Furniture Testing Equipment

INICIO>>Banco de Pruebas>>Furniture Testing Equipment

Furniture Testing Equipment

This comprehensive range of furniture testing equipment is designed for quality control, research and development, and certification purposes within the furniture manufacturing industry. It enables rigorous mechanical and durability assessments to ensure product safety, reliability, and compliance with established performance benchmarks.

Application Industry

Furniture Manufacturing (Residential, Office, and Commercial)

Furniture Quality Testing Laboratories

Certification and Standards Institutions

Research & Development Centers

Test Workpieces / Specimens

The equipment suite tests a wide variety of furniture components and finished products:

Seating: Chairs (including office/swivel chairs), stools, sofas, and their sub-components (seats, backs, armrests, swivel mechanisms, and casters).

Case Goods: Cabinets, storage units, and tables.

Bedding: Mattresses and mattress edges.

Specific Components: Chair casters, cabinet casters, seat swivel mechanisms, and sofa arm/back rest assemblies.

Applicable Standards

GB/T 10357.1, GB/T 10357.2: Stability tests for chairs and stools., GB/T 10357.3, GB/T 10357.4 & GB/T 10357.5, GB/T 2280, QB/T 1952.1 & QB/T 1952.2.

MODELOS DISPONIBLES

Chair & Stool Testing Equipment

This category focuses on the safety, strength, and durability of various seating products, including office chairs, stools, and their critical components.

Cabinet & Storage Testing Equipment

This group evaluates the structural integrity, durability, and mobility of cabinets, wardrobes, and other storage units under simulated use conditions.

Mattress & Sofa Testing Equipment

Designed for upholstered furniture, this category tests the long-term comfort, support, and edge integrity of mattresses and sofas.

Multi-Purpose & Drop Testing Equipment

This category covers versatile equipment capable of testing a wide range of furniture types through standardized impact and drop tests.

Detailed Information

Purpose: Tests the strength of chairs and stools.

Standards: GB/T 10357.3

Key Specs:

Seat Impact: 200mm diameter impactor, mass 17±0.1 kg, adjustable heights.

Back/Arm Impact: 6.5 kg pendulum.

Control Accuracy: ±1% to ±5% depending on parameter.

Power: 220V AC.

Dimensions: 1200×2400×2500 mm; Weight: 650 kg.

Purpose: Tests the durability of chair/stool armrests.

Standards: GB/T 10357.3

Key Specs:

Power: 220V AC, 400W.

Dimensions: 1200×1200×2200 mm; Weight: 270 kg.

Purpose: Tests the strength and durability of cabinets.

Standards: GB/T 10357.4, GB/T 10357.5

Key Specs:

Force Range: 4-2000 N.

Power: 220V AC, 700W.

Dimensions: 2400×2400×2400 mm; Weight: 820 kg.

Purpose: Reciprocating wear test for cabinet casters.

Standards: GB/T 10357.5

Key Specs:

Specimen: Up to 1200×500×1600 mm.

Force Accuracy: ±3%.

Power: 220V AC, 0.2kW.

Dimensions: 2400×1500×1800 mm; Weight: 350 kg.

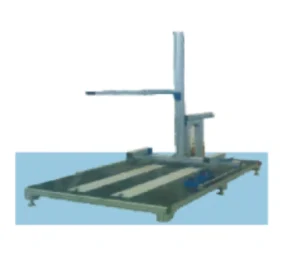

Purpose: Drop test for chairs, stools, cabinets, and tables.

Standards: GB/T 10357.1, GB/T 10357.3, GB/T 10357.5

Key Specs:

Specimen Range: Height ≤1400 mm, Width ≤650 mm.

Control Accuracy: ±1 mm.

Power: 220V AC, 1 kW.

Dimensions: 2400×2400×2400 mm; Weight: 340 kg.

Purpose: Wear testing for swivel chair casters.

Standards: GB/T 2280

Key Specs:

Force Accuracy: ±5%.

Power: 220V AC, 0.5 kW.

Dimensions: 1000×1200×2400 mm; Weight: 350 kg.

Purpose: Impact and impact durability testing for office chair seats.

