Introduction

Bearings, serving as the “joints” of the equipment manufacturing industry, are core foundational components for strategic and emerging industries such as aerospace, high-speed rail, and new energy vehicles. As the demand for domestic bearings in related industries shifts from “quantity” to “quality,” China’s bearing industry is imposing higher requirements for the performance testing of high-end bearings.

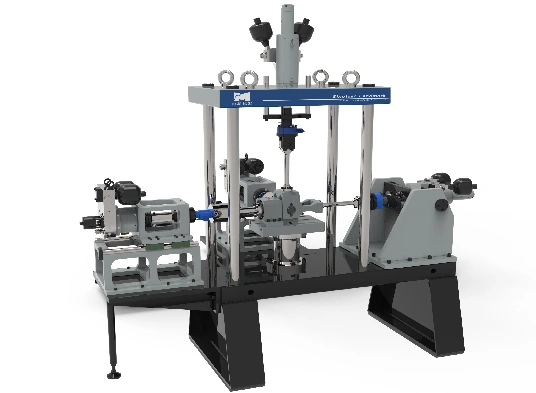

Our previous article shared a series of spherical plain bearing testing machines developed by SINOTEST Equipment Co., Ltd. to meet bearing performance testing needs (SINOTEST’s High-End Bearing Testing Machine Series Products Help the Bearing Industry Leap from ‘Quantity’ to ‘Quality’). This article continues by sharing the performance testing principles of this product series.

- Factors Affecting Spherical Plain Bearing Performance and Lifespan

To accurately measure the performance of spherical plain bearings, it is essential to understand the loading conditions and oscillation modes they endure under actual operating conditions. Based on lubrication methods, spherical plain bearings can be divided into self-lubricating and non-self-lubricating types. Among them, self-lubricating spherical plain bearings are widely used in aerospace, military equipment, and other fields due to their high load density and simple maintenance.

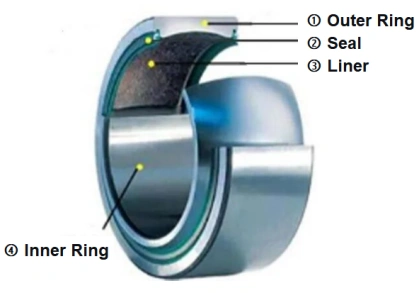

This article will analyze the structure and loading methods using “self-lubricating” spherical plain bearings as an example. A self-lubricating radial spherical plain bearing consists of four parts: ① Outer Ring, ② Seal, ③ Self-lubricating Liner, and ④ Inner Ring. Typically, the liner is bonded to the inner spherical surface of the outer ring. Its basic structure is shown in Figure 1.

Figure 1: Physical Diagram of Self-lubricating Spherical Plain Bearing

(I) Oscillation Conditions

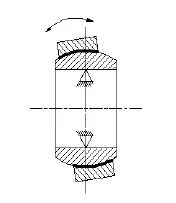

Factors affecting the wear life of spherical plain bearings also include the oscillation mode, oscillation frequency, and oscillation amplitude. The main oscillation modes of spherical plain bearings during operation include rotational oscillation, tilting oscillation, and compound oscillation combining both.

Figure 2: Spherical Plain Bearing Oscillation Modes

In actual operating conditions, the influence of the oscillation mode and the characteristics and magnitude of the applied load on the working performance of spherical plain bearings is as follows:

① Tilting and compound oscillation of the bearing can easily cause liner detachment;

② High pv values generated by high frequency and heavy loads can cause an increase in the friction temperature of the spherical plain bearing;

③ Heavy loads can also cause excessive deformation and failure of the bearing’s rigid materials.

(II) Loading Conditions

This type of bearing has closely fitted inner and outer rings (conforming contact) and primarily withstands radial and axial loads under oscillating motion.

The self-lubricating liner is generally made of non-metallic materials. In practical working environments, it is prone to different forms of damage and deformation under various loading methods such as alternating loads and impact loads. Therefore, the load-bearing capacity and service life of self-lubricating spherical plain bearings under alternating loads and impact loads are important indicators for evaluating their performance.

- Force Analysis of Spherical Plain Bearings in Actual Working Conditions

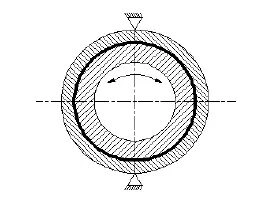

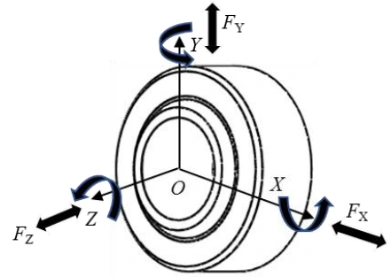

After understanding the oscillation modes and loading conditions of spherical plain bearings, we can establish a coordinate system O-XYZ based on the spherical centers of the inner and outer rings of the self-lubricating bearing to analyze the forces acting on the bearing under actual working conditions.

