Balancing Machine

Home>>Straightening machine & Balancing machine>>Balancing Machine

Balancing machine

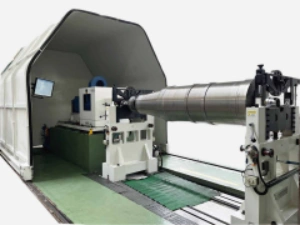

For locomotive balancing

▶Large crank shaft

▶Large propeller shaft

▶Specialized balancing machine for wheel set

Universal balancing machine for various kinds of hydromechanical rotor

▶Blower

▶Aeroengine

▶Turbine

▶Turbocharger

▶Multiple stage Pump

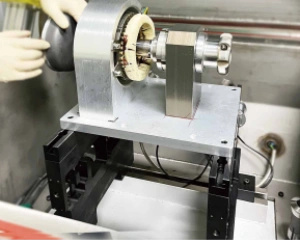

Special balancing machine

▶Balancing machine for antimagnetic application

▶Spot dynamic balancing instrument

▶Micro soft-bearing balancing machine

▶Bearing bush balancing machine for aeroengine

▶Winder balancing machine used in textile machine industry

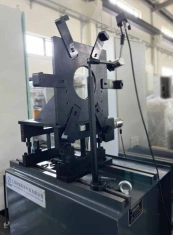

Frame structure balancing machine

▶Frame structure balancing machine for impeller and fan assembly, machine tool driving shaft unit, middle and small motor assembly, etc.

▶Soft-bearing series frame structure balancing machine for high precision of assembled and self-driving rotor

