Pressure resistant & burst testing machine

Home >> non-metallic-testing-machines>>Pressure resistant & burst testing machine

Pressure resistant & burst testing machine

The pipe pressure resistant & burst testing machine is suitable for determining the instantaneous hydraulic burst performance and long-term constant pressure resistance of various fluid transport plastic pipes. It is an essential testing instrument for research institutes, quality inspection departments, and pipe manufacturers.

Standard: ASTM D1598-2004, ASTMD1599, ISO1167, ISO13479, ISO9080

Pressure: 0.4-10MPa

Channel: 3;6;9

Diameter: φ10-φ1200mm

- Two-Level Monitoring

Level 1: 1-hour detailed monitoring; Level 2: Comprehensive monitoring throughout the entire process. Equipped with a computer and printer, it features leakage detection, rupture identification, real-time monitoring, power-off pressure maintenance, power-off data saving, power-on data recovery, printing and storing test results, and automatic calculation of pressure formulas. The time curve display synchronizes with the actual test time, and an alarm device will sound and stop operation at that station if the test sample shows abnormal leakage or if the pressure or water temperature fails to meet the set requirements, without affecting other stations.

- Multi-Functional Functionality

It can perform long-term hydro-pressure testing of pipelines, as well as burst testing of pipes (each channel can perform burst and pressure tests). It can also be used for thermal stability testing of thermoplastic pipes under hydro-pressure conditions. The first channel features dual solenoid valve pressure compensation, enabling burst testing of pipes up to 200mm in diameter. Each channel of the testing machine has multi-stage energy storage pressure control, ensuring fast response and stable pressure control, and extending the service life of the solenoid valves.

- Dual-Pipe Circuit Structure

Traditional pipe hydro-pressure testing machines supply pressure to a pressure-replenishing valve, which then transmits the pressure to the sample via pressure acquisition. The other end is connected to a pressure relief valve, resulting in no backflow and pressure difference between the sample and the sensor. Therefore, our product adopts a new design: the pressure control system uses a dual-pipe circuit structure with independent pressure supply and pressure acquisition. That is, the pressure unit and the sample are connected by two pipes. One pipe is a pressure-replenishing pipe, used for pressure replenishment and relief, and the other pipe is used to test the sample pressure, which is directly taken from the sample inlet.

- Superior Quality

The entire machine uses EU CE-certified electronic components, German solenoid valves, and GEMS sensors; ensuring extremely high reliability and stability during long-term operation. It offers high efficiency with multiple testing stations per line, low operating costs, and excellent economic benefits.

- Wide Pressure Control Range

The pressure control range for each station is arbitrarily set from 0.4-25MPa.

- Guaranteed High Reliability

All electrical, mechanical, and software components are equipped with safety protection measures, such as protection against leakage, short circuits, static electricity, interference, seepage, power outages, misoperation, and water shortage. The equipment has overload protection functions; in case of overload or leakage, the equipment will automatically stop. An emergency stop switch is provided; in case of equipment malfunction or other emergencies, the emergency stop switch can be pressed quickly to prevent equipment damage.

- Integrated Modular Assembly

The modular structure allows each module to have 5 or 6 stations. Each independent station operates independently and can be set arbitrarily within the range of 0.2MPa to full load. A failure in one test station will not affect the normal operation of other stations.

Fully Functional: Features rupture detection, real-time monitoring, power-off pressure maintenance, power-off protection, and automatic recovery upon power restoration. It also includes functions for printing and storing test results. The main control interface offers both Chinese and English options, providing multi-language operation.

Includes a pressure measuring device with its reference plane aligned with the constant temperature medium chamber’s horizontal plane.

- Highly User-Friendly Design

Offers an automatic time increment option, as well as manual time increments. This can be used to compensate for invalid intermediate time and to change the test pressure mid-test, meeting the requirements of some special pipe tests.

One main unit can control multiple constant temperature medium chambers. The computer software module automatically collects the temperatures of multiple tanks, can preset the correspondence between the constant temperature medium chambers and pressure stations, and plot temperature control curves.

Features automatic cleaning and automatic pressure relief functions for the solenoid valves.

- Remote Control

Allows for human-machine separation. When the pressure unit is equipped with a network, the test status is uploaded in real time, enabling remote real-time control and viewing of the test status. Currently supports iOS/Android mobile phones/tablets and Windows computers.

