Electrical & Cable Testing System

INICIO>>Banco de Pruebas>>Electrical & Cable Testing System

Electrical & Cable Testing System

It is designed for the rigorous quality control, safety verification, and performance validation of electrical accessories and cable products. It simulates a wide range of conditions—including environmental (damp heat, low temperature), mechanical (impact, withdrawal force, endurance cycling), thermal (temperature rise, glow-wire), electrical (load, breaking capacity), and fire hazards (flame spread, heat release, smoke density)—to ensure components meet stringent international and national standards for reliability, durability, and safety.

Application Industry

Electrical Manufacturing: Manufacturers of plugs, sockets, switches, circuit breakers, and other wiring accessories.

Wire & Cable Industry: Producers of insulated wires, power cables, communication cables, and bunched cable installations.

Consumer Electronics & Appliances: For testing components and connectors used in final products.

Building & Construction: Ensuring the safety of electrical installation materials used in residential, commercial, and industrial settings.

Quality Inspection & Certification Labs: Third-party laboratories and internal QA departments performing type tests and routine inspections.

Test Workpieces / Specimens

Electrical Accessories: Plugs, sockets (receptacles), switches, circuit breakers (MCBs, RCDs), insulated pins, and connectors.

Cable & Wire Samples: Single insulated wires/cables, vertically mounted bunched cables, cable trays/ladders, and fire-resistant cables.

Insulating Materials: Material samples used in electrical components for ignitability and thermal properties.

Applicable Standards

GB 2099.1 / GB 16915.1: General safety requirements for plugs, sockets, and switches.

GB/T 2423.3: Basic environmental testing procedures – Damp heat test.

GB/T 5169.10-11 (Glow-wire): Fire hazard testing for electrotechnical products.

GB/T 18380 series (IEC 60332): Flame spread testing for single wires and bunched cables.

GB/T 19216 series (IEC 60331): Fire resistance testing for electric cables.

GB/T 17650.1/.2 & GB/T 17651.1/.2: Tests for halogen acid gas emission, pH, conductivity, and smoke density from burning cables.

GB 10963.1/.2 & GB 16917.1: Standards for circuit-breakers (MCBs) and residual current devices (RCDs).

GB/T 16842 / GB 4028 (IEC 60529): Protection against electric shock and ingress protection (IP code) testing.

GB/T 31248: Test for heat release and flame spread of bunched cables.

MODELOS DISPONIBLES

Mechanical & Electrical Safety Testers

This category evaluates the physical integrity, connection reliability, and basic electrical safety of components. These testers measure plug retention force, socket contact grip, and impact resistance of switches. They also verify the effectiveness of protective barriers against accidental access to live parts, ensuring fundamental mechanical and electrical safety compliance.

Environmental, Endurance & Thermal Testers

This category simulates long-term usage, harsh environments, and thermal stress to assess product reliability and performance under such conditions. Equipment in this group tests performance after cold shock, resistance to damp heat, material behavior under heat and pressure, and mechanical/electrical endurance through high-cycle operation. It also measures operational temperature rise and material ignitability to evaluate overall durability and thermal safety.

Electrical Load & Performance Simulators

This category provides programmable power sources to validate component functionality under various circuit conditions. As the core electrical supply and loading units, these simulators create precise and stable test conditions (variable current, voltage, power factor) required for endurance, breaking capacity, and temperature rise tests on switches, sockets, and circuit breakers.

Cable Fire Performance & Hazard Test Chambers

This comprehensive suite evaluates all critical fire safety aspects of cables, from flame spread to smoke toxicity. This is a complete system for assessing cable fire safety. It tests flame propagation of single and bunched cables, measures smoke density, toxicity, and corrosive gas emission during combustion, analyzes heat release rates, and verifies the ability of cables to maintain circuit integrity while under direct flame impingement.

