Automotive System

A symbol of industrial progress

Home>>Testing Rig>>Automotive System

Automotive System

Automotive system, as a symbol of industrial progress, it has shaped urban development, economies, and cultural lifestyles, though they also raise environmental concerns, prompting the shift toward sustainable alternatives like hybrid and hydrogen-powered vehicles.

SINOTEST help provide testing rigs for companies and research institute. With years of experience and support from numerous projects, more and more users are feeling the convenience and professionalism of our product.

AVAILABLE MODELS

Axle, Shaft testing rig

Absorber testing rig

Brake system, ECAS, Road simulation testing rig

Axle, Shaft testing rig

This series of machines can perform torsional fatigue tests on various shaft and rod components, such as torsional stiffness and strength tests, suitable for automotive transmission shafts, constant velocity universal joints, ball cages, half shafts, drive axle shells, etc.

Standard:

QC/T649 Automotive Steering Transmission Shaft Assembly Performance Requirements and Test Methods

QC/T29082 Technical Conditions and Bench Test Methods for Automobile Transmission Shaft Assembly

Torque range: 500~40000 N·m

Force measurement accuracy: Class 0.5~1

Load waveform: sine wave, square wave, etc.

The automobile stabilizer fatigue testing bench is used to test the fatigue life of the automobile stabilizer. It applies electro-hydraulic servo technology, uses a hydraulic system for loading, and has a dedicated servo controller to output instructions to the linear servo actuator to test the loading of the stabilizer.

This test rig can perform fatigue, stiffness, and strength tests on the stabilizer bar. When equipped with an environmental chamber, tests can be conducted in high and low temperature environments, as well as muddy water environments. The control system can also perform spectrum iteration for comprehensive performance testing

Standard:

JASO C617 Automotive Parts Stabilizer Bar

Single actuator test force: 25kN~100kN

Force measurement accuracy: Class 0.5~1

Load waveform: sine wave, square wave, path spectrum, etc

The Thrust rod fatigue loading test rig applies electro-hydraulic servo technology and uses a hydraulic system for loading. A dedicated servo controller can output commands to test the linear servo actuator. It is also possible to test the straight push rod, diagonal push rod, and Vshaped push rod by equipping them with different fixtures. Axial, radial, torsional, yaw, and coupled fatigue tests can also be conducted on the V-shaped push rod according to requirements.

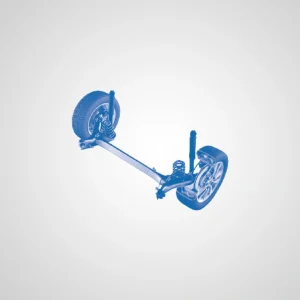

The Rear axle torsion beam test rig is used to test the rear axle torsion beam, shock absorber, and suspension spring assembly. Applying electro-hydraulic servo technology, hydraulic system loading is adopted, and a dedicated servo controller is used to output instructions to the linear servo actuator for experimentation.

This bench can be used for: parallel wheel jump force endurance test, lateral fatigue endurance test, 180 ° reverse displacement torsional fatigue test of left and right wheel cores, forward and backward braking fatigue endurance test, single side longitudinal force loading endurance test of wheel cores, single side vertical force fatigue test, static strength test, torsional stiffness test, etc.

Testing force: 25kN;

Force measurement accuracy: Class 0.5~1

Loading waveform: Sine wave, square wave, road spectrum, etc

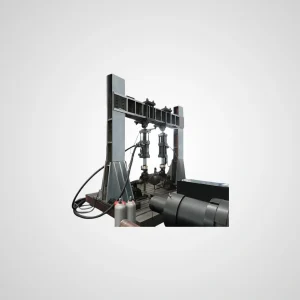

The Axle test rig can be equipped with 2 to 6 actuators to simulate the vertical, lateral, and longitudinal loads of the axle. The main components include: actuators, loading frames, work platforms, hydraulic systems, control systems, etc. The test rig is hydraulic loaded and suitable for fatigue performance testing of vehicle axles.