The product consists of three parts: Pressure unit, water tanks, and clamps. Each specification and model is selected by the user, and special customization is also available.

Pressure Source Section: High Pressure, Large Flow Rate, Automatic Water Storage, Stable Energy Storage

- The main pressure source uses an imported pump head, forming a self-contained unit; one pressure source can connect to multiple main units;

- Pressure control instruments offer fast response and stable pressure control, employing reliable mechanical gauges;

- High main pressure and large flow rate;

- Wide pressure range, energy storage pressure adjustable from 4-12MPa;

- Low noise, safe and stable;

- The instrument has built-in leakage protection;

- Flexible connection, low noise.

JSW-10M-6 Pressure resistant & burst testing machine for pipes | ||

Max. Pressure | 10MPa | |

Test channel | 6 | |

Control method | Touch screen control | |

Data save | Each channel has power-off data protection; data can be restored upon power-on. | |

specimen size range | φ16~φ710mm | |

Time | Timing | 0~9999h 59min |

Time accuracy | ±0.1% | |

Time resolution | 1s | |

Min. setting unit | min | |

Pressure | Pressure control range | 0.2~10MPa |

Pressure display unit | MPa, bar or PSI | |

Pressure control accuracy | -1%~ +2% | |

Full load range constant pressure control accuracy | Within ±0.3% | |

Pressure display resolution | 0.001MPa、0.01bar or1PSI | |

Measuring range | 4%~100%FS | |

Indicated value tolerance limit | Within 1% | |

■FOB

■CIF

■Package: Wooden case

Working site

Accessory

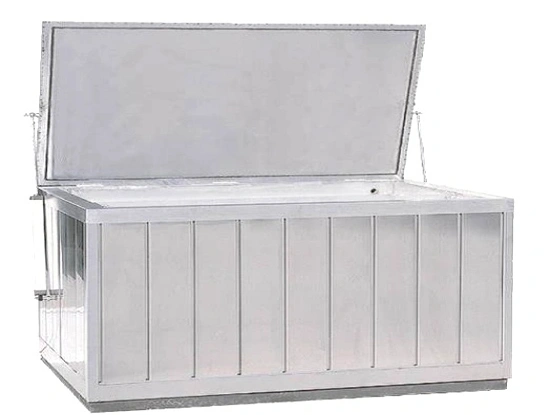

Constant temperature water tank

The hydro-pressure testing machine’s water tank is suitable for long-term hydro-pressure testing of various plastic pipes, instantaneous hydraulic burst testing of pipes, and determination of the time to failure of thermoplastic pipes under long-term constant pressure. It is an essential testing equipment for research institutes, quality inspection departments, and pipe manufacturers

Pipe fixture: GB/T 6111-2018 Type A

This clamp is suitable for pipe hydro-pressure burst testing machines. It is a type A plastic pipe pressure test clamp that can firmly clamp the pipe and is a key auxiliary tool for plastic pipe pressure testing machines. Its specifications are Φ16~Φ1600mm.

- External Structure: Forged from molds, lightweight, and with good load-bearing capacity;

- Sealing Silicone Rings: All O-rings;

- Adapter: PT1/4 internal thread, stainless steel;

- Clamp Interface: M12*1.25 internal thread;

- Clamp Vent: Universal M10 internal thread.

Optional specification: Φ16; Φ20; Φ25; Φ32; Φ40; Φ50; Φ63; Φ75; Φ90; Φ110; Φ125; Φ140; Φ160; Φ180; Φ200; Φ225; Φ250; Φ280; Φ315; Φ355; Φ400; Φ450; Φ500; Φ560; Φ630; Φ710; Φ800; Φ900; Φ1000; Φ1200 (mm) etc.

No. | Specification | Thickness | Max Pipe OD | Max. OD | Length with pipe | O-ring size | Free length | Test pipe length | Total length after clamping | Rated pressure | Weight (set) |

