Building Envelope & Fenestration Testing Systems

Building Envelope & Fenestration Testing Systems

Our Building Envelope & Fenestration Testing Systems represent a comprehensive, laboratory-grade and field-deployable solution portfolio designed to evaluate the performance, safety, durability, and energy efficiency of the entire building enclosure. This integrated suite covers materials, components, and complete systems—from foundational glass and sealants to complex curtain walls, windows, doors, and opaque wall assemblies. Engineered for precision and reliability, our systems enable manufacturers, testing laboratories, research institutions, and quality control agencies to validate product compliance, drive innovation, and ensure long-term building integrity under simulated and real-world environmental stresses.

Application Industries

Door, Window & Curtain Wall Manufacturers: For pre-delivery quality checks and new product development testing.

Glass Processors: Testing glass for thermal insulation, soundproofing, safety, and optical properties.

Testing & Certification Centers: Providing authoritative third-party test reports.

Construction & Supervision Companies: For material acceptance checks and on-site installation quality inspections.

Research Institutes & Universities: For building material performance research and education.

Real Estate Developers: Controlling the quality and performance of purchased products.

Key Test Items

Our equipment primarily tests the following six categories of performance:

Strength & Durability: Wind load resistance, impact resistance, repeated opening/closing life, hardware durability.

Sealing & Waterproofing: Air leakage, water leakage, sealant aging resistance.

Thermal & Energy Performance: Insulation value (U-value) of windows/walls, solar heat gain, condensation risk.

Acoustic & Optical Performance: Sound insulation capability, glass light transmittance.

Glass-Specific Tests: Dew point in insulated glass (fogging), various optical properties, impact and thermal shock resistance of safety glass.

On-site & Whole-Building Tests: Performance of installed units, overall building air tightness.

Applicable Standards

Chinese National Standards (GB): e.g., for door/window performance (GB/T 7106), curtain wall performance (GB/T 15227), glass safety (GB 15763), energy efficiency (GB/T 8484).

International Standards: e.g., American ASTM, AAMA standards; European EN standards.

Industry Codes: Relevant industry standards such as Chinese building industry (JG) and construction engineering (JGJ) codes.

AVAILABLE MODELS

Building Doors, Windows & Curtain Walls Testing Equipment

This equipment series is the core solution for testing the complete performance of building openings and façades. It simulates real-world environmental stresses to rigorously evaluate the airtightness, watertightness, wind resistance, thermal insulation, soundproofing, and operational durability of doors, windows, curtain walls, and related hardware. From laboratory-grade large chambers for full-scale mock-ups to portable devices for on-site quality checks, it provides authoritative data for product R&D, quality control, and certification.

Building Wall Envelope Systems

This category focuses on testing the performance of opaque building wall systems. Key equipment includes Hot Box testers for accurately measuring the thermal insulation value (U-value/k-value) of wall assemblies and composite panels. It also covers systems for evaluating weathering resistance, wind load resistance, and in-situ thermal performance of external wall insulation and cladding systems. These solutions are essential for validating building energy efficiency, material durability, and compliance with green building standards.

Glass Testing Equipment

This suite provides specialized instruments for comprehensive testing of architectural glass and insulating glass units (IGUs). It covers critical properties such as optical performance (light/solar transmittance), thermal properties (U-value, emissivity), mechanical safety (impact resistance, fragmentation), and durability (dew point, UV resistance, thermal shock). These precise tools enable glass manufacturers and processors to ensure product quality, performance, and compliance with stringent safety and energy codes

Axle, Shaft testing rig

This series of machines can perform torsional fatigue tests on various shaft and rod components, such as torsional stiffness and strength tests, suitable for automotive transmission shafts, constant velocity universal joints, ball cages, half shafts, drive axle shells, etc.

Standard:

QC/T649 Automotive Steering Transmission Shaft Assembly Performance Requirements and Test Methods

QC/T29082 Technical Conditions and Bench Test Methods for Automobile Transmission Shaft Assembly

Torque range: 500~40000 N·m

Force measurement accuracy: Class 0.5~1

Load waveform: sine wave, square wave, etc.

The automobile stabilizer fatigue testing bench is used to test the fatigue life of the automobile stabilizer. It applies electro-hydraulic servo technology, uses a hydraulic system for loading, and has a dedicated servo controller to output instructions to the linear servo actuator to test the loading of the stabilizer.