Detailed Information

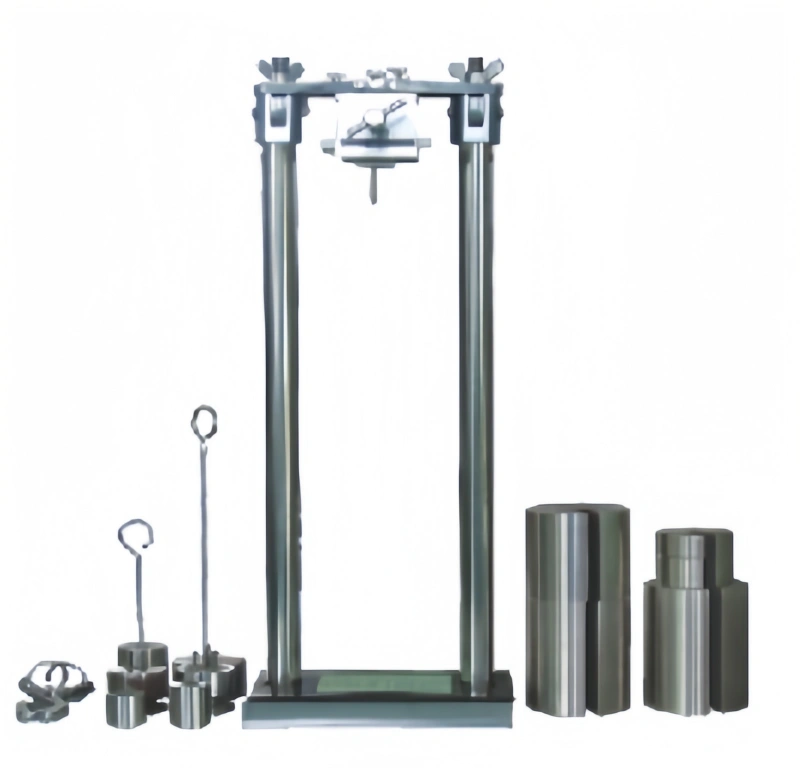

Purpose: Tests plugs/sockets for resistance to impact after freezing at -15±2°C for 16 hours.

Standards: GB 2099.1, GB 2951.14

Key Specs:

Hammers: 100g to 1500g (multiple weights, ± tolerance).

Drop Height: 100 mm.

Dimensions: 250×130×520 mm.

Purpose: Damp heat resistance testing for electrical switches.

Standards: GB/T 2423.3, GB/T 16915.1

Key Specs:

Temperature: 40°C.

Humidity: 91-95% RH (adjustable).

Power: 220V AC, 1 kW.

Purpose: Applies a 2.5N load to insulated pins at 200±5°C.

Standards: GB 2099.1

Key Specs:

Weight: 2.5N.

Dimensions: 60×40×150 mm.

Purpose: Tests withdrawal force and lateral stress for sockets rated ≤250V, ≤16A.

Standards: GB 2099.1

Key Specs:

Rated Value | Number of Poles | Withdrawal Force (N) | |

Multi-Prong Gauge (Max) | Single-Prong Gauge (Min) | ||

≤250V, ≤10A | 2 | 40 | 1.5 |

3 | 50 | – | |

≤250V, >10A – ≤16A | 2 | 50 | 2 |

3 | 54 | – | |

Lateral Force: | ≤250V, ≤16A sockets: 5 N | ||

Purpose: Tests mechanical strength of switches against impact.

Purpose: Tests mechanical strength of switches against impact.

Standards: GB 16915.1, GB 2099.1

Key Specs:

Impactor: 250±1g hemispherical head (10mm radius).

Purpose: Ignitability testing for electrical components (switches, sockets, breakers) and insulating materials.

Standards: GB/T 5169.10-11

Key Specs:

Wire Temp.: 0-1000°C.

Power: 220V AC, 600W.

Purpose: Tests anti-shock function of switches, sockets, and circuit breakers.

Standards: GB/T 16842, GB 16915.1, GB 2099.1, GB 10963.1/.2, GB 4028/IEC 60529

Key Specs:

Output: 48V AC.

Power: 220V AC, 15W.

Purpose: Perform breaking capacity, normal operation, and mechanical/electrical endurance tests for switches, sockets, and circuit breakers.

