Non-Metallic Testing Machines

Non-Metallic Testing Machines

Automatic notch machine

Single sample quantity: 1-24 pieces

Tool length: 50mm

Tool material: Hard alloy

Spindle speed: 1250r/min

Automatic feed speed: 0~100mm/min, adjustable

Compliant with: ISO179, ISO180, GB/T1043, GB/T1843, GB/T8814

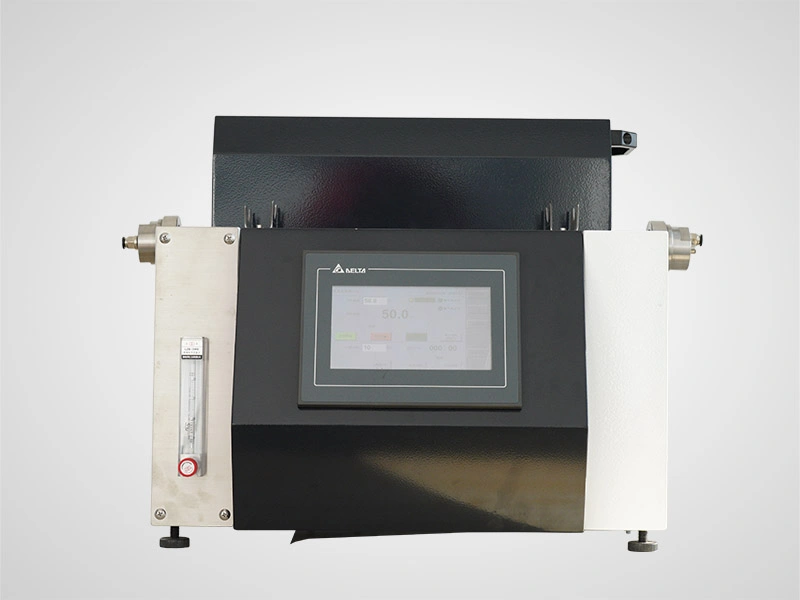

Automatic valve leakage detection testing machine

Touch screen operation;

Valve diameter: DN10~DN100;

Test fixture: flange type: 10-100, internal thread type: 1/2 “~4”;

Pressure range: 0-6MPa;

Penetration rate: 0-10ml;

Minimum division value: 0.1ml;

Compliant with standard: GB/T13927

Carbon black content tester

Temperature range: Room temperature~1000 ℃

Display mode: 7-inch touch screen

Quartz tube size: 40mm * 600mm

Furnace size: 40mm * 420mm

Heating element: High temperature alloy resistance wire

Heating zone length: 300mm

Temperature control method: Multiple segmented heating programs can be set, and the temperature setting segments are automatically memorized

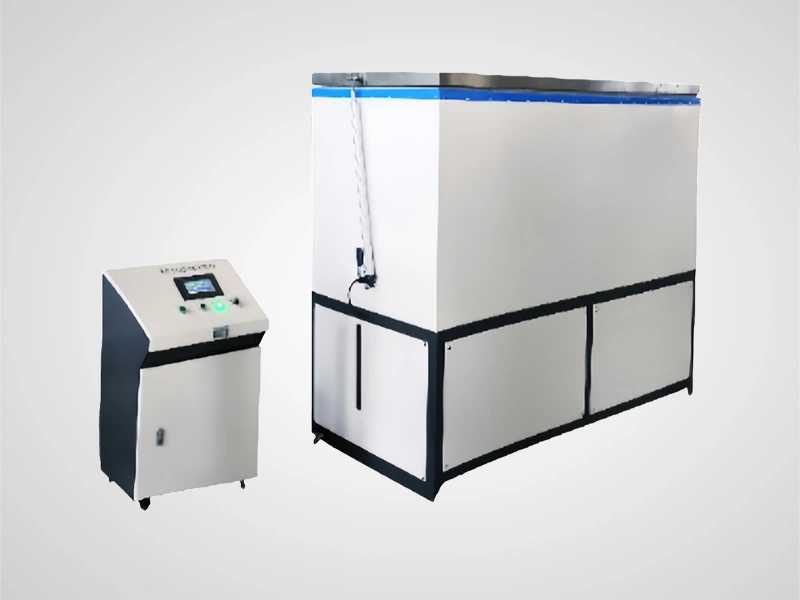

Pressure Resistant & Burst Testing Machine

The pipe pressure resistant & burst testing machine is suitable for determining the instantaneous hydraulic burst performance and long-term constant pressure resistance of various fluid transport plastic pipes. It is an essential testing instrument for research institutes, quality inspection departments, and pipe manufacturers.