This test rig can perform fatigue, stiffness, and strength tests on the stabilizer bar. When equipped with an environmental chamber, tests can be conducted in high and low temperature environments, as well as muddy water environments. The control system can also perform spectrum iteration for comprehensive performance testing

Standard:

JASO C617 Automotive Parts Stabilizer Bar

Single actuator test force: 25kN~100kN

Force measurement accuracy: Class 0.5~1

Load waveform: sine wave, square wave, path spectrum, etc

The Thrust rod fatigue loading test rig applies electro-hydraulic servo technology and uses a hydraulic system for loading. A dedicated servo controller can output commands to test the linear servo actuator. It is also possible to test the straight push rod, diagonal push rod, and Vshaped push rod by equipping them with different fixtures. Axial, radial, torsional, yaw, and coupled fatigue tests can also be conducted on the V-shaped push rod according to requirements.

The Rear axle torsion beam test rig is used to test the rear axle torsion beam, shock absorber, and suspension spring assembly. Applying electro-hydraulic servo technology, hydraulic system loading is adopted, and a dedicated servo controller is used to output instructions to the linear servo actuator for experimentation.

This bench can be used for: parallel wheel jump force endurance test, lateral fatigue endurance test, 180 ° reverse displacement torsional fatigue test of left and right wheel cores, forward and backward braking fatigue endurance test, single side longitudinal force loading endurance test of wheel cores, single side vertical force fatigue test, static strength test, torsional stiffness test, etc.

Testing force: 25kN;

Force measurement accuracy: Class 0.5~1

Loading waveform: Sine wave, square wave, road spectrum, etc

The Axle test rig can be equipped with 2 to 6 actuators to simulate the vertical, lateral, and longitudinal loads of the axle. The main components include: actuators, loading frames, work platforms, hydraulic systems, control systems, etc. The test rig is hydraulic loaded and suitable for fatigue performance testing of vehicle axles.

Standard: QC/T533 Commercial Vehicle Drive Axle Assembly

Test force: 200kN~1000kN;

Force testing accuracy: Class 0.5~1

Load waveform: sine wave, square wave, path spectrum, etc.

The Front subframe and loading arm test rig applies electro-hydraulic servo technology, uses a hydraulic system for loading, and conducts experiments by outputting instructions to the linear servo actuator through a dedicated servo controller.

This test rig can perform durability tests on the subframe and loading arm, driving impact tests, fatigue tests with lateral force in the same direction, static strength tests at the installation point, stiffness tests, X/Y impact tests on the swing arm, and static strength tests on the loading arm.

Testing force: 25kN~500kN

Force measurement accuracy: Class 0.5~1

Loading waveform: sine wave, square wave, path spetrum, etc.

The suspension spring fatigue test rig uses a hydraulic system to load and conducts experiments on the output commands of linear servo actuators through a dedicated servo controller. It can be used to test the fatigue life and stiffness of suspension springs. When equipped with an environmental chamber, experiments can be conducted in high and low temperature environments.

Air suspension axle joint test: Adopting a multi-channel configuration to achieve maximum restoration of installation conditions, multiple loading channels can be configured, and multiple testing methods are applicable. Strong load-bearing capacity, high accuracy, with functions such as phase coordination and amplitude coordination.

For example, it can be equipped with four channels (2 vertical, 1 horizontal, and 1 longitudinal). The vertical channel is used to simulate the wheel load state, and the lateral and longitudinal channels are used to simulate the vehicle’s bearing of lateral and longitudinal loads.

Test force: 10kN~100kN;

Force measurement accuracy: Class 0.5~1

Load waveform: sine wave, square wave, path spectrum, etc.

Detailed Information

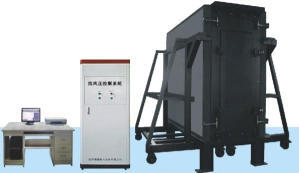

Purpose: Tests the three primary physical properties of building doors and windows: Air Permeability, Water Tightness, and Wind Load Resistance.