Standards: GB 16915.1, GB 2099.1, GB 10963.1

Key Specs:

Electronic Load Bank Series | JSW-FZ-A1 | JSW-FZ-A3 | JSW-FZ-4B | JSW-FZ-4C | JSW-FZ-4 |

Control Method | Touchscreen | Analog Meter | Analog Meter | Analog Meter | Analog Meter |

Power Supply | 220V, 5 kVA | 220V, 20 kVA | 220V, 5 kVA | 220V, 5 kVA | 220V, 20 kVA |

Voltage Adjustment Range | 0 ~ 250 V | ||||

Output Channels | 1 | 3 | 1 | 3 | 3 |

Current Range | 2.5 ~ 20 A | 2.5 ~ 63 A | 2.5 ~ 20 A | 2.5 ~ 20 A | 2.5 ~ 63 A |

Power Factor Range | 0.2 ~ 0.9 | ||||

Dimensions (mm) | 880×680×1750 | 1610×680×1710 | 880×680×1750 | 880×680×1750 | 1610×680×1710 |

Weight | 170 kg | 400 kg | 170 kg | 170 kg | 400 kg |

Switch/Socket Life Tester Series | JSW-KCS-A1 | JSW-KCS-A3 | JSW-KCS-C | JSW-KCS-B | |

Test Stations | 1 | 3 | 1 | 3 | |

Rated Voltage | 220 V | ||||

Air Pressure | < 0.8 MPa | ||||

Cycle Frequency | 7.5, 15, 30 cycles/min | ||||

Dimensions (mm) | 1250×770×1100 | 1065×515×960 | |||

Weight | 120 kg | 160 kg | 120 kg | 160 kg | |

Modelo | JSW-DS-B | JSW-DS-A | |||

Rated Voltage | 220 V | ||||

Air Pressure | < 0.8 MPa | ||||

Cycle Frequency | 2, 4, 7.5, 15, 30 cycles/min | ||||

Dimensions (mm) | 1200×500×1100 | 750×440×920 | |||

Weight | 80 kg | 80 kg | |||

Purpose: Temperature rise, continuous operation (28-day), and automatic tripping tests for switches, sockets, and breakers.

Standards: GB 10963.1/.2, GB 16917.1, GB 16915.1, GB 2099.1

Key Specs:

Current: 0-630A.

Temp. Measurement: 0-1000°C.

Samples: 3.

Power: 380V AC, 9 kVA.

Purpose: Temperature rise testing for switches and sockets.

Standards: GB 16915, GB 2099

Key Specs:

Samples: 6.

Power: 220V AC, 9 kW.

Purpose: Tests flame retardancy of single insulated wires/cables (vertical flame propagation).

Standards: GB/T 18380.11/.12/.13/.21/.22

Key Specs:

Gas Flow Control: Propane & air mass flow meters (±1%).

Weights: Standard hooks: 5N, 10N, 15N, 20N, 30N.

Power: 220V AC, 0.1 kW.

Heat Output: 1 kW.

Purpose: Measures halogen acid gas content, pH, and conductivity from burning cables.

Standards: GB/T 17650.1/.2

Key Specs:

Temp. Control: 0-1000°C.

Flow Meter: 0.1-1 L/min adjustable.

Power: 220V AC, 6.5 kW.

Purpose: Evaluates flame propagation resistance of vertically mounted bunched cables.

Standards: GB/T 18380.31/.32/.33/.34/.35/.36 (IEC 60332-3 series)

Key Specs:

Chamber: 1000×2000×4000 mm (W×D×H).

Ladders: Standard (500×3500 mm) or wide (800×3500 mm).

Flow Control: Air: 4.5-10 m³/min; Propane: 0-20 L/min; Compressed Air: 0-100 L/min.

Power: 380V AC, 11 kW.

Purpose: Evaluates flame spread, heat release, and smoke production of bunched cables.

Standards: GB/T 31248

Key Specs:

Chamber: 1000×2000×4000 mm.

Ladders: Standard (500×3500 mm) or wide (800×3500 mm).

Ignition Source: Ribbon burner with 242 holes (1.32mm dia.).

Gas Control: Propane/air mass flow control.

Analysis: Oxygen (0-25%) and CO2 (0-10%) analyzers.

Power: 380V AC, 15 kW.

Purpose: Fire integrity testing under ≥750°C flame alone or ≥830°C flame with mechanical shock.

Standards: GB/T 19216.1/.2/.3/.11/.21/.23 (IEC 60331 series)

Key Specs:

Voltage Output: 0-1000V AC, 3A per phase.

Purpose: Measures smoke density from burning cables under specific lab conditions.

Standards: GB/T 17651.1/.2

Key Specs:

Chamber: 3×3×3 m (user-provided).

Light System: Halogen lamp source (12V, 100W) and silicon photoelectric cell receiver.

Beam Path: 3 m.

Ventilation Fan: For smoke distribution.

Includes: Computer with software and printer.