Carbon black dispersion detection system

10x large field eyepiece, and infinite working distance objective lens 4X 10X 40X 100X (optional)

Satisfy customers’ observation needs at different magnifications

Adopting a 1/1.8-inch 10 million high-definition camera

Pixel size 2.4 μ m × 2.4 μ m, resolution 3072 × 2048, high-definition and high dynamic

Compliant with standards: GB/T18553-2002, GB/T 18251-2019, ISO 18553-2002

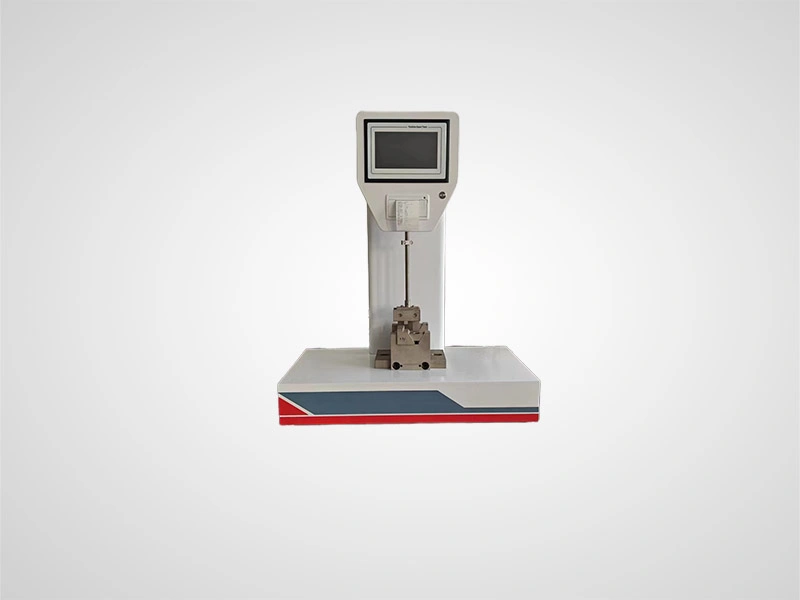

Charpy Pendulum Impact Tester (Digital Display) for Pipe

LCD display, touch screen operation;

Comes with one hammer as standard, used for impact testing of pipes with specifications of Φ 16 and Φ 20 (also for punching plates with specifications of Φ 25 and above).

The impact energy is 7.5/15J.

Meet the standards IS0179、GB/T1043、GB/T2611、GB/21189、GB/T18743.1/18743.2-2022

Dimensions: L × W × H=700 * 400 * 850mm

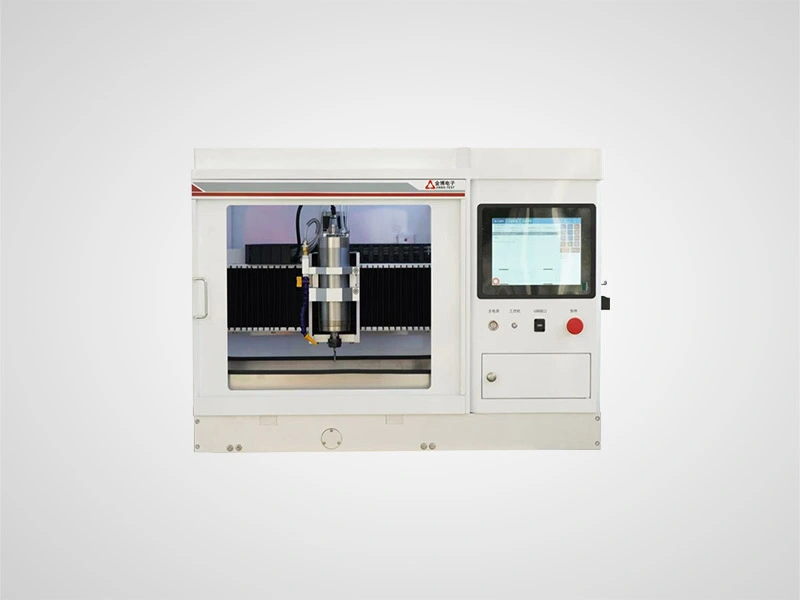

CNC Universal notch machine

Maximum processing length: 400mm

Maximum processing width: 300mm

Maximum processing thickness: 50mm

Spindle motor speed: 24000r/min

Precision resolution: 0.003mm

Cutting speed: 100~3000mm/min, adjustable.