Applicable Standards: GB/T 7106

Model | MWS-2121A | MWS-2424A | MWS-3030A |

Wind Pressure Measurement Range | -200 Pa ~ +200 Pa | ||

Displacement Measurement Range | 0 ~ 60 mm | 0 ~ 80 mm | |

Pressure Transmitter Accuracy | Class 0.5 | ||

Displacement Gauge Accuracy | Class 0.2 | ||

Air Flow Measurement Range | 0.1 – 590 m³/h | ||

Water Flow Range | 0.35 – 45 L/min | ||

Specimen Size (mm) | 600×600 ~ 2100×2100 | 600×600 ~ 2400×2400 | 600×600 ~ 3000×3000 |

Control Cabinet Dimensions (mm) | 730 × 600 × 1760 (L×W×H) | ||

Equipment Footprint (mm) | 2960 × 5000 × 2900 (L×W×H) | 3260 × 5000 × 3350 (L×W×H) | 3860 × 5000 × 3950 (L×W×H) |

Power Supply | AC 380V, 14 kW | AC 380V, 21 kW | |

Purpose: Determines the Thermal Transmittance (U-value) and Condensation Resistance Factor of external doors and windows.

Applicable Standards: GB/T 8484

Key Specifications:

Model | MC-BW1821 | MC-BW1824 | MC-BW2121 | MC-BW2424 |

Maximum Specimen Size (mm) | 1800 × 2100 | 1800 × 2400 | 2100 × 2100 | 2400 × 2400 |

Chamber Dimensions (mm) | 3920 × 3610 × 4200 | 3920 × 3610 × 4500 | 3920 × 4000 × 4200 | 3920 × 4210 × 4500 |

Environmental Space Dimensions (mm) | 4600 × 4400 × 4300 | 4600 × 4400 × 4600 | 4600 × 4700 × 4300 | 4600 × 5000 × 4600 |

Temperature Measurement Accuracy | 0.2°C | |||

Temperature Control Accuracy | 0.1°C | |||

Heating Power Accuracy | Class 0.2 | |||

Heating Power Range | 10 ~ 900 W | |||

Test Method | Fully Automatic Microcomputer Control | |||

Power Supply | 380V, 8 kW | |||

Weight | 1450 kg | 1500 kg | 1600 kg | |

Purpose: Performs static and dynamic wind uplift resistance tests for metal roofing systems and evaluates their physical performance.

Applicable Standards: GB/T 31543, JGJ 255, FM 4471, ANSI FM 4474, ETAG 006, etc.

Key Specifications:

Pressure Control: Range: -10,000 Pa to +10,000 Pa; Accuracy: ±0.5%.

Flow Measurement:

Air Flow: 0 – 360 m³/h (±2.5%).

Water Flow: 0 – 6500 L/h (±2.5%).

Displacement Measurement: Range: 0 – 80 mm; Accuracy: Class 0.1.

Cyclic Testing: Programmable number of cycles with 100% control accuracy.

Max. Specimen Size: 7300 mm × 3700 mm.

Power Requirements: AC 380V, 65 kW.

Purpose: Field testing of air permeability for installed building doors and windows.

Applicable Standards: JG/T 211, JGJ 132

Key Specifications:

Pressure Range: -200 Pa to +200 Pa (±0.5%).

Air Flow Range: 0.2 – 326 m³/h (±1.5%).

Test Range (Specimen): Height & Width ≤ 1800 mm.

Power Supply: AC 220V, 500W.

Purpose: Measures the overall air tightness of buildings (envelopes) and local air leakage using the fan pressurization method.

Applicable Standards: GB/T 34010

Key Specifications:

Indoor-Outdoor Pressure Differential: ±50 Pa.

Max. Air Flow Rate: 7500 m³/h (±5%).

Adjustable Frame: Width: 610 – 1010 mm; Height: 1325 – 2450 mm.

Power Supply: AC 220V, 50Hz, 750W.

Purpose: Automated life-cycle testing for various door/window hardware. Can be extended to test doors for security, vehicles (high-speed rail, cars), etc.

Key Specifications:

Configuration: Floor-mounted industrial robot.

Payload Capacity: 20 kg.

Repeatability: ±0.06 mm.

Grippers: Features wear-resistant, four-wheel flexible grippers for different opening types (side-hung, sliding). Optional force sensors and specialized fixtures available.

