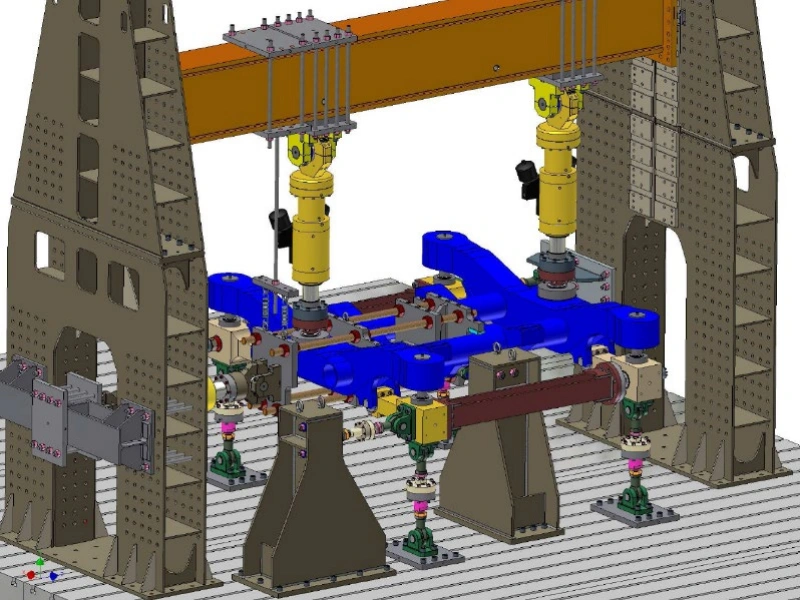

The bogie test system generally consists of a gantry composite frame, iron floor, hydraulic system, vertical loading cylinder, horizontal loading cylinder, tooling, and control system, etc. It can complete the static strength test and fatigue test of the bogie.