Host size: L * W * H=971 × 640 × 622mm

Weight: 65kg

Compliant with standards: GB/T1040, GB/T1043, GB/T1843, GB/T8004.2, GB/T1633, GB/T1634

Constant temperature Water chamber

Composed of a chamber, a circulation system, and a temperature control system;

Temperature control range: 20-95 ℃;

3-channel configuration.

Internal dimensions:L*W*H=600*400*800mm

External dimensions: L*W*H=1200*700*1170mm

Place the pipe sample upright.

Temperature control accuracy: ± 0.5 ℃, heating power: 9KW.

Configurable cooling system: 0.7P refrigeration machine and corresponding refrigeration pipelines.

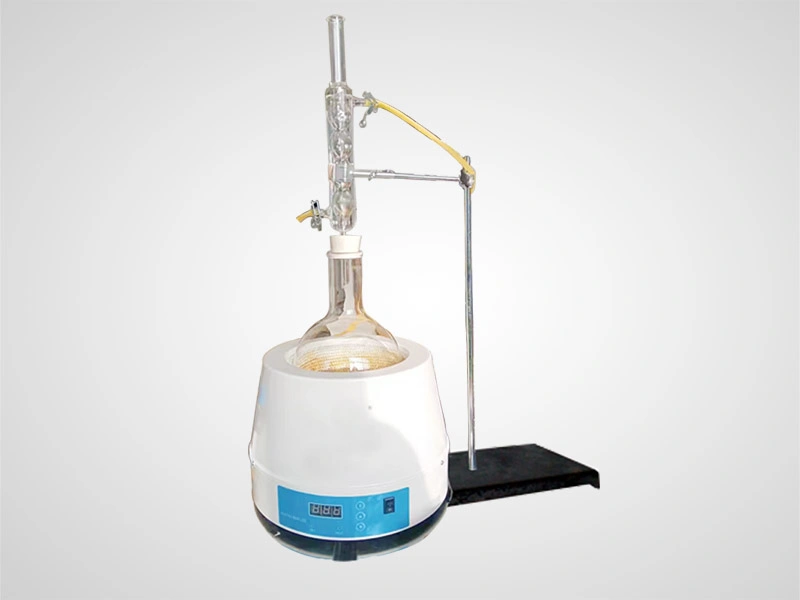

Crosslinking degree tester

Electronic temperature regulating electric heating sleeve, capable of producing 6 samples simultaneously;

Specification: 2000ml;

Power supply voltage: 220V;

Maximum operating temperature: 0-380 ℃;

Heating power: 500W;

Standard: GB/T18474

Users need to bring their own xylene solvent, antioxidant, one ten thousandth balance, and oven.