Purpose: Comprehensive performance testing for curtain walls, including air tightness, water tightness, wind load resistance, and inter-story deformation performance.

Applicable Standards: GB/T 15227, GB/T 21086, GB/T 18250, JGJ 102, 133, ASTM E283/E330/E331, AAMA 501.1/501.4, etc.

Key Specifications (Models: JSW-K40-60, JSW-K60-90, JSW-K100-160):

Model | JSW-K40-60 | JSW-K60-90 | JSW-K100-160 |

Wind Pressure Test Range | -8000 Pa ~ +8000 Pa | -10000 Pa ~ +10000 Pa | -10000 Pa ~ +10000 Pa |

Air Flow Test Range | 0 – 360 m³/h | 0 – 1500 m³/h | 0 – 3600 m³/h |

Water Flow Test Range | 4 L/(min·m) |

|

|

Displacement Test Range | 0 ~ 50 mm / 0 ~ 100 mm | 0 ~ 50 mm / 0 ~ 160 mm | 0 ~ 50 mm / 0 ~ 160 mm |

Equipment Power | 50 kW | 70 kW | 120 kW |

Plenum Chamber Dimensions | (Max. Specimen Width + 2200 mm) × 4500 mm × (Max. Specimen Height + 2500 mm) | Customizable based on order specifications |

|

Power Supply | Three-phase, five-wire system, AC 380V, 50 Hz |

|

|

Weight | 15 tons | 25 tons |

|

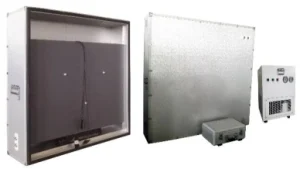

Purpose: Measures the thermal transmittance (U-value/k-value) of building walls and composite panel materials using the Guarded Hot Box method.

Applicable Standards: GB/T 13475

Key Specifications (Models: CD-WTF1515, 1212, 1010):

Model | CD-WTF1515 | CD-WTF1212 | CD-WTF1010 |

Metering Box Temperature Control Range | 10~50°C | ||

Cold Box Temperature Control Range | -10~-21°C | ||

Guard Box Temperature Control Range | 10~50°C | ||

Metering Box Power Measurement & Control Range | 10~400W | ||

Specimen External Dimensions (mm) | 1750 × (≤500) × 1750 | 1450 × (≤400) × 1450 | 1270 × (≤330) × 1270 |

Equipment External Dimensions (mm) | 2965 × 2385 × 2428 | 2965 × 2080 × 2128 | 2270 × 1570 × 1802 |

Metering Unit Dimensions (mm) | 1500 × 1500 | 1200 × 1200 | 1000 × 1000 |

Maximum Specimen Thickness (mm) | ≤500 | ≤400 | ≤330 |

Power Supply | AC 380V, Power: 7 kW | AC 380V, Power: 6 kW | AC 380V, Power: 6 kW |

Required Floor Area (mm) | 3960 × 6000 × 2628 | 3960 × 5400 × 2428 | 3270 × 4350 × 2280 |

Weight | 560 kg | 480 kg | 320 kg |

Purpose: In-situ or laboratory measurement of heat transfer coefficient (U-value), temperature, and heat flux for building envelopes.

Applicable Standards: JGJ/T 132, JGJ/T 357, GB/T 23483

Key Specifications

Model | CD-JZXC-WR | CD-JZXC-WL | CD-JZXC-WR-2 | CD-JZXC-WL-2 |

In-Box Temperature Control Range | Ambient ~ 40°C | 5 ~ 40°C | Ambient ~ 40°C | 5 ~ 40°C |

Model Description | Single Hot Box (1-to-1) | Single Cold Box (1-to-1) | Dual Hot Boxes (1-to-2) | Dual Cold Boxes (1-to-2) |

Measurement Accuracy | 0.25°C | |||

Temperature Control Fluctuation | ±0.2°C | |||

Heat Flux Meter Range | 0 — ±20 mV | |||

Power Supply | AC 220V, Power ≥ 600W, requires proper grounding | |||

Equipment Dimensions | 1290 × 1290 × 270 mm | Multiple Refrigerant Source Box | Dual Boxes | Dual Boxes + Dual Refrigerant Source Boxes |

Weight | 45 kg | 90 kg | 90 kg | 180 kg |

Model Selection | Models can be selected and configured by the user according to their needs | |||

Purpose: Accelerated weathering resistance testing for External Thermal Insulation Composite Systems (ETICS).