This suite of electrical and cable testing equipment has a core purpose: to simulate the various harsh environments products may encounter in the real world, identify potential safety hazards in advance, and ensure they are safe and durable enough. The equipment primarily tests from five key aspects:

Simulating Extreme Environments

Some devices create extreme conditions to see if products will be damaged or fail. For example:

Cold Resistance & Impact Test: First, plugs or sockets are frozen to -15°C to make them brittle, then struck with a weight hammer to check for cracking.

Damp Heat Resistance Test: Switches are placed in a high-temperature, high-humidity chamber, simulating long-term exposure to environments like bathrooms, to check for internal rust or short circuits.

Testing Material Strength and Durability

This part focuses on the performance of the product materials themselves. For example:

High-Temperature Pressure Test: The plastic part of a plug is heated to 200°C and pressure is applied to see if it deforms or softens excessively.

Fire Resistance Tests:

Glow-Wire Test: A super-heated wire touches components or materials to check how easily they ignite.

Acid Gas Test: Cables are burned, and the smoke is analyzed to see if it contains large amounts of toxic, corrosive acidic gases.

Endurance Tests: Mechanical Life Test: Machines repeatedly plug/unplug connectors, toggle switches, or cycle circuit breakers tens of thousands of times to simulate years of wear and tear.

Measuring Electrical Safety Performance

This part directly examines critical safety indicators of the products. For example:

Temperature Rise Test: Switches or sockets carry very high current, and the temperature increase at key points is measured to ensure they don’t overheat.

Fire Integrity Test: Cables are energized and exposed to intense flame to see if they can maintain circuit continuity (keep electricity flowing) for a required time, which is vital for fire alarm and safety systems.

Electric Shock Protection Test: Probes shaped like simulated “fingers” or “tools” probe openings in switch/socket casings to ensure users cannot accidentally touch live internal parts.

Assessing Mechanical Structure Reliability

This part checks if the physical structure of the product is robust. For example:

Withdrawal Force Test: Measures the force needed to pull a plug from a socket, ensuring it’s neither too loose (prone to falling out) nor too tight (hard to remove).

Impact Test: A pendulum impacts the surface of a switch, simulating being hit by an object, to test if the housing remains secure.

Conducting Large-Scale Fire Safety Evaluation

These are advanced tests for how bunched cables perform in real fire scenarios.

Bunched Cable Flame Test: Multiple cables are bundled together as in real installations and burned from below with a large burner to observe how far flames travel up the bundle.

Heat & Smoke Release Test: While burning bunched cables, sophisticated analysis measures the total heat released and the density of smoke produced. This is key data for assessing fire hazard (whether it fuels the fire or hinders escape).

In summary, this equipment acts like a “product safety examination hall.” By simulating challenges like cold, damp, impact, aging, and fire, it comprehensively tests the strength, durability, and safety of electrical products and cables, safeguarding electrical safety from the source.

Development History of Electrical & Cable Testing Equipment

The Foundation Era: Mechanical Durability and Basic Safety (Mid-20th Century)

The earliest testing principles focused on fundamental mechanical integrity and basic safety. Equipment from this era was often purely mechanical or electromechanical. Examples: Manual Impact Testers using drop weights; cam-driven Life Testers.

The Standardization Era: Environmental Simulation and Material Science (1970s-1990s)

As international trade grew, so did the need for harmonized safety standards (like IEC, GB). This drove the creation of specialized equipment to test against precise environmental and material performance clauses. Damp Heat Chambers for corrosion testing; Glow-Wire Testers for ignition resistance.

The Electrical Performance Era: Precision and Endurance (1980s-2000s)

With increasingly complex electrical appliances and distribution systems, testing evolved to rigorously verify electrical performance under load over time. Example: Temperature Rise Testers with high-current loads; programmable Electronic Load Banks.

The Fire Safety Revolution: Large-Scale and Hazard-Centric Testing (1990s-Present)

Catastrophic fires highlighted the role of cables in flame spread and toxicity. This triggered a revolution in large-scale, holistic fire performance testing. Large-scale Bunched Cable Flame Chambers; Heat Release Rate (HRR) Testers using oxygen calorimetry.

The Integration and Intelligence Era (2000s-Present)

The current trend is towards integration, automation, and data intelligence. Modern Comprehensive Testers integrate multiple test stations. Example: Touchscreen-controlled Comprehensive Test Stations; PC-based Smoke Density Analyzers with automated reporting.