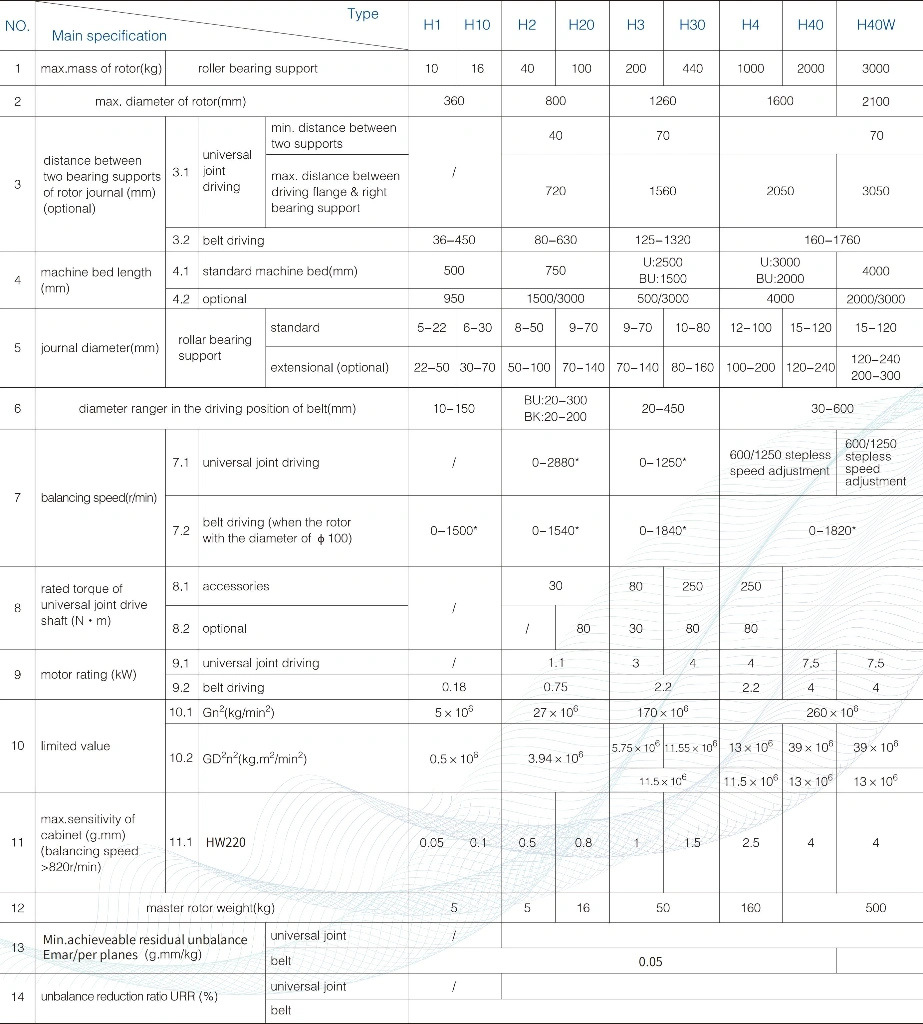

AVAILABLE MODELS

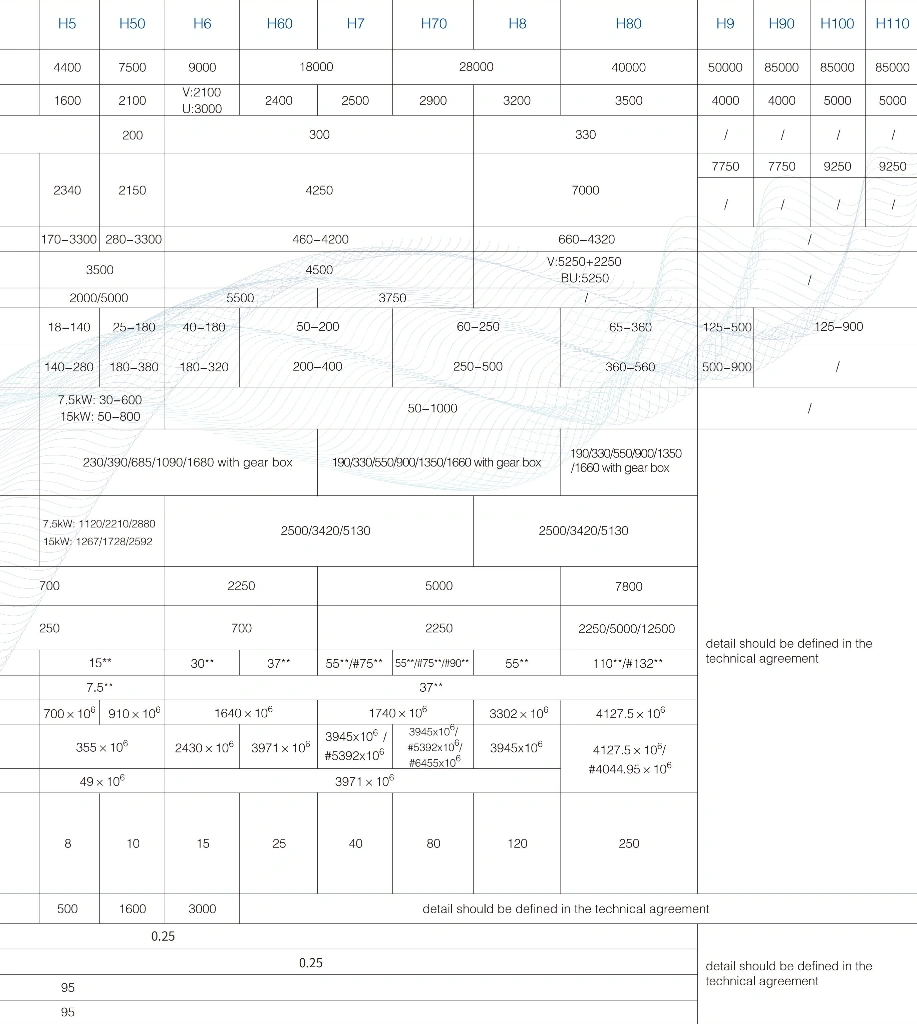

Hard Bearing Balancing Machine

- H1BK: 10kg

- H2BK: 40kg

- H3BU: 200kg

- H4U: 1000kg

- H6U: 9000kg

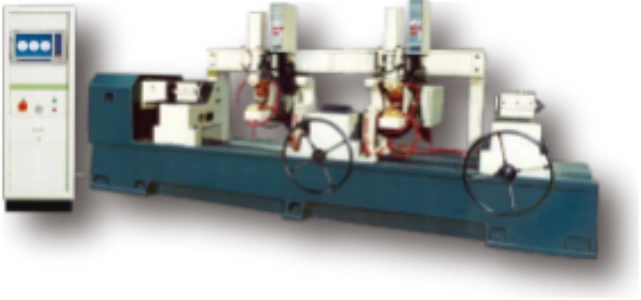

Propeller shaft balancing machine

- MBA-11S: 5-100kg

- MBB-11S: 5-100kg

- MBD-11S: 5-100kg

- MBC-18S: 6-160kg

Single/Dual-plane Vertical Hard-Bearing Balancing Machine

- YDL10: 10kg

- YDL30: 30kg

- YDL100: 100kg

- YLS10: 10kg

- YLS30: 30kg

- YLS100: 100kg

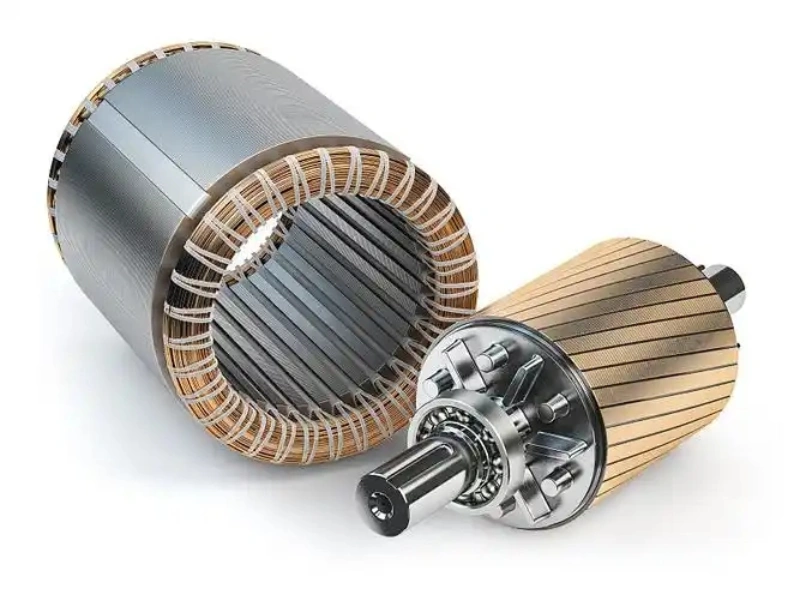

APPLICATION

Other Available Model

Balancing machine for antimagnetic application

- Roller made of copper

- Pedestal and belt driving system made of stainless steel

- Expected precision achieved by avoiding the effect from magnetic rotor such as permanent magnet motor

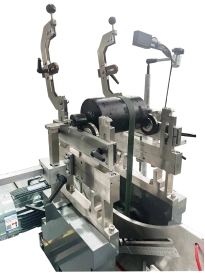

Frame structure balancing machine of self-driving

frame structure balancing machine for impeller and fan assembly , machine tool driving shaft unit , middle and small motor assembly , etc.

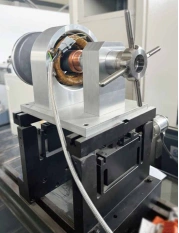

Automatic rotor balancing machine

Automatic rotor balancing machine is mainly used for balancing small motors which needed in auto , such as auto rearview-mirror adjusting motor, seat motor, windshield motor, wiper motor, oil pump motor, starter motor, generator and other DC motors.