Standard: QC/T533 Commercial Vehicle Drive Axle Assembly

Test force: 200kN~1000kN;

Force testing accuracy: Class 0.5~1

Load waveform: sine wave, square wave, path spectrum, etc.

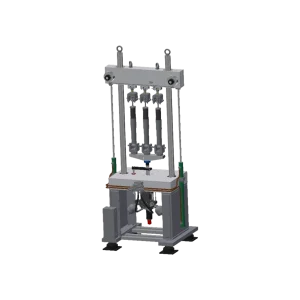

The Front subframe and loading arm test rig applies electro-hydraulic servo technology, uses a hydraulic system for loading, and conducts experiments by outputting instructions to the linear servo actuator through a dedicated servo controller.

This test rig can perform durability tests on the subframe and loading arm, driving impact tests, fatigue tests with lateral force in the same direction, static strength tests at the installation point, stiffness tests, X/Y impact tests on the swing arm, and static strength tests on the loading arm.

Testing force: 25kN~500kN

Force measurement accuracy: Class 0.5~1

Loading waveform: sine wave, square wave, path spetrum, etc.

The suspension spring fatigue test rig uses a hydraulic system to load and conducts experiments on the output commands of linear servo actuators through a dedicated servo controller. It can be used to test the fatigue life and stiffness of suspension springs. When equipped with an environmental chamber, experiments can be conducted in high and low temperature environments.

Air suspension axle joint test: Adopting a multi-channel configuration to achieve maximum restoration of installation conditions, multiple loading channels can be configured, and multiple testing methods are applicable. Strong load-bearing capacity, high accuracy, with functions such as phase coordination and amplitude coordination.

For example, it can be equipped with four channels (2 vertical, 1 horizontal, and 1 longitudinal). The vertical channel is used to simulate the wheel load state, and the lateral and longitudinal channels are used to simulate the vehicle’s bearing of lateral and longitudinal loads.

Test force: 10kN~100kN;

Force measurement accuracy: Class 0.5~1

Load waveform: sine wave, square wave, path spectrum, etc.

Absorber Testing Rig

As the main component of automobile suspension, the shock absorber is used to rapidly attenuate the relative vibration of the body and the wheels, suppress the wheel jump, and reduce the dynamic load of the wheels. Thereby improving the ride comfort and handling stability of the vehicle.

SINOTEST Customized Shock Absorber Testing Rig can help perform experiments on them, for example, static performance testing (power test, speed characteristics test) and fatigue life test (Durability test), temperature characteristic test, etc.

For now, SINOTEST has developed multiple testing platforms with workstations ranging from 1 to 5, which can be customized according to the actual needs of customers. This series of products is an essential testing equipment that is indispensable in multiple fields such as the automotive industry, construction industry, and industrial sector.

Technical features:

Maximum test speed: 3 m/s;

Maximum test load: 5 tons.

Can be equipped environment chamber

-300x267.webp)

Technical features:

Maximum test speed: 2 m/s;

The test can be carried out at position of 0°~90°.

Technical features:

Maximum test load: ±25KN;

Maximum test speed: 1 m/s;

Simulation of actual working conditions

Technical features:

Maximum test load: ±25KN;

Stroke: ±75mm;

3 test stations;

With air cooling;

Shock absorber rod test can be performed.

Technical features:

Maximum test speed: Upper- 0.7 m/s, Lower- 1.2 m/s;

Maximum load: ±30KN;

4 testing station;

Bidirectional movement;

With spray water cooling

Technical features:

Maximum test load: ±30KN;

Maximum test speed: 2 m/s;

5 test station;

Upper cylinder placing,

With door interlock,

One-way movement instead of two-way

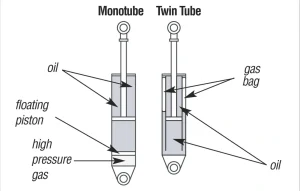

A shock absorber or damper is a mechanical or hydraulic device designed to absorb and damp shock impulses. It does this by converting the kinetic energy of the shock into another form of energy (typically heat) which is then dissipated. Most shock absorbers are a form of dashpot (a damper which resists motion via viscous friction).