Standards: GB/T 2280

Key Specs:

Power: 220V AC, 2 kW.

Dimensions: 1200×1200×2700 mm; Weight: 270 kg.

Purpose: Elasticity and durability testing for sofas.

Standards: QB/T 1952.1

Key Specs:

Loads: Armrest 250N, Backrest 300N.

Speed: 20-25 cycles/min.

Force Accuracy: ±3%.

Power: 220V AC, 4.7 kW.

Dimensions: 2400×2000×2400 mm; Weight: 700 kg.

Purpose: Mechanical performance testing for mattresses (load deflection, durability).

Standards: QB/T 1952.2

Key Specs:

Force Range: 4-2000 N.

Power: 220V AC, 3.7 kW.

Dimensions: 3000×2400×2520 mm; Weight: 800 kg.

Purpose: Edge durability testing for mattresses.

Standards: QB/T 1952.2

Key Specs:

Force Range: 4-2000 N.

Power: 220V AC, 0.9 kW.

Footprint: 2400×2000 mm; Weight: 600 kg.

Working Principles

Furniture testing equipment operates on the principle of accelerated life and performance simulation. Its core function is to replicate, in a controlled and accelerated manner, the years of stress, strain, and repetitive use that furniture endures in real-world environments, in order to predict failure points and verify compliance with safety and durability standards. The working principles can be categorized by the primary mechanical actions they simulate:

Cyclic Loading & Fatigue Simulation

An actuator (pneumatic, hydraulic, or servo-electric) applies a repeated force or displacement to a component for thousands of cycles. Sofa/Chair Durability Testers repeatedly compress seats and backs. Cabinet Testers open/close doors and drawers. Seat Swivel Testers rotate the seat mechanism. This simulates long-term use to identify material fatigue, joint failure, or mechanism wear.

Impact & Shock Testing

A mass (free-falling or pendulum-driven) strikes the test specimen with a specified kinetic energy. Drop Testers release furniture from a set height onto a floor. Seat/Back Impact Testers use a pendulum or falling weight to simulate sudden sitting or leaning forces. This evaluates structural integrity and resistance to sudden shocks.

Wear & Abrasion Simulation

A test specimen is subjected to continuous, repetitive motion against a surface or under load. Caster Wear Testers roll casters in a fixed path for thousands of cycles. Reciprocating Testers move cabinet drawers or units back and forth. This assesses the wear resistance of moving parts and finishes.

Stability & Static Load Testing

A controlled, incremental force is applied to a structure, or it is tilted to a critical angle, to measure its point of instability or deflection. Stability Testers apply loads to chair backs or seats on an inclined platform. Mattress Load Testers apply and hold pressure to measure sag and permanent set. This verifies safety margins and load-bearing capacity.

Control & Measurement System

The unified principle across all equipment is the closed-loop control and data acquisition system. Sensors (load cells, encoders, displacement transducers) continuously measure force, position, and cycles. A controller (PLC or computer) compares these readings to preset test parameters, adjusts the actuators in real-time for accuracy, and logs all data. This ensures tests are repeatable, precise, and generate objective, quantifiable results for compliance reporting.

Development History of Furniture Testing Equipment

- Mechanical & Standardized Beginnings

Following the establishment of formal testing standards (e.g., GB/T, ISO), early equipment emerged as purely mechanical simulators. These devices—basic impact pendulums, lever-loaded frames, and drop platforms—introduced repeatable, quantifiable methods to assess strength and durability for chairs, cabinets, and tables.

- Automation & Digital Integration

The adoption of programmable logic controllers (PLCs) and servo motors brought precision and consistency. Testing for seating (swivels, casters), cabinets, and upholstery (sofas, mattresses) transitioned from manual operation to automated cycles with digital control and data logging, enabling complex multi-station durability tests.

- Intelligent & Connected Systems

Current equipment is defined by computerized intelligence and integration. Touch-screen interfaces, modular fixtures, and sophisticated software allow for simulating real-world usage patterns across all categories—from advanced caster wear tests to mattress rolling durability. Data is centralized for comprehensive analysis and streamlined compliance reporting, supporting global quality assurance.