Realizes all automation of measurement and weight removal , and also can be equipped with material belt to make work efficiently.

Brake disc two-station automatic balancing machine

Brake disc two-station automatic balancing machine is used for balancing and correction of single-plane disc. The equipment is controlled by PLC, which complete measuring calculation and control. Man-machine conversation. It can modified by drilling/milling, coating and fusion. It has the characteristics of high accuracy and efficiency, suitable for brake disc.

Self-driving balancing machine for small fan

The device is a self-driving balancing machine,which is used for overall balance of small fan, such as a heating fan. This equipment has wide measuring range and application. Considering the whole components balancing, eliminating the unbalance caused by the parts and assembly errors, improving the product quality.

Automatic hard/soft bearing vertical balancing machine for disc type motor

In order to meet the market demand, manual, automatic hard/soft bearing vertical balancing machine capable for disc type rotors of auto industry, unbalance corrected by drilling or milling manually or automatically. We also have vertical balancing machine for large vertical serving rotors and type for large scale and high speed balance of centrifuge drum.

Detailed Technical Specification

This machine is especially suitable for balancing the micro and small motor rotors, turbo charger and rotors of small automobile air conditioner.

| Type of machine | H1BK | |

| Maximum mass of workpiece | 10kg | |

| maximum;diameter of workpiece | φ360mm | |

| Distance between two bearing supports of the workpiece Shaft | 36~450mm | |

| Shaft diameter of workpiece | Standard roller support | φ5-φ22mm |

| Up to (optional) | φ50mm | |

| Diameter range in the driving position of belt | φ10-φ150mm | |

| Balancing speed for driven diameterφ100mm | 0~1500r/min | |

| Motor power | 0.18kW(AC) | |

| Min. achievable residual unbalance Emar/per planes | 0.05g.mm/kg | |

| Unbalance reduction ratio URR | URR95% | |

| Dimension(LxW×H) | 900×650×1220mm | |

| Type of machine | H2BK | |

| Maximum mass of workpiece | 40kg | |

| maximum;diameter of workpiece | φ800mm | |

| Distance between two bearing supports of the workpiece Shaft | 80-630mm | |

| Shaft diameter of workpiece | Standard roller support | φ8~φ50mm |

| Up to (optional) | Φ100mm | |

| Diameter range in the driving position of belt | φ20-φ200mm | |

| Balancing speed for driven diameterφ100mm | 0~1540r/min | |

| Motor power | 0.75kW | |

| Min. achievable residual unbalance Emar/per planes | 0.05g.mm/kg | |

| Unbalance reduction ratio URR | 95% | |

| Dimension(LxW×H) | 765×690×1190mm | |

| Type of machine | H3BU | |

| Maximum mass of workpiece | 200kg | |

| maximum;diameter of workpiece | Φ1260mm | |

| Distance between two bearing supports of the workpiece Shaft | 125~1320mm | |

| Shaft diameter of workpiece | Standard roller support | φ9-φ70mm |

| Up to (optional) | Φ140mm | |

| Diameter range in the driving position of belt | φ20-φ200mm | |

| Balancing speed for driven diameterφ100mm | 600/920/1200/1840r/min | |

| Motor power | 2.2KW | |

| Min. achievable residual unbalance Emar/per planes | 0.05g.mm/kg | |

| Unbalance reduction ratio URR | 95% | |

| Dimension(LxW×H) | 1500×1000×1300mm | |

This machine is especially suitable for balancing the rotors in medium-motor,air blower,diese,centrifuge,water pump,as well as the spindle in medium machine tool.