Figure 3: Schematic Diagram of Motion Modes and Load Application Directions

Using the fixed bearing outer ring (or inner ring) as the reference, the inner and outer rings can relatively reciprocate around the three coordinate axes: X, Y, and Z. During the actual operation of a self-lubricating spherical plain bearing, its actual motion state can be composed of the combination of rotations in these three directions. As shown in Figure 3, with the bearing inner ring fixed, the outer ring can relatively have forces FX, FY, FZ applied along the X, Y, and Z axes. In actual operation, the load applied to the self-lubricating spherical plain bearing can be derived from the combination of the loads in these three directions.

III. Load Application Methods for Spherical Plain Bearing Testing

From the above analysis of the motion forms and load directions of self-lubricating spherical plain bearings, it can be seen that the inner and outer rings of self-lubricating spherical plain bearings can relatively reciprocate around the three rotation axes X, Y, Z, and loads can be applied along the X, Y, Z directions. Therefore, the loading methods can be divided into unidirectional loading, bidirectional loading, and multi-directional loading.

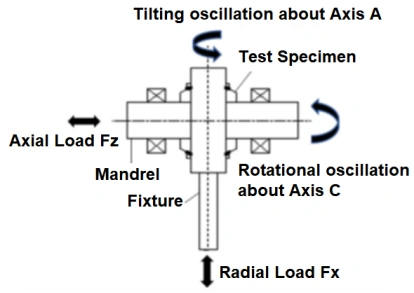

SINOTEST considers the load state of self-lubricating spherical plain bearings under actual working conditions, dividing the loads borne during performance testing into several modules: the Radial Loading Module, Axial Loading Module, Tilting Oscillation Module, and Rotational Oscillation Module.

Figure 4: Schematic Diagram of Each Loading Module

Among them, the radial and axial loading modules simulate the loads experienced by the self-lubricating spherical plain bearing under actual working conditions, while the tilting and rotational oscillation modules simulate the motion modes of the self-lubricating spherical plain bearing under actual working conditions, fully restoring the force application method on the self-lubricating spherical plain bearing, thereby enabling comprehensive and accurate performance testing.

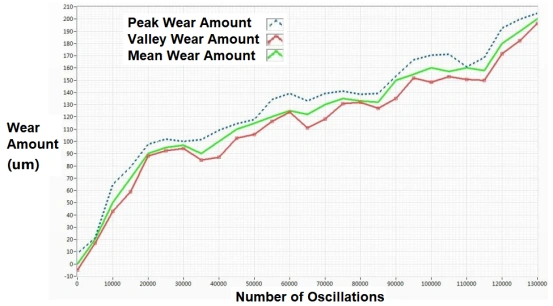

In actual test cases, a compound oscillation spherical plain bearing life testing machine developed using the above method was used to repeatedly test the tribological performance of self-lubricating radial spherical plain bearings under different oscillation modes. The test conditions were: room temperature; test duration approximately 18 hours (approximately 130,000 oscillations); radial load 10 kN; oscillation angle ±5°; oscillation frequency 2 Hz. Figure 5 shows the relationship curve between the number of oscillations and the wear amount of the spherical plain bearing during the test.

Figure 5: Relationship Curve Between Number of Oscillations and Wear Amount

From Figure 5, it can be seen that the wear amount of the spherical plain bearing with increasing continuous rotational oscillations can be roughly divided into three stages: In the initial stage, the self-lubricating bearing is in the running-in process, and the wear amount increases rapidly; in the stable stage, the wear of the bearing friction pair surface is mainly dominated by the wear of the transfer film, and the wear amount increases steadily; in the rapid wear stage, the liner is worn through, and the wear amount increases sharply, which is basically consistent with the wear situation of self-lubricating spherical plain bearings under actual working conditions.

- Related Products

The series of spherical plain bearing testing machines developed based on the principles described in this article, while highly restoring the actual working conditions of the samples, adopt dedicated acquisition control systems and integrated loading systems specifically for spherical plain bearing testing, significantly shortening the load chain, and featuring characteristics such as high stiffness and high frequency response.

This series of testing machines can be loaded according to standard waveforms or according to a certain wave spectrum. They can perform both alternating load tests and fatigue tests. The testing conditions can basically cover all current spherical plain bearing products on the market.