Applicable Standards: JG 429, JGJ 144, JG 149, JG 158, JGJ 253

Key Specifications:

Air Temperature: Range: -25°C to +75°C; Control Precision: < ±0.3°C of target.

Water Temperature: 15 ± 2°C.

Relative Humidity: Range: 20% – 100% RH (±3%).

Water Spray Flow: 0 – 2000 L/h.

Power Supply: AC 380V, 28 kW.

Purpose: Determines the wind load resistance (negative pressure) of external wall insulation systems.

Applicable Standards: JGJ 144

Key Specifications:

Wind Pressure Control: Range: 0 to -7000 Pa; Accuracy: ≤ ±5% of target pressure.

Cyclic Testing: Programmable number of cycles. Pulse timing control for pressurization, hold, and depressurization phases.

Power Supply: AC 380V, 21 kW. Requires an air compressor (0.4-0.8 MPa).

Purpose: Measures the dew point temperature and evaluates the seal integrity of insulated glass units (IGUs).

Standards: GB/T 11944, GB 50411

Key Specifications:

Model | JSW-LD-B | JSW-LD-Y | JSW-LD-F |

Readout/Display Type | Analog Meter | Analog Meter | Touchscreen |

Cooling Method | Dry Ice | Cascade Compressor | Cascade Compressor |

Minimum Temperature | -80°C | -65°C | -65°C |

Power Supply | Battery | AC 220V, 1.5 kW | AC 220V, 1.5 kW |

Purpose: Comprehensive optical and solar property testing for architectural glass. Optionally compatible with reflective thermal insulation coatings.

Test Items: Visible light transmittance/reflectance; Solar direct transmittance/ reflectance/ absorptance, total solar transmittance; SHGC; UV transmittance/reflectance. Optional: Solar/NIR reflectance of coatings, and changes after soiling or aging.

Standards: GB/T 2680, ISO 9050, JGJ/T 151, JG/T 235 (optional).

Key Specifications:

Measurement Range: 0% – 100%.

Wavelength Range: 250 – 2800 nm (usable: 300-2500 nm).

Accuracy: Wavelength ±0.5nm (UV/VIS) / ±4nm (NIR).

Integrating Sphere: Φ60 mm, high diffuse reflectance.

Geometry: 5° (reflection), 0° (transmission).

Power: 220V AC, 500W.

Dimensions: ~800 × 600 × 280 mm.

Purpose: Determines the U-value (thermal transmittance) of insulated glass using the Guarded Hot Plate method.

Standards: GB/T 22476.

Key Specifications:

Model | JSW-CR-A | JSW-CR-B |

Test Configuration | Dual Specimens 800×800 (mm) | Single Specimen 800×800 (mm) |

Specimen Thickness | Up to ~100 mm | |

Hot Plate Temperature | 17.5°C | |

Cold Plate Temperature | 2.5°C | |

Measurement Accuracy | ±2% | |

Power Supply | AC 220V, 5 kW | AC 220V, 8.5 kW |

Dimensions (L × W × H) | 1720 × 1280 × 2090 (mm) | 1460 × 1250 × 2015 (mm) |

Weight | 620 kg | 620 kg |

Purpose: Performs ball-drop impact and headform impact tests.

Standards: GB 15763.2.

Key Specifications:

Drop Height: 1000 – 6000 mm (adjustable).

Control: Touchscreen.

Impactors: Steel balls (227g, 1040g) and 10 kg headform.

Frame Size: ~6.9 × 2.8 × 1.5 m.

Power: 220V / 380V, 1.5 kW.

Building Doors, Windows & Curtain Walls Testing Equipment can simulate real-world environmental conditions to measure performance.

Airtightness/ Watertightness/ Wind Resistance: A sealed chamber applies controlled air pressure and water spray to the test specimen while measuring air leakage, water penetration, and deformation.

Thermal Insulation: The “hot box-cold box” method places the sample between two temperature-controlled spaces. The heat required to maintain a temperature difference is used to calculate the U-value.