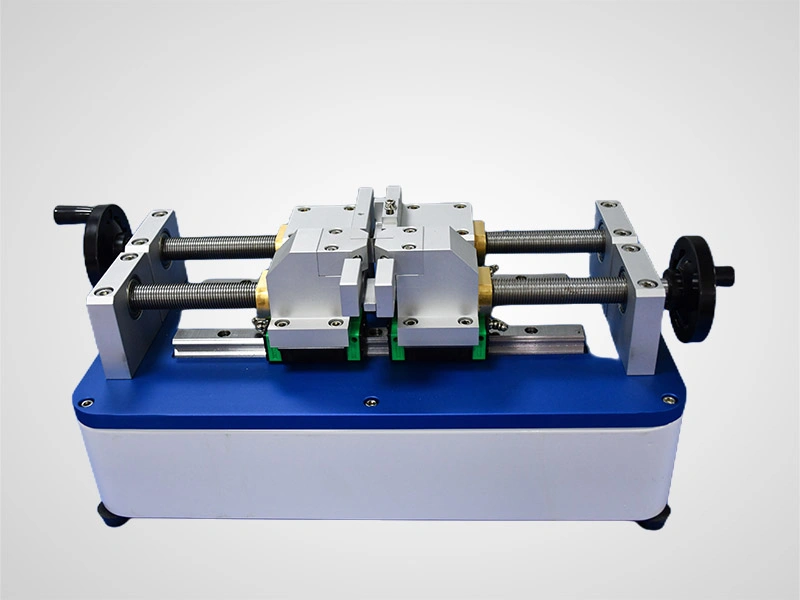

Double notch machine

Cutting blade thickness: 0.23 ± 0.03mm

Cutting end angle of the cutter: 14 °± 2 °

Remaining thickness of sample: adjustable

Clamping width adjustment range: 1-25mm

Cutting accuracy: ± 0.05mm

Dimensions: L * W * H=480 * 23 * 250mm

Compliant with: GB/T 18743.1, GB/T 18743.2, GB/T 21461.2

Drop hammer impact testing machine

10 inch touch screen operation;

Maximum impact energy: 300J;

Equipped with micro printing function;

Maximum impact height: 2000mm;

Hammer head: one D25 and one D90 each.

Compliant with standards: JB/T9389, GB/T 14152, GB/T10002.1, GB/T13664, GB/T 16800

Dimensions: L * W * H=1100 * 570 * 3410mm

Voltage: 220V/1000W

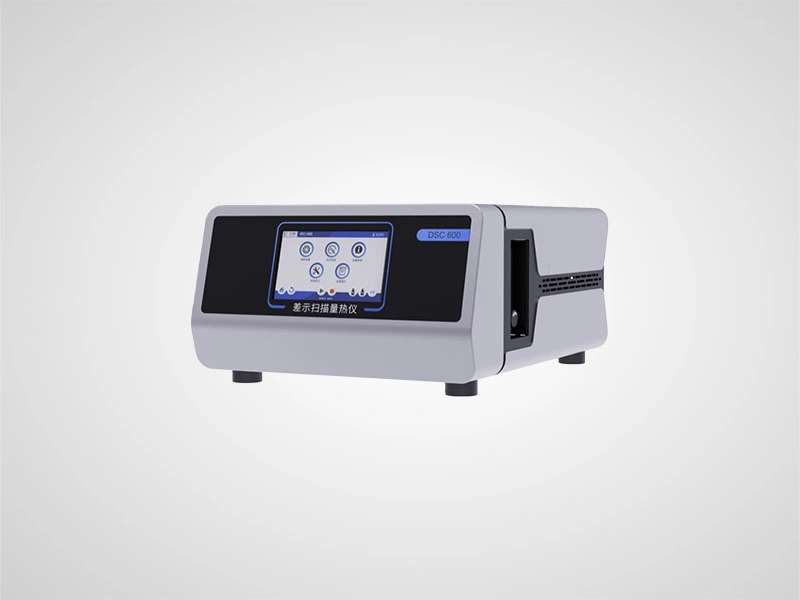

DSC tester

The integrated design of the whole machine reduces signal loss and interference, greatly improves signal sensitivity and resolution, and can obtain a more stable baseline.

