Energy System

Home>>Testing Rig>>Energy System

Energy System

The use of clean energy has been one of the most important topics of social concern and discussion in recent years, such as wind energy, solar energy, hydro energy, etc.

SINOTEST responds to the forefront of energy systems and provides a comprehensive testing system for a range of components in wind power generation systems. With the help of our testing rig, more and more countries are implementing and improving wind energy projects, bringing more convenience to people and ensuring the safe operation of energy systems.

AVAILABLE MODELS

Blade Testing Rig

Pitch Mechanical Testing Rig

Bearing component Testing Rig

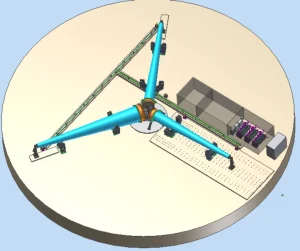

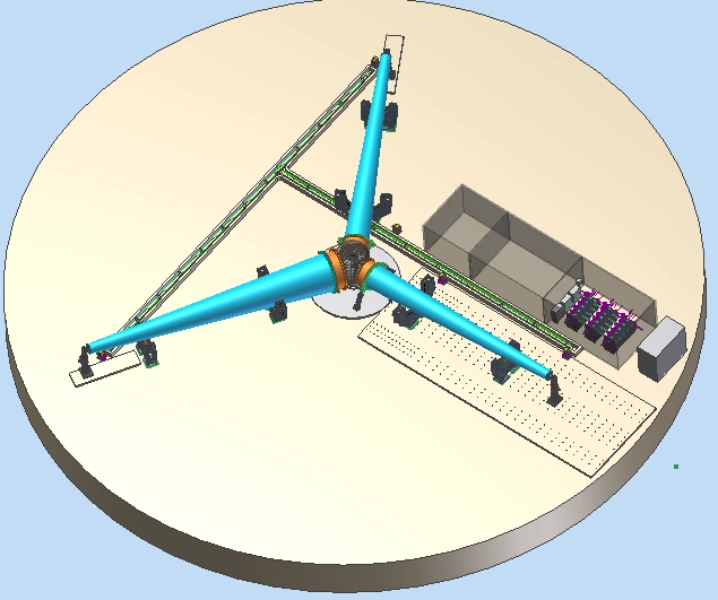

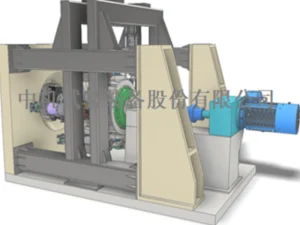

Blade Testing Rig

The blade testing of wind power equipment is the core link to ensure the safe operation and service life of blades, mainly focusing on three dimensions: structural strength, operational performance, and environmental adaptability. SINOTEST Fatigue Testing Rig helps with Fatigue Test: Apply millions level cyclic loads to simulate the alternating stress of blades during 20-25 years of operation. This type of test is a key test to determine the service life of blades, and it needs to last for several weeks to months.

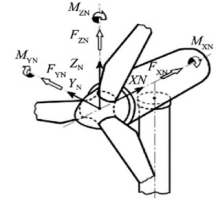

Pitch Mechanical Testing Rig

Pitch control is a core technology for Wind power equipment to control blades and ensure safe and stable power generation. In a word, pitch control is the process of adjusting the angle between wind turbine blades and the wind (known as the pitch angle) to control the amount of wind energy captured and the rotational speed of the wind turbine.

Core Functions of Pitch Control

By primarily adjusting the pitch angle, the pitch control system fulfills three core functions, which directly affect the efficiency and safety of the wind turbine.

- Maximizing power generation efficiency: When wind speed is low, the pitch control system adjusts the pitch angle to the optimal position (usually close to 0°). This allows the blades to face the wind with the largest possible area, capture the maximum wind energy, and ensure optimal power output.

- Limiting wind turbine speed: When wind speed is too high (exceeding the rated wind speed), the pitch control system increases the pitch angle. This reduces the wind-facing area of the blades, decreases wind energy absorption, and prevents component damage due to overloading caused by excessive rotational speed of the wind turbine.