In a vehicle, shock absorbers reduce the effect of traveling over rough ground, leading to improved ride quality and vehicle handling. While shock absorbers serve the purpose of limiting excessive suspension movement, their intended main purpose is to damp spring oscillations. Shock absorbers use valving of oil and gasses to absorb excess energy from the springs.

In Construction field, the most common type is a hydraulic shock absorber, which usually includes a piston, a cylinder, and an oil-filled chamber. The piston is connected to the piston rod, which extends into the cylinder and divides the cylinder into two parts.

As technology developed, other types of shock absorbers emerged, including gas and electric shock absorbers, that provided improved control and flexibility. Thus the testing for such important components is also indispensable.

Brake system, ECAS, Road simulation testing rig

The Automobile road simulation test rig uses electro-hydraulic servo technology and specialized static pressure supported servo actuators. Based on the vibration signals of the vehicle’s wheels during actual road or car testing, indoor random fatigue and vibration tests are conducted on the vehicle to analyze various functional indicators.

This device can perform vehicle reliability and durability enhancement tests, indoor simulation experiments of vehicle smoothness, dynamic performance simulation experiments of vehicle/component, and vehicle NVH testing.

Features:

- Suitable for ibooster and One box performance testing;

- Fully automatic vacuum exhaust, oil injection, and brake fluid filtration function;

- Optional spring load, cylinder load, and actual vehicle caliper load;

- Independently developed a dual range dedicated sensor with integrated surface switching to improve the measurement and control accuracy of small force values;

- The loading rod is equipped with a friction free guide device, which accurately

measures the starting force; - Equipped with diaphragm valves with high testing pressure and good sealing performance;

- The dedicated controller adopts ARM+FPGA processing chip, and the loading control mode includes force, displacement, pressure, and full closed-loop dual objective control (5kHZ), which can smoothly switch between each other;

- CAN communication can quickly match the actual vehicle DBC and Checksum through configuration wizards, and can quickly match the XCP protocol;

- Optional mechanical wheel speed simulation device and AK protocol simulation module;

- Can meet the environmental testing requirements of high, low, and humidity;

- Expandable HIL testing.

Features:

- Suitable for ibooster and One box durability testing, with multipleworkstations;

- Fully automatic vacuum exhaust, oil injection, and brake fluid filtration function;

- Optional spring load, cylinder load, and actual vehicle caliper load;

- It can be loaded using waveform combinations such as sine wave, triangular wave, square wave, oblique wave, etc;

- The dedicated controller adopts ARM+FPGA processing chip, and theloading controlmode includes force, displacement, pressure, and full closed-loop dual objective control (5kHZ), which can be smoothly switched between each other;

- CAN communication can quickly match the actual vehicle DBC and Checksum through the configuration wizard, and can quickly match the XCP protocol;

- Optional mechanical wheel speed simulation device and AK protocol simulation module;

- Can meet the requirements of high, low, and humidity environments

- Can meet the testing requirements of open and closed systems;

- Using a static pressure support actuator to simulate the load of the air spring, improving the following accuracy and response speed of the load during the inflation and deflation process;

- Can meet the performance testing requirements of samples with and without ECU;

- Integrated controller, using ARM+FPGA processing chip, meeting the XCP or DBC communication of CAN bus, can control the ECAS system for inflation and deflation, air spring pre-loading, expected load holding and following control, 5kHz/CH full closed-loop control frequency;

- CAN communication can quickly match the actual vehicle DBC and Checksum through the configuration wizard, and can quickly match the XCP protocol;

- Expandable HIL testing.