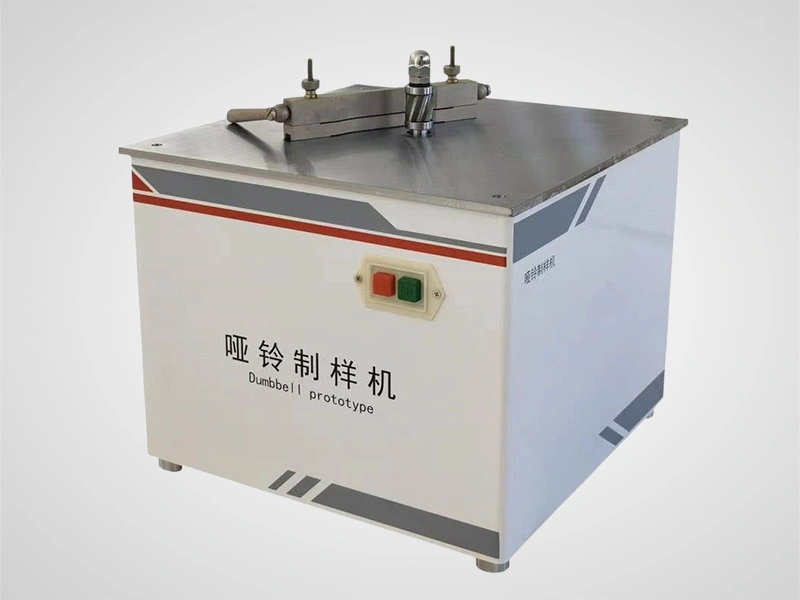

Dumbbell notch machine

Manual type, containing 1 Type I template

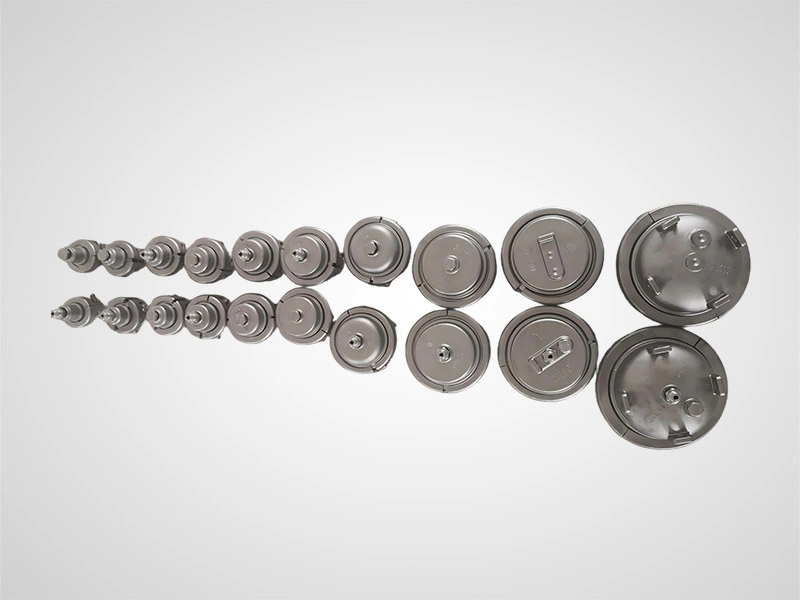

Fixture Type A

Used with Pressure resistant & Burst testing machine;

304 stainless steel material, diverse specifications, compatible with GB standard and ASTM standard

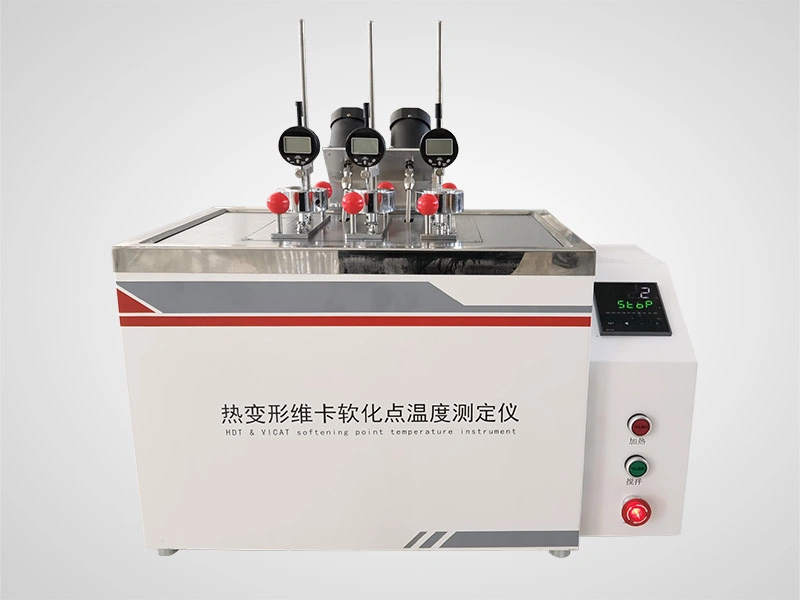

Hot deformation/Vicat softening point temperature tester

Equipped with a desktop computer and a 7-inch color LCD touch screen for operation;

Dial indicator display;

Equipped with a micro printer;

The standard configuration includes 3 test racks, which can be manually lifted; After the experiment is completed, it will automatically stop and calculate the test data.

