Element Analyzer

Element Analyzer

Atomic Absorption Spectrophotometer | Mercury Analyzer |

Automatic Graphite Digestion Robot

Home>>Element Analyzer>>Direct mercury analyzer

Direct mercury analyzer

HGA series direct mercury analyzer is a special mercury measuring equipment in line with the internationally accepted mercury detection method (EPA-7473) and the development requirements of domestic environmental protection detection methods. The instrument can accurately and quickly detect the content of toxic heavy metal element mercury in samples without chemical digestion pretreatment.

Application:

It is applicable to the determination of mercury in samples in the fields of environmental protection, food safety, disease control, medicine and medical treatment, agriculture, geology and mining, metallurgy, coal, petrochemical, cosmetics, soil, urban water supply and drainage, teaching and research.

Standard:

EPA-7473

AVAILABLE MODELS

HGA-100 Direct mercury analyzer

HGA-200 Direct mercury analyzer

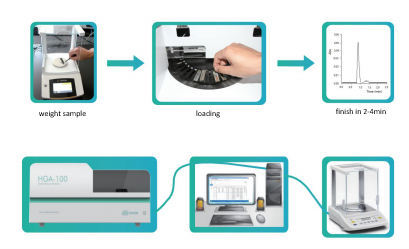

HGA-100 working flow

Sampling (solid weighing, liquid suction, gas collection) – Automatic loading detection – Obtain detection data within 5 minutes

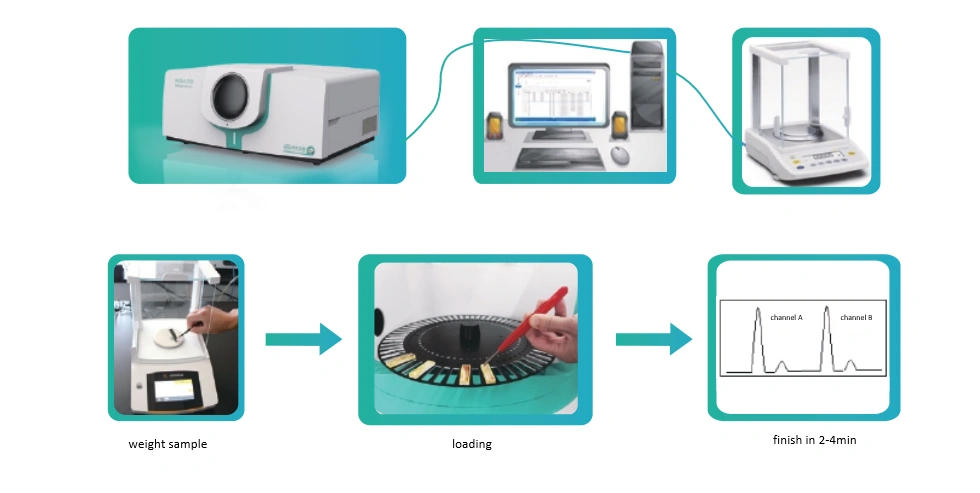

HGA-200 working flow

Sampling – automatic loading – about 5 minutes to obtain two detection data – sample detection efficiency of 2.5 min/pcs

Application

Detailed Technical Specification

Application fields:

It is applicable to the determination of mercury in samples in the fields of environmental protection, food safety, disease control, medicine and medical treatment, agriculture, geology and mining, metallurgy, coal, petrochemical, cosmetics, soil, urban water supply and drainage, teaching and research.

Product features:

- Wide applicability: applicable to solid, liquid and gas samples.

- Easy operation: without chemical digestion pretreatment, the experimenter only needs to weigh the sample and directly inject the sample with one key for measurement.

- Low detection cost: no chemical reagent is consumed during the operation of the instrument to reduce the operation cost of the laboratory.

- High analysis efficiency: the analysis time is less than 5 minutes/time, and 40 sample plates are equipped to improve the detection efficiency.

- No mercury loss and memory effect: direct injection has no mercury loss, and the whole process temperature control design reduces the mercury memory effect.

- Good repeatability and high accuracy; integrated flow path, high-efficiency composite catalytic agent, nano coated-gold amalgam material and other purification processes to ensure stable and accurate test results.