Sound Insulation: Sound is generated in a source room, and the reduction in sound pressure level passing through the specimen is measured in a receiving room.

Mechanical Durability: Robotic arms or actuators automatically open, close, and lock doors/windows repeatedly to test hardware lifespan.

Building Wall Envelope Systems can evaluate wall system performance through steady-state heat transfer and environmental simulation.

Thermal Transmittance (U-value): The guarded hot box method places the wall between hot and cold chambers. The heating power required to maintain a stable temperature difference is measured to calculate thermal resistance.

Weathering & Wind Load Resistance: Specimens undergo accelerated aging cycles (temperature, humidity, UV, water spray). Wind resistance is tested by applying controlled negative pressure to check deformation and failure limits.

Glass Testing Equipment can analyze glass performance using optical spectroscopy, steady-state heat flow, and mechanical impact principles.

Optical & Solar Properties: A spectrophotometer measures transmission, reflection, and absorption across light wavelengths to calculate visible light transmittance and solar heat gain coefficient (SHGC).

Thermal Transmittance (U-value): The guarded hot plate method sandwiches glass between temperature-controlled plates. The heating power required to maintain a temperature gradient determines the U-value.

Dew Point: A cold probe cools the glass surface locally; optical sensors detect condensation to assess seal integrity.

Impact Resistance: A standardized impactor (steel ball or shot bag) is dropped from a specified height to test breakage behavior and safety performance.

Development History of Building Envelope & Fenestration Testing Systems

Foundation & Basic Performance (1950s-1980s)

Early Simple Testing

The start of building envelope testing came from new needs for energy saving and comfort in buildings. After World War II, with many buildings being constructed, simple testing methods began to form.

Doors/Windows Testing: Early tests focused on basic weather protection – simple air and water leakage tests using basic fans and water spray systems, mainly for home windows.

Wall Systems Testing: The 1970s energy crisis pushed the need for heat performance testing. Simple “hot box” devices were made to measure how well walls kept heat in, though methods were not yet standard.

Glass Testing: First equipment could only test basic light passing through glass and simple heat shock tests for early double-pane windows.

This time period saw the creation of first testing standards for air leakage and window performance in America and Europe.

System Development & Standard Setting (1980s-2000s)

Computer Use and Better Testing

The 1980s-1990s brought big changes as computers allowed automatic control and data collection:

Complete Performance Testing: Multi-function testing rooms appeared that could do air, water, and strength tests one after another. The standard “pressure box” became common for window testing worldwide. Testing rules became more similar across countries.

Better Heat Testing: Hot box systems improved with computer-controlled temperature settings, allowing exact measurement of heat transfer for complex walls and curtain walls.

Special Glass Testing: Equipment improved to measure not just light passing through but also solar heat gain and thermal performance as energy rules became stricter.

Important changes included automatic repeat testing for long-term use, early earthquake testing for curtain walls, and connecting these three testing areas into one complete building envelope evaluation.

Green Building & Smart Technology (2000s-Present)

High Performance and Digital Testing

The 21st century’s focus on green building and digital technology changed testing:

Whole Building Science: Equipment now copies extreme weather – hurricane winds, heavy rain, and temperature changes – testing complete wall and window systems together. Testing of full building corners became possible in large testing rooms.

Energy & Environment Testing: Testing expanded to important green building measures:

Better light measurement tools for exact solar heat gain

Full-size daylight and solar heat gain testing rooms

Very accurate heat transfer measurement meeting strict green building standards

Whole building air tightness testing became standard

Digital & Robot Advances: Computer models now guide physical testing. Robot systems do complex long-term use testing (thousands of open/close cycles). Internet-connected sensors provide live data, and results connect directly with building digital models.

Current Integration: Today’s best testing places combine all three areas – testing complete building outer wall systems that include glass, frames, walls, and connections together. This complete approach solves important problems like heat loss at connections, water formation risk, and long-term performance that separate testing could not predict.

Future Direction (Now-2030)

The industry is moving toward:

Live performance watching with built-in sensors

Climate-specific testing for changing weather conditions

Material reuse testing for circular building systems

Smart computer testing that predicts 50-year performance from short-term tests

From separate testing of parts to complete evaluation of building outer walls, testing development has followed – and made possible – building progress toward better performance, stronger buildings, and greener construction.