| Type of machine | H4U | |

| Max. mass of workpiece | 1000kg | |

| Max. diameter of workpiece | Φ 1600mm | |

| Distance between two bearing supports of the workpiece Shaft | Min. Distance between two supports | 70mm |

| Max. distance between driving flange and right bearing support | 2050mm | |

| Shaft diameter of workpiece | Standard roller support | Φ 12 ~ Φ 1 00mm |

| Up to (optional) | Φ200mm | |

Balancing speed (universal joint shaft driving) | 600/1250 r/min(with gear box) | |

| Motor power | 4kW | |

Rated torque of universal joint shaft | Accessories | 250N·m |

| Optional supply | 80N·m | |

| Min.achievable residual unbalance Emar/per planes | 0.25g.mm/kg | |

| Unbalance reduction ratio URR | 95% | |

| Dimension(LxWxH) | 3120 x 800 x 1420mm | |

| Type of machine | H6U | ||

| Max.mass of workpiece | 9000kg | ||

| Max.diameter of workpiece | Φ3000mm | ||

| Shaft diameter of workpiece | Standard | Φ40-φ180 | |

| Optional | φ180-φ320 | ||

| Distance between two bearing supports | Minimum distance | 400mm | |

| Maximum distance from driving flange to right support center | 2800mm | ||

| Balancing speed (r/min) | 230/390/685/1090/1680 | ||

| Motor power(D.C) | 30kW | ||

| Rated torque of universal join shaft | Standard | 2500N·m | |

| Optional | 700N·m | ||

| Min. achievable residual unbalance Emar/per planes | 0.25g.mm/kg | ||

| Unbalance reduction ratio URR | 95% | ||

| Dimension(LxWxH)(mm) | 4700×1640×2000mm | ||

| Type Specification | MBA-11S | MBB-11S | MBD-11S | MBC-18S |

| mass range of rotor (kg) | 5-100 | 5-100 | 5-100 | 6-160 |

| max. diameter (mm) | Φ 130 | Φ 130 | Φ 130 | Φ 150 |

| distance between left and right pedestal (mm) | three bearing max 2400 | max 2400 | max 3000 | max 3000 |

| machine bed length (mm) | 4430 | 4430 | 5030 | 5030 |

| range of shaft diameter (mm) | Φ40~Φ130 | Φ150 | ||

| balance speed (r/min) | 1500~4200 | 1500~3200 | ||

| motor power (kw) | 11 | 11 | 11 | 18 |

| max. initial unbalance (g·cm) | 1000 | 1000 | 1000 | 2000 |

| Min. achievable residual unbalance (g▪mm/kg) | 1 | 1 | 1 | 1 |

| measuring plane (piece) | 3 | 2 | 4 | 2 |

| dimension (L X W X H) (mm) | 4430 x 740 x 1 000 | 4430 x 740 x 1 000 | 5030 x 740 x 1 000 | 5030 x 740 x 1 050 |

| option | 1. welding machine-welds the balance piece on the shaft TN1 – 63/160 welding machine 2. printer-outputs test results | |||

| Type Main specification | YLD-10 | YLD- 30 | YLD-100 | YLS-10 | YLS- 30 | YLS-100 |

| Max. mass of rotors(including fixtures)(kg) | 10 | 30 | 100 | 10 | 30 | 100 |

| Max.dia of rotors with the safety cover(mm) | 400 | 1000 | 81000 | 400 | 850 | 850 |

| Max.dia of rotors with the safety cover(mm) | 400 | 600 | 600 | 400 | 540 | 540 |

| Balancing speed(r/min) | 1200 | 800 | 530 | 1200 | 800 | 530 |

| Motor power(kw) | 0.55 | 1.5 | 2.2 | 0.55 | 1.5 | 2.2 |

| Min. achievable residual unbalance (emar)(g▪mmkg) | 1 | 1 | 1 | 2 | 2 | 2 |

| Unbalance reduction ratio (URR) | ≥90% | ≥90% | ≥90% | ≥90% | ≥90% | ≥90% |

| Number of measuring planes | 1 | 1 | 1 | 2 | 2 | 2 |

| Type of measuring units | HW510 | HW510 | HW510 | HW220 | HW220 | HW220 |

| Dimension(L x W x H)(mm) | 1170 x 850 x 1650 | 1250 x 850 x 1650 | 1250 x 850 x 1650 | 900 x 850 x 1050 | 970 x 850 x 1200 | 970 x 850 x 1200 |