Meet the standards ISO75-1974、ISO306-1974、GB1633-79、GB1634-79、GB/T 8802 Dimensions: L * W * H=830 * 600 * 640mm

Low temperature freeze chamber

Temperature range: -20℃~Room temperature

Dimensions: L * W * H=820 * 530 * 810mm

Internal dimensions: L * W * H=690 * 350 * 640mm

Capacity: 160L

Melt Flow Index tester

Temperature control range: 120 ℃~450 ℃, with fast heating rate and minimal overshoot

Temperature display indication error: ≤± 0.2 ℃, high temperature control accuracy

Temperature display resolution: 0.1 ℃

Recovery time: ≤ 4 minutes, can quickly recover to a constant temperature state after filling

Display mode: touch screen display, operation

Measurement method: Quality method

Test bench for plumbing valves

3-way configuration, valve diameter: DN10~DN100;

Test fixture: flange type 10-100, internal thread type 1/2 “~4”;

Pressure range: 0-6MPa;

Penetration rate: 0~10ml;

Minimum division value: 0.1ml;

Pressure input: Pressure resistant & burst testing machine.

Compliant with standard: GB/T13927

Pipe Opacity Tester

Measures opacity of plastic pipes/fittings.

Standards: GB/T 18742, GB/T 21300

Key Specs:

Range: 0-2%

Accuracy: <0.05%

Light Source: 550±5 nm

Sample: φ20-40 mm pipes

Power: 220V, 120 W

Dimensions: 280×330×480 mm

Valve Pressure Test Machines

Shell strength, backseat, and sealing performance tests.

Standards: GB/T 13927, GB 4581, GB/T 12232

Key Specs:

Model: FM-150J(Vertical), FM-300W(Horizontal)

Test Pressure: Hydraulic: 0-10 MPa, Pneumatic: 0-0.7 MPa

Pressure Sensor Accuracy: 0.5% F.S., Resolution: 0.1 MPa

Maximum Oil Circuit Pressure: 25 MPa

Hydraulic Oil: No. 46 Hydraulic Oil

Test Medium: Room Temperature Water

Valve Specimen Nominal Diameter:

DN15-DN150, Max. Valve Spacing: 60-600 mm, Flange Size: 80-350 mm

DN80-DN300, Clamping Valve Spacing: 200-1000 mm, Flange Size: 155-550 mm

Power Supply: 380V, Three-phase Five-wire System, Power: 8 kW

Required Air Supply Pressure: 0.7 MPa

Building Materials Freeze-Thaw Test Bench

Freeze-thaw resistance testing for external wall insulation systems, various building materials, concrete, bricks, and hollow concrete blocks.

Standards: GB/T 50082, GB/T 11968, GB/T 11973, GB/T 2542, JG 149, JG 158, JG/T 243

Key Specs:

Temperatures: Water tank: Ambient ~ 50°C (±2°C); Test chamber: Ambient ~ -30°C (±0.5°C).

Cooling Rate: Chamber cools from 25°C to below -25°C in 20-50 min (empty).

Capacity: Up to 10 blocks (390×190×190 mm) or 32 groups of concrete specimens (100×100×100 mm).

Chamber Volume: 1100 × 570 × 500 mm.

Power: 380V, 9 kW.

Dimensions: 2085 × 850 × 1145 mm; Weight: 380 kg.

Concrete Rapid Freeze-Thaw Test Bench

Testing concrete using the rapid freeze-thaw method.

Standards: GB/T 50082, JG/T 243

Key Specs:

Cycle: 2-4 hours per cycle (thawing ≥ 1/4 of total time). Transition time < 10 min.

Specimen Temp.: Freezing end: -17±2°C (center); Thawing end: +8±2°C (center). Max. temp. difference (inside-outside) < 28°C.

Temp. Accuracy: ±0.5°C.

Power: 380V, 17 kW (max. operational 11 kW).

Dimensions:

Test Chamber: 1135 × 1200 × 1260 mm

Control Cabinet: 600 × 450 × 1600 mm

Refrigeration Unit: 1700 × 1130 × 1720 mm (outdoor)

Weight: 800 kg.