| mm | mm | mm | mm | mm | mm | mm | mm | mm |

|

|

1 | 10 | 71 | 10.8 | 48 | 60 | 10×3.55 | 250 | 330 | 412 | 16Mpa | 0.55kg |

2 | 16 | 71 | 16.8 | 54 | 60 | 16×3.55 | 250 | 330 | 412 | 16Mpa | 0.75kg |

3 | 18 | 71 | 18.8 | 54 | 60 | 18×3.55 | 250 | 330 | 412 | 16Mpa | 0.75kg |

4 | 20 | 71 | 20.8 | 50 | 60 | 20×3.55 | 250 | 330 | 412 | 16Mpa | 1.0kg |

5 | 25 | 71 | 26 | 63 | 60 | 25×3.55 | 250 | 330 | 412 | 16Mpa | 1.1kg |

6 | 32 | 71 | 32.8 | 61 | 60 | 32×3.55 | 250 | 330 | 412 | 16Mpa | 1.5kg |

7 | 40 | 71 | 40.8 | 69 | 60 | 40×3.55 | 250 | 330 | 412 | 16Mpa | 1.6kg |

8 | 50 | 71 | 51 | 80 | 60 | 50×3.55 | 250 | 330 | 412 | 10Mpa | 1.8kg |

9 | 63 | 74 | 64 | 103 | 60 | 63×3.55 | 250 | 330 | 418 | 10Mpa | 2.5kg |

10 | 75 | 80 | 76.5 | 122 | 66 | 73×6 | 250 | 336 | 430 | 10Mpa | 3.4kg |

11 | 90 | 80 | 91.5 | 137 | 66 | 88×6 | 270 | 356 | 450 | 10Mpa | 4.0kg |

12 | 110 | 114 | 112.6 | 170 | 80 | 110×5.7 | 330 | 430 | 578 | 10Mpa | 8.0kg |

13 | 125 | 123 | 127 | 185 | 80 | 120×5.7 | 375 | 475 | 641 | 10Mpa | 9.2kg |

14 | 140 | 123 | 142 | 205 | 80 | 135×5.7 | 420 | 520 | 686 | 10Mpa | 12.3kg |

15 | 160 | 158 | 162 | 232 | 100 | 155×7.0 | 480 | 600 | 816 | 10Mpa | 18kg |

16 | 180 | 167 | 182.5 | 255 | 109 | 175×7.0 | 540 | 669 | 894 | 10Mpa | 23kg |

17 | 200 | 177 | 202.5 | 277 | 109 | 195×7.0 | 600 | 729 | 974 | 10Mpa | 27kg |

18 | 225 | 186 | 227.5 | 302 | 109 | 220×7.0 | 675 | 804 | 1067 | 10Mpa | 28kg |

19 | 250 | 214 | 253 | 335 | 129 | 245×8.6 | 750 | 899 | 1198 | 10Mpa | 44kg |

20 | 280 | 220 | 283 | 382 | 140 | 275×12 | 840 | 1000 | 1300 | 6Mpa | 56kg |

21 | 315 | 283 | 320 | 425 | 180 | 310×12 | 945 | 1145 | 1531 | 6Mpa | 66kg |

22 | 355 | 287 | 360 | 465 | 172 | 350×12 | 710 | 902 | 1304 | 6Mpa | 100kg |

23 | 400 | 317 | 405 | 516 | 190 | 390×16 | 800 | 1010 | 1454 | 6Mpa | 122kg |

24 | 450 | 317 | 455 | 566 | 190 | 440×16 | 900 | 1110 | 1554 | 6Mpa | 140kg |

25 | 500 | 362 | 505 | 642 | 258 | 490×16 | 1000 | 1278 | 1744 | 6Mpa | 220kg |

26 | 560 | 392 | 567 | 702 | 264 | 550×18 | 1120 | 1404 | 1924 | 6MPa | 250kg |

27 | 630 | 447 | 637 | 772 | 274 | 620×18 | 1260 | 1554 | 2174 | 6MPa | 282kg |

28 | 710 | 433 | 717 | 857 | 292 | 705×18 | 1420 | 1732 | 2306 | 3MPa | 374kg |

29 | 800 | 484 | 809 | 948 | 353 | 795×18 | 1600 | 1973 | 2588 | 3MPa | 512kg |

30 | 900 | 569 | 909 | 1078 | 415 | 890×30 | 1800 | 2235 | 2958 | 3MPa | 661kg |

31 | 1000 | 667 | 1009 | 1178 | 423 | 995×30 | 2000 | 2443 | 3354 | 2.5Mpa | 806kg |

32 | 1200 | 697 | 1210 | 1378 | 433 | 1190×32 | 2400 | 2853 | 3814 | 2.5Mpa | 1026kg |

33 | 1600 | 737 | 1615 | 1678 | 470 |

| 3200 | 3690 | 4694 | 1.5Mpa |