▪FOB

▪CIF

▪Package: Wooden case

Working Principle

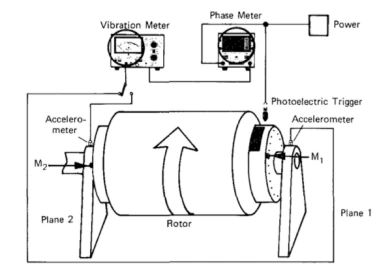

The working principle of a dynamic balancing machine is to measure the centrifugal force vibration signal generated by the uneven mass distribution of a rotating object (rotor), analyze the amplitude and phase to determine the size and position of the unbalance, and then achieve dynamic balance correction by increasing or decreasing the counterweight.

Core principle

The dynamic balancing machine is based on the theory of dynamic balance, and its workflow can be divided into the following steps:

Drive rotation: The motor drives the rotor to rotate at a constant speed. If there is uneven mass distribution, it will generate centrifugal force and cause vibration.

Signal acquisition: Sensors (such as piezoelectric sensors and photoelectric heads) capture vibration signals and speed signals, convert them into electrical signals, and transmit them to the electrical measurement system.

Data analysis: The electrical measurement system separates the power frequency component through Fourier transform, calculates the phase angle of the unbalance and the weight to be compensated.

Correction implementation: Based on the results, add or remove counterweights (such as balance blocks, milling notches) at specific positions on the rotor to achieve the allowable range of remaining unbalance.

Technical classification

Dynamic balancing machines can be divided into:

Support type:

Soft support balancing machine: The balancing speed is higher than the natural frequency of the rotor support system, and vibration displacement is detected.

Hard support balancing machine: The balancing speed is lower than the natural frequency, and the vibration force is directly detected.

Driving methods: belt driving, coupling driving, self driving (highest accuracy but limited applicability).

Application value

Dynamic balancing machines are widely used in fields such as automotive tires, motor rotors, centrifugal compressors, etc. Their main functions include:

Reduce vibration and noise, and improve operational stability.

Extend the lifespan of bearings and reduce energy consumption.

Ensure the safety of high-speed rotating equipment (such as preventing rotor fracture accidents).

History of Balancing Machine

Early development (late 19th century to 1940s)

In 1866, the German company Siemens invented the generator, marking the beginning of balancing technology. In 1907, Dr. Franz Lawaczek introduced balancing technology to Germany, and in 1915, Carl Schenck manufactured the first double-sided balancing machine. At this stage, mechanical balancing equipment is mainly used, usually measuring the resonance speed of the vibration system, which has large errors and complex operation.

Technological innovation stage (after the 1950s)

With the advancement of electronic technology, balancing machines gradually adopt electronic measurement technology, and planar separation circuit technology eliminates interference from the left and right calibration surfaces. After the 1950s, the application of piezoelectric sensor technology significantly improved the accuracy of balancing machines and gradually replaced traditional mechanical equipment.

Automation and Intelligence (after the 1970s)

The hard supported dynamic balancing machine achieves permanent calibration through static dimension setting, reducing the trouble of frequent dynamic adjustments. The application of microcomputer technology enables balancing machines to integrate optical, electrical, and mechanical technologies, and achieve automatic calibration functions, which are widely used in fields such as electric tools, fans, and motors.

Modern Applications (21st Century)

After 2000, integrated circuits and computer technology promoted the development of balancing machines towards higher precision and intelligence. Major global manufacturers such as Schenck and Shimadzu maintain their market leading position through technological innovation, while Chinese manufacturers have also achieved international level fully automatic balancing machines through independent research and development.