- Enabling emergency shutdown: In case of extreme weather (such as typhoons) or equipment failures, the pitch control system quickly adjusts the pitch angle to 90° (feathering state). At this point, the blades barely face the wind, and the wind turbine stops rotating rapidly under the effect of wind resistance, ensuring the safety of the equipment.

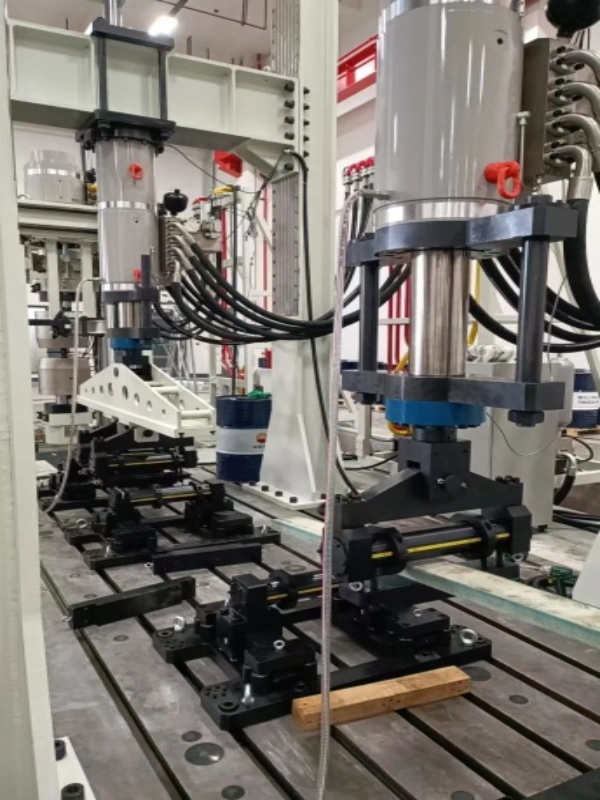

SINOTEST Pitch Mechanical Testing Rig adopts electro-hydraulic servo loading technology, combined with a high-frequency response electro-hydraulic servo actuator system and an advanced controller. It can conduct various tests, including linear loading test, planar loading test and torque loading test of pitch bearings. According to the design requirements, it can perform two types of tests for pitch bearings: linear loading test and planar loading test.

.

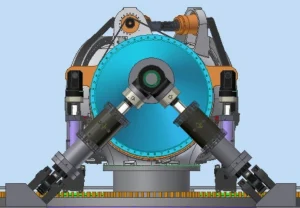

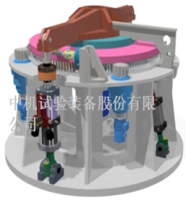

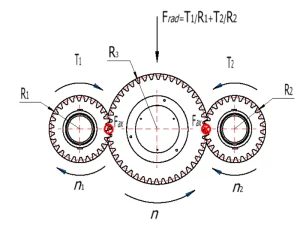

Bearing component Testing Rig

Application:

Conduct scaling tests on various spindle bearings through simulation of wind loads.

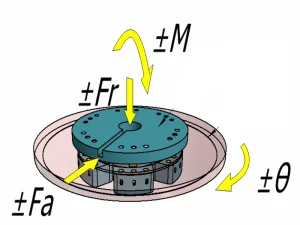

Parameters:

Axial (Fx) load: 1000kN

Radial (Fy) load: 20kN

Radial (Fz) load: 1300kN

Pitching moment (My): 350kNm

Yawing moment (Mz): 250kNm

Driving speed: 27~270rpm

Application:

Conduct scaling tests on various yawing bearings by simulating wind loads.

Parameters:

Axial load: 2200kN

Radial load: 200kN

Bending moment: 1600kNm

Driving speed: 0.98rpm

Application:

Conduct scaling tests on various gearbox shaft bearings through load simulation.

Parameters:

Radial load: 6000kN

Overturning moment: 650kNm

Bending moment: 650kNm

Drive speed: 0.2~200rpm

.webp)