- Environmental protection: green design concept; no harmful chemicals are used in the whole analysis process, and the exhaust gas is highly absorbed by the purification device.

- High catalytic efficiency: high efficiency catalyst and other patented technologies remove matrix interference, improve measurement repeatability and stability, and improve the sensitivity of the instrument test.

- Double beam correction to reduce error: the non-reflective double beam design can correct the drift and fluctuation of the light source in real time. There is no mirror or proportional reflection mirror to avoid the correction error caused by mirror contamination.

- Automatic input of balance weighing: the weighing data can be imported into the software system in real time through the data interface of the electronic balance to avoid operation error.

- Automatic sample injection system: equipped with 40 positions automatic sample injection tray to realize unattended and automatic measurement.

- Convenient software operating system: multithreading, embedded software design and real-time monitoring of dynamic interface to realize personalized and convenient operation.

- Photodetector: mercury spectral lines(253.7nm) were measured with a highly selective imported UV photodetector.

- High efficiency exhaust gas purification device: a high-efficiency adsorption activated carbon purification system is equipped to prevent the secondary pollution of mercury waste gas to the environment.

- Rapid handling of emergencies: direct measurement without digestion provides technical data for the formulation of emergency response measures in face of sudden mercury pollution incidents.

Operation process:

sampling (solid weighing; liquid suction; gas collection)—-automatic sample injection and detection—-get the test data within 5 minutes

weigh the sample—-put sample into the sample boat—-complete the test within 2-4 minutes

Application fields:

It is applicable to the determination of mercury in samples in the fields of environmental protection, food safety, disease control, medicine and medical treatment, agriculture, geology and mining, metallurgy, coal, petrochemical, cosmetics, soil, urban water supply and drainage, teaching and research.

Product features:

- Wide applicability: applicable to solid, liquid and gas samples.

- Multi-channel detection: based on the dual channel design, two samples can be tested simultaneously within 5min, and the analysis efficiency is improved by 100%.

- Easy operation: without chemical digestion pretreatment, the experimenter only needs to weigh the sample and directly inject the sample with one key for measurement.

- Low detection cost: no chemical reagent is consumed during the operation of the instrument to reduce the operation cost of the laboratory.

- High analysis efficiency: the analysis time is less than 5 minutes/time, and 60 sample plates are equipped to improve the detection efficiency.

- No mercury loss and memory effect: direct injection has no mercury loss, and the whole process temperature control design reduces the mercury memory effect.

- Good repeatability and high accuracy; integrated flow path, high-efficiency composite catalytic agent, nano coated-gold amalgam material and other purification processes to ensure stable and accurate test results.

- Environmental protection: green design concept; no harmful chemicals are used in the whole analysis process, and the exhaust gas is highly absorbed by the purification device.

- High catalytic efficiency: high efficiency catalyst and other patented technologies remove matrix interference, improve measurement repeatability and stability, and improve the sensitivity of the instrument test.

- Double beam correction to reduce error: the non-reflective double beam design can correct the drift and fluctuation of the light source in real time. There is no mirror or proportional reflection mirror to avoid the correction error caused by mirror contamination.

- Automatic input of balance weighing: the weighing data can be imported into the software system in real time through the data interface of the electronic balance to avoid operation error.

- Automatic sample injection system: equipped with 60 positions automatic sample injection tray to realize unattended and automatic measurement.

- Convenient software operating system: multithreading, embedded software design and real-time monitoring of dynamic interface to realize personalized and convenient operation.

- Photodetector: mercury spectral lines(253.7nm) were measured with a highly selective imported UV photodetector.

- High efficiency exhaust gas purification device: a high-efficiency adsorption activated carbon purification system is equipped to prevent the secondary pollution of mercury waste gas to the environment.

- Rapid handling of emergencies: direct measurement without digestion provides technical data for the formulation of emergency response measures in face of sudden mercury pollution incidents.

Operation process:

sampling—-automatic sample injection —-get the test data within 5 minutes—- sample detection efficiency: 2.5min/piece

weigh the sample—-put sample into the sample boat—-complete the test within 2-4 minutes

▪CIF

▪Package: Wooden case